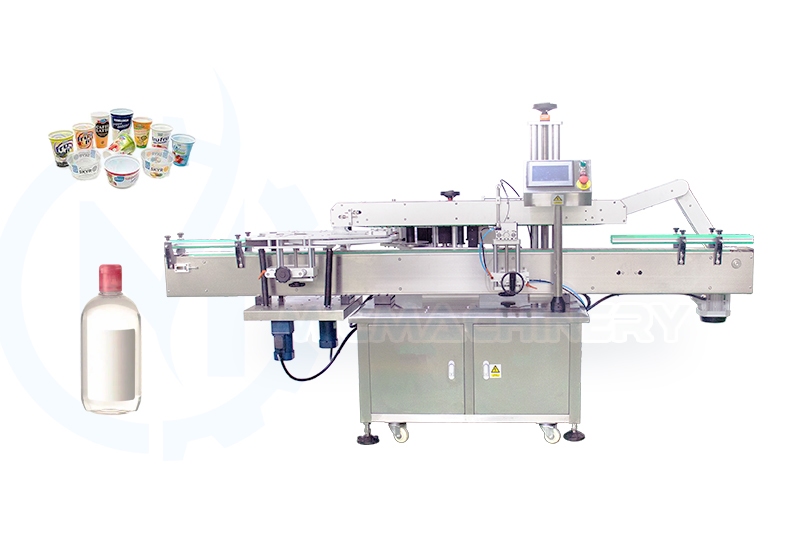

Cup Labeling Machine for All Cup Types

A cup labeling machine is specialized packaging equipment designed to automatically apply labels to various types of cups. These machines play a crucial role in modern production and packaging lines where branding, regulatory information, or product identifiers need to be applied accurately to cup-shaped containers. Whether it's for food-grade yogurt cups, beverage containers, cosmetic jars, or even pharmaceutical cups, these labeling machines ensure clean, precise, and high-speed label application. They can handle different labeling surfaces including the cup body, lids, or bottoms depending on the labeling configuration.

These machines come in several configurations, from manual to fully automated systems, to cater to different production scales. Fully automatic cup labeling machines are particularly beneficial for large-scale manufacturers, where efficiency, speed, and labeling precision are essential. Most models support labeling on cups made of plastic, glass, paper, and metal materials. In today’s fast-paced manufacturing environments, using a dedicated cup labeling solution not only improves product presentation but also guarantees consistency and compliance with international labeling standards.

⚙ Types of Cup Labeling Machines

Cup labeling machines are broadly classified by automation level, labeling method, and cup orientation. Each type serves a specific function, depending on the type of label to be applied and the desired output speed. The three main categories include manual, semi-automatic, and fully automatic cup labeling machines.

➣ Manual machines are best for small batch or artisan operations. Operators physically place the cup and manually control label application. They’re cost-effective but slower and require more labor.

➣ Semi-automatic cup labelers still involve operator interaction but automate the actual labeling mechanism. These systems are ideal for medium-scale businesses looking to increase productivity while maintaining affordability.

➣ Fully automatic machines handle feeding, positioning, and labeling without manual intervention. They can achieve speeds of up to several hundred cups per minute and often include advanced features like sensor-based alignment, label presence detection, and integration with other production systems like filling and sealing machines.

Depending on the labeling requirement, cup labelers can also be classified as wrap-around cup labeling machines, top label applicators for cup lids, double-side cup labeling machines, or tapered cup labelers that can accommodate slanted or uniquely shaped cups. Wrap-around systems are widely used for yogurt or dessert cups, while top labelers are common in coffee-to-go applications.

Additionally, machines vary by cup feeding style—rotary tables, conveyor belts, or star-wheel feeding. The selection depends on space, speed, and automation integration preferences.

⚙ Key Features and Customization Options

Modern automatic cup labeling machines are designed with adaptability and smart technology at their core. Manufacturers looking for high performance and durability benefit from features that enhance labeling precision, reduce downtime, and simplify operation. Some of the most significant features include:

|

☑ Adjustable Labeling Head: Enables operators to quickly adjust the machine for various cup heights and diameters without needing separate tooling for each cup format.

☑ Smart Sensors and Alignment Systems: Optical or mechanical sensors ensure precise label placement, even on cups with logos or embossed branding. Sensors can also detect cup orientation, missing labels, or feeding errors.

☑ Touchscreen HMI Controls: Intuitive interfaces allow for quick setup, diagnostics, and recipe storage. Operators can save cup-specific settings for fast switching between products.

☑ Variable Speed Motors: Synchronization between label feed and conveyor speed minimizes wrinkles and misaligned labels.

|

|

|

☑ Label Rejection Mechanism: Faulty or misapplied labels can be automatically rejected from the production line, helping maintain product quality.

☑ Integration Ready: Most machines can be synchronized with filling, sealing, capping, and shrink-wrapping equipment, forming a seamless packaging line.

Customization options include automatic cup loading systems, custom label applicators for irregular shapes, and multi-label configurations (front and back, top and side). These capabilities ensure that cup labeling machines can be tailored to a wide variety of applications, from standard beverage cups to intricate cosmetic jars or promotional containers.

⚙ Applications Across Industries

Cup labeling equipment serves multiple sectors that rely on cup-style packaging for both functional and aesthetic purposes. From consumer goods to specialized products, labeling is a central part of branding and compliance. Common industries include:

|

|

☑ Food and Beverage: Ice cream, yogurt, dips, sauces, fruit cups, ready meals, and bubble tea often come in branded cups that need accurate and attractive labeling. Tamper-evident or resealable labels are also popular.

☑ Pharmaceuticals and Nutraceuticals: Dosing cups and supplement containers require clear, legible labels containing critical dosage, batch, and expiry information. Labeling accuracy is essential to comply with FDA and other global regulatory standards.

☑ Cosmetics and Personal Care: Small cosmetic cups, masks, and samples are increasingly packaged in stylish containers with wrap-around labels to attract consumers.

|

☑ Chemical and Industrial Products: Cups used for paint samples, adhesives, or cleaning gels also benefit from high-durability labels to withstand handling and environmental exposure.

☑ Hospitality and Catering: For events or custom-branded service, coffee and snack cups are labeled in-house using flexible, fast-swapping machines.

From artisanal dairy producers to global FMCG corporations, cup labeling machines provide the scalability and precision required for branding, regulatory compliance, and supply chain efficiency.

⚙ Advantages of Automated Cup Labeling Systems

Using an automated cup labeling machine offers numerous advantages over manual or hand-labeling processes. These benefits include not only operational efficiency but also improvements in labeling quality, cost reduction, and production flexibility.

|

☞ Increased Production Speed: Automated machines label hundreds of units per minute, far outperforming manual operations. This allows manufacturers to meet high-volume demand without delays.

☞ Consistent Labeling Quality: Advanced positioning and tension control mechanisms ensure labels are placed straight, wrinkle-free, and in the correct spot every time, enhancing brand perception.

☞ Cost Efficiency: Reduces labor requirements and minimizes material wastage due to misapplied or skewed labels. Many businesses report a return on investment within the first year of operation.

|

|

|

☞ Adaptability and Fast Changeovers: Modern machines offer fast, tool-free adjustments between different cup sizes, making them ideal for businesses offering diverse SKUs or seasonal packaging.

☞ Reduced Downtime: Easy maintenance, intelligent error detection, and self-diagnosing software reduce unexpected downtime and keep operations running smoothly.

Furthermore, consistent labeling is essential for retailers and distributors who require barcodes and product information to be scannable and compliant with digital inventory systems.

⚙ How to Choose the Right Cup Labeling Machine

When selecting a cup labeling machine, it is essential to consider your production environment, product range, labeling needs, and growth forecasts. Key questions to guide your decision include:

1)What is your daily or hourly production target? High-speed lines will require a fully automated machine, while small operations may benefit from a semi-automatic solution.

2)What types of cups do you use? Whether they are tapered, round, or lidded cups, different machines are designed for specific geometries.

3)What is the required label position? Side, top, bottom, or wrap-around label placement each demands a different applicator type.

4)Do you plan to scale up or diversify product lines? Machines with flexible labeling heads and quick-change settings are better suited for growing businesses.

5)What is your budget? Pricing varies from a few thousand USD for simple semi-automatic machines to well over $50,000 for integrated, high-speed labeling systems.

Also, prioritize machines from manufacturers with good after-sales support, easy access to spare parts, and training services. Investing in a reliable machine pays off in the long term with fewer stoppages, better output, and consistent label quality.

⚙ Maintenance, Support, and Longevity

Routine maintenance is key to ensuring the longevity and performance of your cup labeling machine. Depending on usage frequency, scheduled servicing can prevent major breakdowns and optimize machine uptime. General maintenance practices include:

|

|

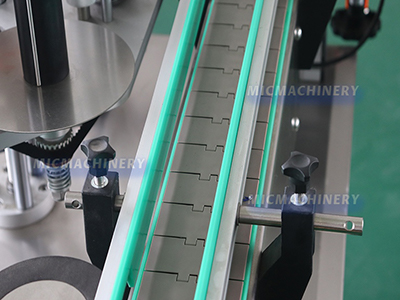

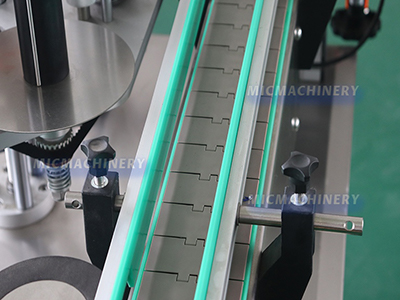

◆ Daily cleaning of rollers, sensors, and label tracks to prevent adhesive buildup or dust interference.

◆ Weekly checks on belt tension, roller alignment, and wear parts like O-rings or label knives.

◆ Monthly inspections of the labeling head, pneumatic components (if any), and lubrication of mechanical elements.

◆ Software updates where applicable to keep the system secure and compatible with new label formats or production data interfaces.

|

Manufacturers typically offer comprehensive support packages including on-site installation, operator training, virtual troubleshooting, and spare part kits. Some high-end labeling systems also include remote monitoring capabilities that notify operators of mechanical or software issues in real-time.

By investing in preventive care, businesses can extend the lifespan of their labeling equipment by several years while avoiding costly downtime. Proper usage and maintenance can keep a cup labeling machine running efficiently for 8–15 years, depending on operating conditions and workload.

⚙ Conclusion

A cup labeling machine is an indispensable part of any packaging line involving cups. Whether for food, cosmetics, or pharmaceuticals, accurate and efficient labeling enhances brand presence, improves traceability, and meets regulatory demands. With a wide variety of models available, businesses can find the right solution to fit their production needs, cup formats, and budget—making it a vital investment for manufacturers aiming to scale, compete, and lead in their market segment.