Reliable Can Seaming Machines for High-Speed Production

At Jiangsu Mic Machinery, we manufacture durable, precise, and fully automated can seaming machine solutions to streamline your can packaging process. Our advanced engineering ensures tight, leak-proof seams for all types of cans—whether aluminum, tin, or steel—delivering consistent performance for food, beverage, chemical, or pharmaceutical industries.

🥫 What Is a Can Seaming Machine?

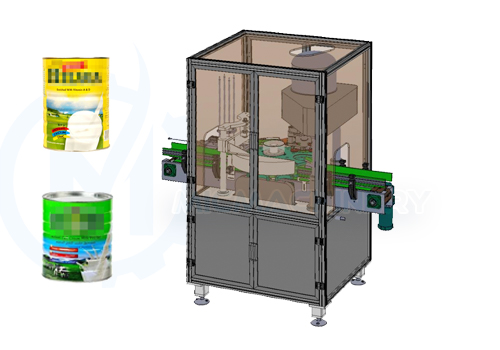

|

A can seaming machine is essential equipment used to seal lids onto filled cans, creating an airtight and secure seal. This process, called “seaming,” is critical to preserving product quality and extending shelf life. Our machines work seamlessly with both flat-top and pull-ring lids, and are compatible with round cans of various materials.

Whether you're working with tinplate or aluminum containers, a high-quality can sealing machine ensures no leakage, corrosion, or spoilage.

|

⚙️ Advanced Features of Our Can Sealing Systems

|

Jiangsu Mic Machinery offers an extensive range of machines,

from semi-automatic to fully automated systems. Our automatic

can sealing machine lineup includes:

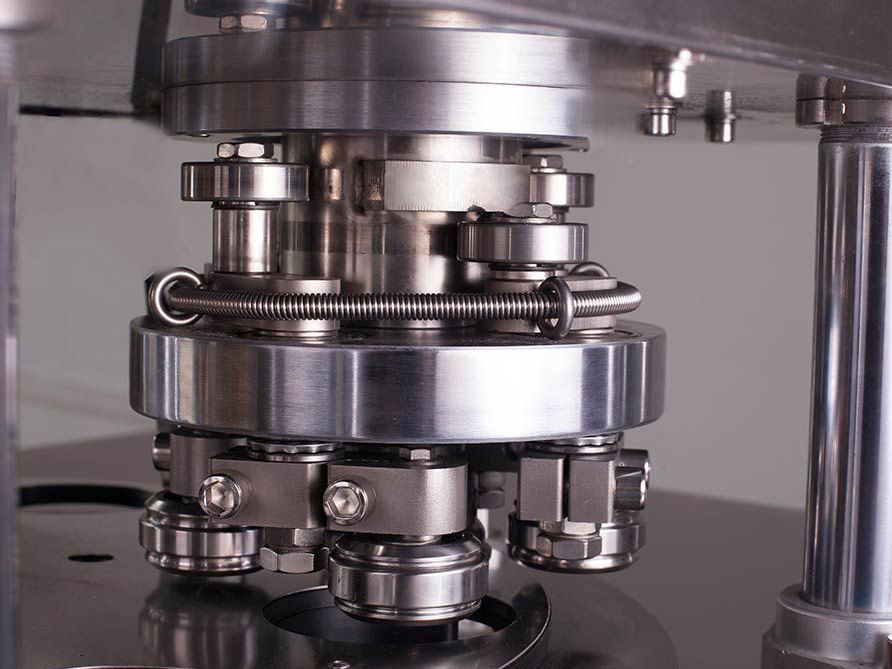

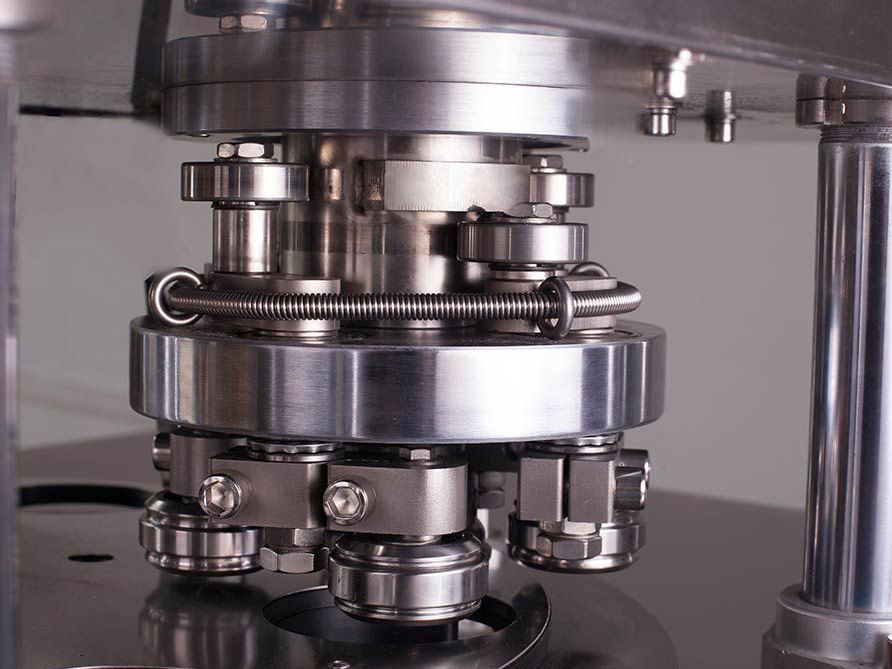

• High-speed double or four-roller seaming heads

• Stainless steel food-grade structure

• Smart PLC controls with touchscreen interface

• Vacuum or nitrogen flushing systems (optional)

• Compatibility with multiple can diameters and heights

Our automatic can seamer and automatic can seamer machine

units provide industrial-level speed and uniformity for production

lines that require both precision and output volume.

|

|

🧃 Tin Can Sealing Machines for Diverse Applications

|

Looking for a versatile tin can sealing machine for packaging powder, juice, soup, or pet food? We’ve got you covered. These machines are optimized for sealing tinplate cans across a variety of industries, ensuring long-term storage and visual appeal.

• Jiangsu Mic Machinery’s systems are ideal for:

• Food & beverage factories

• Paint & chemical companies

• Pharmaceutical and nutraceutical manufacturers

|

📐 Can Seaming Machine Technical Specifications

Milk Powder Can Seaming Machine:

|

Model

|

Milk Powder Can Seaming Machine

|

High-speed Milk Powder Can Seaming Machine

|

Vacuum Nitrogen Milk Powder Can Seaming Machine

|

|

Seaming Heads

|

1

|

1

|

1

|

|

Production Capacity

|

15-25 cans/min

|

15-45 cans/min

|

5-7 cans/min

|

|

Can Diameter

|

Φ99-127mm

|

Φ65-127mm

|

Φ99-153mm

|

|

Can Height

|

100-240mm

|

80-180mm

|

100-240mm

|

|

Power

|

1.5KW

|

2.2KW

|

1.5KW

|

|

Weight

|

720KG

|

650KG

|

860KG

|

|

Diamensions

|

1800*920*1700mm

|

1600*900*1800mm

|

2200*1100*1650mm

|

High-speed Can Seaming Machine:

| Model |

MIC-4A |

MIC-6 |

| Number of Capping Head |

4 |

6 |

| Production Capacity |

30-250 cans/min |

60-400 cans/min |

| Can Diameter |

Φ52.3-99mm

(Special specifications are 105mm)

|

Φ52.3-99mm

(Special specifications are 105mm)

|

| Can Height |

39-160mm |

39-160mm |

| Power |

5.5KW |

7.5KW |

| Weight |

1500KG |

2000KG |

| Dimensions |

2200*1300*1900mm |

2750*1650*1900mm |

EOE Can Seaming Machine:

|

Seaming Heads

|

4

|

|

Production Capacity

|

50-250 cans/min

|

|

Cans Diameter

|

Φ52.5-99mm

|

|

Cans Height

|

32-99mm

|

|

Power

|

5.5KW

|

|

Weight

|

1700KG

|

|

Dimensions

|

2800*1700*1900mm

|

Vacuum Can Seaming Machine:

|

Model

|

Vacuum Seaming Machine

|

Big Can Vacuum Seaming Machine

|

|

Seaming Heads

|

1

|

1

|

|

Production Capacity

|

80-100 cans/min

|

28 cans/min

|

|

Cans Diameter

|

Φ52.5-105mm

|

Φ153mm

|

|

Cans Height

|

39-133mm

|

89-265mm

|

|

Power

|

2.2KW

|

2.2KW

|

|

Weight

|

2500KG

|

2200KG

|

|

Dimensions

|

2010*1400*1900mm

|

1250*1300*1900mm

|

⚡ Automatic Can Sealers for Seamless Operations

|

Our automatic can sealer machines are built to handle high-speed workflows while minimizing human intervention. Features include:

• Tool-less can size changeover

• Quick-release parts for easy cleaning

• Vibration-free operation for high sealing precision

• Error-detection alarms and auto shutdown protection

If your production demands consistent sealing quality at scale, our automatic can sealer machine is the smart choice.

|

|

🔁 Integration with Filling and Labeling Lines

|

To maximize productivity, our can sealing machine and can seaming machine models can be seamlessly integrated with:

• Liquid or powder filling systems

• Labeling and coding machines

• Can washing and drying stations

• End-of-line packing solutions

Whether you're upgrading an existing line or building a new one, our automatic can seamer technology ensures a continuous and reliable packaging process.

|

🌍 Why Choose Jiangsu Mic Machinery?

With over 20 years of expertise in packaging technology, Jiangsu Mic Machinery provides tailored equipment for clients across 50+ countries. When you partner with us, you gain:

• Full support from machine design to installation

• Spare parts availability and 24/7 technical assistance

• Customizable can diameter and height ranges

• Cost-effective yet robust sealing machinery

Our machines are CE-certified and built with global industry standards in mind.

📩 Get the Best Can Seaming Machine for Your Business

Looking to buy a durable, high-precision can sealing machine or automatic can seamer for your production line? Contact Jiangsu Mic Machinery today for a custom quote and layout plan.

📧 Email: lewis@micmachinery.com

🌐 Website: www.micbeveragemachine.com

📞 WhatsApp/Phone: 0086-13961211672

Whether you need a compact tin can sealing machine or a fully integrated automatic can seamer machine, we’ll help you find the perfect solution.