Juice Filling Machine

1.Juice Filling Machine – High-Efficiency Beverage Packaging Solution

2. Precision, Hygiene & Speed in Every Drop

3.Why Choose Jiangsu Mic Machinery?

4.Flow Diagram OF Automatic Juice Filling Machine Price

5.Key Features of Our Juice Filling Machines

6.Solutions for Every Juice Type

7.Affordable and Scalable Options

8.Complete Juice Filling Line Integration

Juice Filling Machine – High-Efficiency Beverage Packaging Solution

At Jiangsu Mic Machinery, we specialize in manufacturing high-performance juice filling machines designed to meet the demanding standards of the modern beverage industry. From fruit juice to herbal drinks, our machines ensure accurate filling, hygienic operation, and seamless integration with your production line. Whether you're producing fresh litchi juice or bottled blends for export, we deliver intelligent filling systems tailored to your needs.

🍹 Precision, Hygiene & Speed in Every Drop

Our juice filling machines are built with food-grade stainless steel, advanced flow control, and automatic temperature regulation systems. They are suitable for PET, glass, or composite packaging across various volume requirements.

Whether you are seeking a hot juice filling machine for thermal-sensitive products or a fully automatic juice filling machine for high-speed bottling lines, our solutions combine advanced engineering with user-friendly design to guarantee performance and consistency.

Bottled Juice Filling Machine:

| Model | MIC 12-1 | MIC 8-8-3 | MIC 14-12-5 | MIC 18-18-6 | MIC 18-18-6 | MIC 24-18-6 | MIC Linear |

| Application | Juice, Cold Coffee, Herbal Tea, Non-carbonated Drinks And So On | ||||||

| Packing Type | Aluminum Bottle, Metal Bottle, Tin Bottle, PET Bottle, etc | ||||||

| Speed | 500-2000BPH | 2000-2500BPH | 3000-5000BPH | 8000-15000BPH | 8000-10000BPH | 10000-13000BPH | 1800BPH |

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||||

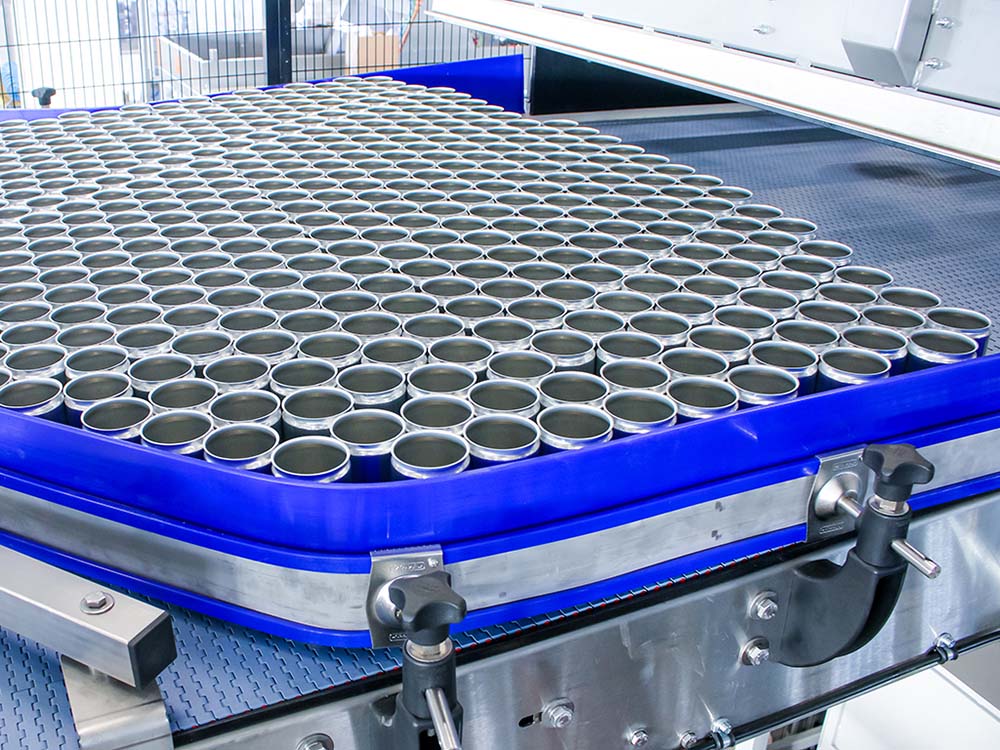

Can Juice Filling Machine:

| Model | MIC 12-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 | MIC 40-10 |

| Application | Juice, Cold Coffee, Herbal Tea, Non-carbonated Drinks And So On | ||||

| Packing Type | Aluminum Cans, Tin Cans, PET Cans, etc | ||||

| Speed | 1000-2000CPH | 4000-7000CPH | 4000-8000CPH | 10000CPH | 12000CPH |

| Filling Arrange | 130ml,250ml, 330ml, 355ml, 500ml, 120z, 16oz, 1L and so on (0.1-1L) | ||||

| Powder | 1.1KW | 2.5KW | 3.5KW | 4.2KW | 5.5KW |

| Size | 1.8*1.3*1.95 (M) | 2.3*1.4*1.9 (M) | 2.58*1.7*1.8 (M) | 2.8*1.7*1.95 (M) | 3.0*1.9*2.1 (M) |

| Weight | 1800KG | 2500KG | 3000KG | 3800KG | 4500KG |

🧃Flow Diagram OF Automatic Juice Filling Machine Price

|

Water Treatment Equipment

|

|

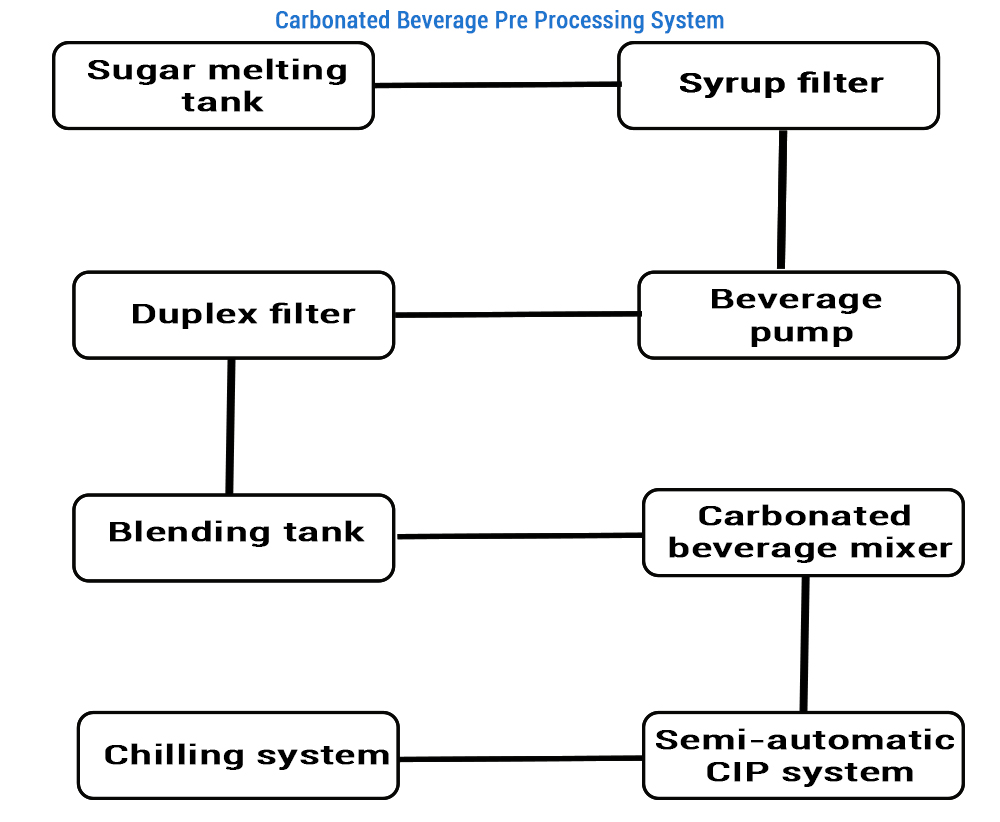

Carbonated Beverage Pre Processing System

|

|

|

|

Plastic Bottle Blowing Machine

|

|

|

|

|

|

|

|

Juice Pet Bottle Filling Machine

|

|

Juice Glass Bottle Filling Machine

|

|

Warm Irrigation Machine

|

|

|

|

|

|

Shrink sleeve labeling machine

|

|

Laser Batch Coding Machine

|

|

Wrap packing machine/Carton packing machine

|

|

|

|

|

🔧 Key Features of Our Juice Filling Machines

|

|

|

✅ Solutions for Every Juice Type

From exotic fruit drinks to pulp-rich blends, our machines support a wide variety of juices. For sterile bottling, the aseptic juice filling machine ensures bacteria-free environments and extended shelf life—ideal for juice exports and high-acidity formulas. Looking to enter the bottled juice business? Our complete juice making and packing machine solution covers everything from blending and homogenizing to filling, sealing, and labeling. For specialty production, such as tropical litchi beverages, our litchi juice packing machine ensures delicate flavor preservation with accurate dosing and minimal waste. |

💰 Affordable and Scalable Options

We understand that budget plays a major role in equipment selection. Our automatic juice filling machine price varies depending on speed, capacity, and customization, but every system is designed for maximum return on investment. Whether you’re a startup or an established brand upgrading your line, we help you find the best-fit system that balances cost and capability. |

|

📦 Complete Juice Filling Line Integration

Jiangsu Mic Machinery offers turnkey packaging solutions, including:

-

Bottle unscramblers

-

Sterilizers and pasteurizers

-

Hot juice filling machine modules

-

Cappers and labelers

-

Inkjet printers and shrink wrappers

We customize every line to match your bottle shape, cap style, and packaging flow, ensuring consistent output and low downtime.

📞 Request a Quote

Looking for a smart, durable, and high-speed juice filling machine for your production line? Contact Jiangsu Mic Machinery today to get expert recommendations and detailed quotations for your next aseptic juice filling machine, juice making and packing machine, or litchi juice packing machine.

📧 Email: lewis@micmachinery.com

📞 Phone: 0086-13961211672

|

The MIC 12-1 Juice Canning Machine offers efficient canning for juice production, with a capacity of 1000-2000 cans per hour. Designed for precision and reliability, it ensures high-quality sealing, making it ideal for small to medium-sized beverage manufacturers. |

|

The MIC 18-6 Fully Automatic Juice Can Filling Machine delivers top-notch performance, filling 4000-7000 cans per hour. With advanced automation and precision, it ensures efficient, reliable, and high-speed production for juice manufacturers. |

|

The MIC 12-1 juice bottling machine for sale offers efficient, automated filling for 500-2000 bottles per hour. Built with precision, it ensures accurate liquid filling, hygienic design, and seamless integration into production lines. |

|

The MIC 18-18-6 fruit juice bottling machine delivers high-speed efficiency, filling 8000-15000 bottles per hour. With advanced automation, precise filling, and durable construction, it ensures reliable performance for large-scale juice production. |

|

The MIC 24-18-6 juice glass packing machine offers efficient filling and capping for 10,000-13,000 bottles per hour. Designed for precision and hygiene, it ensures smooth operation, consistent quality, and is perfect for large-scale glass bottle juice production. |

|

The MIC 8-8-3 PET Juice Bottling Equipment (2000-2500BPH) is designed for high-speed juice production, with a capacity of 2000-2500 bottles per hour. It ensures precise filling, capping, and labeling for efficient, large-scale bottling operations. |

|

The MIC14-12-5 Juice Bottle Filling and Sealing Machine (3000-5000 BPH) is designed for high-speed juice bottling. With a capacity of 3000-5000 bottles per hour, it ensures accurate filling, sealing, and capping, optimizing production efficiency for large-scale operations. |

|

The MIC 18-18-6 Juice Bottling Machine (8000-10000 BPH) is built for high-capacity juice production. With a filling speed of 8000-10000 bottles per hour, it offers precise filling, capping, and labeling, maximizing efficiency in large-scale bottling operations. |