MIC 12-12-1 Beverage Bottling Equipment (Speed 800-1500BPH)

Working Principle of the Beverage Bottling Machine

The beverage bottling equipment operates through a highly efficient and automated process, ensuring high-quality and consistent production for all types of beverages, including carbonated drinks, juices, and bottled water. The process begins with empty bottles being conveyed to the machine, where they are first cleaned and sterilized to ensure hygiene standards. The next step involves the beverage bottle filling machine, which accurately fills the bottles with the desired beverage. This stage is vital for ensuring that the bottles are filled to the correct level, preventing overfilling or spillage.

The beverage bottling equipment continues its operation with the capping system, where bottles are sealed tightly to preserve the beverage's freshness. The machine’s control system manages the entire process with precision, reducing the risk of human error. Finally, the bottles are passed to the labeling section, where they are automatically labeled with product information, ready for packaging.

This fully automated system is designed to handle various bottle sizes and beverage types, providing the flexibility that modern manufacturers require. The versatility and automation make it an ideal solution for businesses seeking to optimize their production lines with minimal downtime and maximum efficiency.

|

|

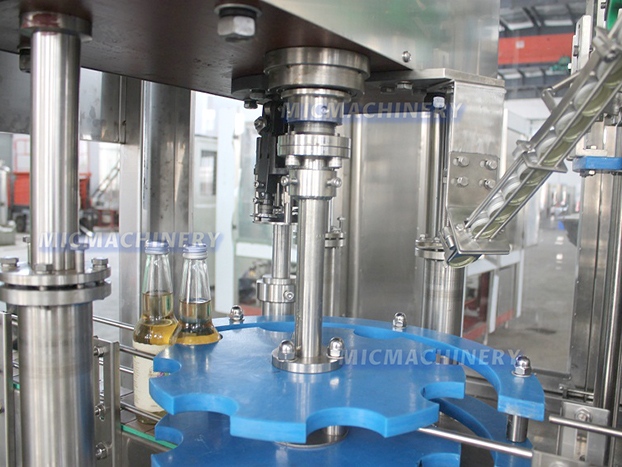

Capping Part |

|

Filling part The filling part of the MIC 12-12-1 beer bottle filler ensures precise and efficient filling with minimal wastage. It uses gravity or pressure filling methods, providing accurate fill levels for various bottle types.

|

|

|

|

|

Advantages of the Beverage Bottling Machine

1、High Efficiency and Speed

The beverage bottling equipment is engineered for speed, with a capacity to fill, cap, and label bottles quickly. This allows for increased production output while maintaining high levels of accuracy. With automation, the machine can operate 24/7, maximizing the overall production rate.

2、Cost-Effective

The real beverage soda bottling machine price is highly competitive, making it an attractive investment for businesses of all sizes. This cost-effectiveness ensures that manufacturers can enjoy the benefits of modern bottling technology without exceeding their budget. Additionally, the machine's efficiency reduces labor costs and minimizes wastage, contributing to a better return on investment.

3、Versatility in Beverage Types

The beverage bottle filling machine is capable of handling a wide variety of beverages, such as soft drinks, energy drinks, teas, and still or sparkling water. This versatility makes the system highly adaptable to different market demands and product types, providing flexibility for beverage producers.

4、Durability and Reliability

Built with high-quality materials, this beverage bottling equipment is designed for long-lasting performance. It is capable of withstanding continuous operation in high-demand environments, making it a reliable choice for businesses that require machinery that can perform consistently over time. The durable construction ensures reduced downtime and maintenance costs.

5、Reduced Labor and Operational Costs

Thanks to its fully automated nature, the beverage bottling equipment significantly reduces the need for manual labor. This leads to a more streamlined production process and lower operational costs. With fewer manual steps involved, the likelihood of errors is reduced, ensuring that each product meets quality standards.

6、Easy Maintenance and Operation

The beverage bottle filling machine is designed for easy maintenance and operation. The intuitive control panel allows operators to monitor and adjust settings with ease. Additionally, the machine is equipped with self-diagnosis features that alert operators to any issues, minimizing downtime and ensuring smooth operations.

7、Space-Saving Design

Despite its high capacity, this beverage bottling equipment features a compact design that can be integrated into various production line setups. This space-saving feature is ideal for businesses with limited production space, allowing them to maximize their facility's available area.

8、Hygienic and Safe Operation

The system includes built-in sterilization and cleaning functions that ensure bottles are hygienically prepared for filling. The use of advanced technologies ensures that the process adheres to food safety regulations, providing peace of mind for beverage producers concerned with product safety.

9、Scalability

The MIC 12-12-1 beverage bottling equipment is scalable to meet the growing needs of businesses. It can handle a range of production volumes, making it suitable for both small and large-scale operations. This scalability ensures that as your business grows, the machine can continue to support your expanding production capacity.

In conclusion, the MIC 12-12-1 beverage bottling equipment offers significant advantages for beverage manufacturers looking for high efficiency, cost-effectiveness, and versatility. With its durable construction, user-friendly interface, and ability to handle a wide variety of beverages, it provides an ideal solution for modern bottling lines. By investing in this advanced beverage bottle filling machine, businesses can achieve optimal performance and reduce operational costs, ultimately enhancing their bottom line.

|

Model No. |

12-12-1 |

18-18-1 |

18-18-6 |

24-24-6 |

32-32-8 |

|

Rinsing Heads |

12 |

18 |

18 |

24 |

32 |

|

Filling Heads |

12 |

18 |

18 |

24 |

32 |

|

Capping Heads |

1 |

1 |

6 |

6 |

8 |

|

Filling Speed |

500-1000BPH |

800-1500BPH |

2000-4000BPH |

4000-5000BPH |

4800-7500BPH |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |