1.Soda Filling Machine – Reliable Carbonated Beverage Bottling Solutions

2.Complete Solutions for Soda Bottling

3.Why Choose Jiangsu Mic Machinery?

4.Soda Filling Machine Parameter Table

5.Flow Diagram OF Soda Bottling Equipment

7.Soda Bottle Plant Price & Value

Soda Filling Machine – Reliable Carbonated Beverage Bottling Solutions

At Jiangsu Mic Machinery, we specialize in manufacturing advanced soda filling machines designed to handle all types of carbonated drinks efficiently and hygienically. From startup brands to large-scale beverage factories, our systems support complete automation, semi-automation, and manual operations. Whether you're filling PET bottles, glass bottles, or cans, we provide precision-built solutions tailored to your production scale and packaging requirements.

🥤 Complete Solutions for Soda Bottling

Our equipment line covers a wide range of soda production needs—from small scale soda bottling equipment to large-capacity production systems. Designed with precision-engineered valves and CO₂ pressure balancing technology, our machines ensure accurate filling without excess foaming or liquid loss. Each unit is built with food-grade stainless steel and conforms to international hygiene standards.

For beverage startups, we offer cost-effective options such as the manual soda bottle filling machine, ideal for short runs and pilot batches. Growing businesses can benefit from our semi automatic glass bottle soda filling machine, which provides the perfect balance between automation and affordability.

🏆 Why Choose Jiangsu Mic Machinery?

|

Soda Filling Machine Parameter Table

Bottled Soda Filling Machine:

| Model | MIC12-12-1 | MIC18-18-1 | MIC24-24-6 | MIC24-24-8 | MIC32-32-8 | MIC Semi Automatic | MIC18-18-6 |

| Application | Beer, Carbonated Beverage, Gas Drinks, Sparking Water And So On | ||||||

| Packing Type | Aluminum Bottle, Metal Bottle, Tin Bottle, etc | PET Bottle | |||||

| Speed | 300-1500BPH | 1000-2500BPH | 4000BPH | 2000-6000BPH | 4800-7500BPH | 200-800BPH | 2000-4000BPH |

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||||

| Power | 1.5KW | 1.5KW | 5.0KW | 0.3KW | 2.2KW | ||

| Size | 2.2*1.8*2.55 (M) | 2.5*1.4*2.5 (M) | 3.4*2.5*2.3 (M) | 2.0*0.7*2.0 (M) | 2.5*1.9*2.3 (M) | ||

| Weight | 3500KG | 4500KG | 10000KG | 150KG | 3500KG | ||

🍹Flow Diagram OF Soda Bottling Equipment

|

Water Treatment Equipment

|

|

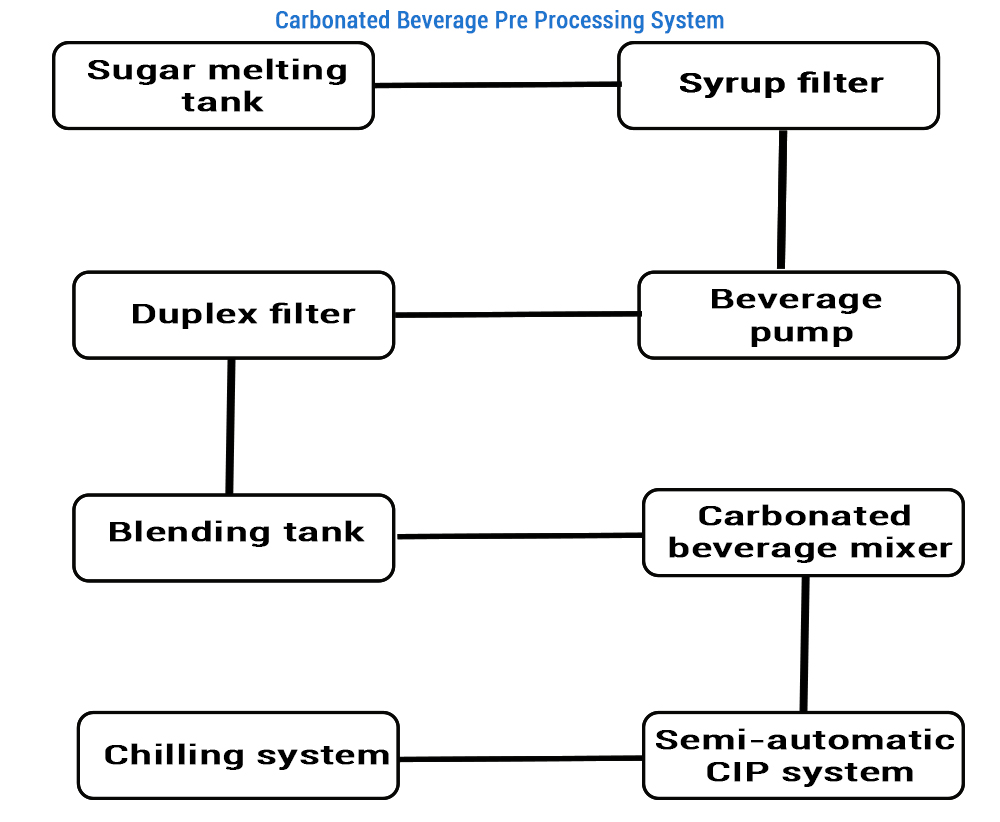

Carbonated Beverage Pre Processing System

|

|

|

|

Plastic Bottle Blowing Machine

|

|

|

|

|

|

Soda Pet Bottle Filling Machine

|

|

Soda Glass Bottle Filling Machine

|

|

Warm Irrigation Machine

|

|

|

|

|

|

Laser Batch Coding Machine

|

|

Wrap packing machine/Carton packing machine

|

|

|

|

|

⚙️ Key Features

|

|

|

💰 Soda Bottle Plant Price & ValueInvesting in a soda bottle filling plant means considering long-term ROI. The soda bottle plant price varies depending on capacity (bottles/hour), degree of automation, bottle type, and required accessories. Jiangsu Mic Machinery offers cost-effective pricing backed by quality craftsmanship and long-lasting machine performance. Some clients prefer to start with basic soda bottling machine for sale units and gradually expand their plant with additional modules. Others choose a full turnkey solution from the start, ensuring seamless line performance and better scalability. |

🧃 Bottle Flexibility

Whether you work with PET, glass, or plastic bottles, our machines can handle it. The pet bottle soda machine is optimized for high-speed production and is widely used in soft drink manufacturing. For eco-conscious or premium soda brands, our glass soda bottle machine ensures accurate filling and capping without compromising on product quality.

We also provide tailored solutions for brands requiring plastic bottle soda filling machine capability with consistent carbonation retention and leak-proof sealing.

📞 Get Your Quote Today

Looking for dependable, cost-effective soda bottling equipment? Contact Jiangsu Mic Machinery today to learn more about our carbonated bottling equipment, semi automatic glass bottle soda filling machine, or soda bottling machine for sale. Let us help you build a high-efficiency soda bottle filling plant tailored to your market.

📧 Email: lewis@micmachinery.com

📞 Phone: 0086-13961211672

|

The MIC 12-12-1 glass bottle soda filling machine offers high-speed, efficient filling with a capacity of 5000-12000 BPH. This advanced machine ensures precise filling, maintains carbonation, and features automatic bottle capping and sealing, making it ideal for large-scale production |

|

The MIC 18-18-1 Glass Bottle Soda Bottling Machine offers high precision and efficiency with a speed of 800-1500 BPH. It ensures reliable filling, capping, and sealing, maintaining product quality for medium-scale production lines. Ideal for carbonated beverages. |

|

The MIC 18-18-1 Soda Bottle Packing Machine offers high efficiency with a speed of 3000-4000 BPH. This advanced machine ensures smooth, accurate filling, capping, and sealing, providing reliable performance for medium-scale soda bottle production lines |

|

The MIC 24-24-6 Automatic Soda Bottling Plant offers a high-speed filling capacity of 3000-5000 BPH. Designed for large-scale production, it efficiently handles filling, capping, and labeling, ensuring high precision and quality control throughout the bottling process. |

|

The MIC 32-32-8 Soda Bottle Filling Machine offers a high-speed filling capacity of 8000-10000 BPH. This advanced machine provides precise filling, capping, and sealing for soda bottles, ensuring high-quality production for large-scale beverage manufacturing. |

|

The MIC Semi-Automatic Soda Bottling Plant offers a speed range of 200-800 BPH, providing an efficient solution for small to medium-scale production. It delivers precise filling, capping, and labeling, offering excellent flexibility and reliability for beverage manufacturers. |

|

|

|||

|

|

|