Showing 1–9 of 8 results

MIC-350B Shrink Sleeve Label Machine (Speed 40 Meter Per Min)

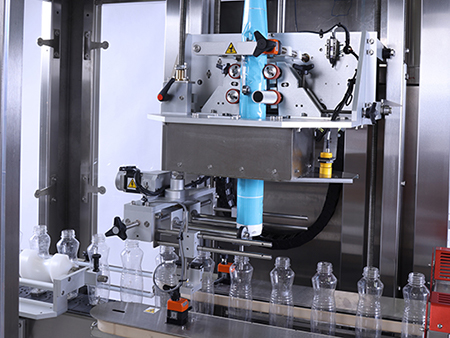

A sleeving machine for bottles is a specialized piece of equipment used in the packaging industry for applying shrink sleeve labels to bottles of various sizes and shapes. These machines use advanced technology to apply labels quickly and accurately, helping you achieve a professional and eye-catching look for your products.

Learn more

MIC-250D Shrink Sleeve Applicator (45 Meter/Min)

A sleeving machine for bottles is a specialized piece of equipment used in the packaging industry for applying shrink sleeve labels to bottles of various sizes and shapes. These machines use advanced technology to apply labels quickly and accurately, helping you achieve a professional and eye-catching look for your products.

Learn more

MIC-150C Shrink Sleeve Equipment (Speed 9000BPH)

Sleever machines, also known as sleeve labeling machines, are used to apply heat-shrinkable sleeves to products such as bottles, cans, and containers. The sleeves are made of plastic or other materials and are designed to fit tightly around the product, providing a label or decoration that covers the entire surface. Sleever machines are commonly used in the food and beverage industry, as well as in the pharmaceutical, cosmetic, and chemical industries.

Sleever machines offer several benefits over traditional labeling methods. They are highly versatile, capable of handling a wide range of product shapes and sizes, and can apply labels at high speeds, making them ideal for high-volume production environments. Additionally, because the labels are applied as sleeves, they can cover irregularly shaped or non-flat surfaces, providing more space for branding and product information.

In this competitive business environment, sleever machines are increasingly important to help manufacturers increase production efficiency, reduce waste and labor costs, and enhance product presentation.

Learn more

MIC-150B Shrink Sleeve Machine (Speed 50 BPM)

An automatic sleeve labeling machine is a type of industrial equipment used for labeling containers, such as bottles, cans, and jars. It offers an efficient and precise labeling solution for various industries, including food and beverage, pharmaceuticals, cosmetics, and other consumer goods. This machine uses sleeves made of materials such as plastic, paper, or shrink film to wrap around the container and provide a label with branding information, nutritional facts, and other essential details. The use of an automatic sleeve labeling machine helps companies to streamline their labeling process, reduce labor costs, and improve overall labeling accuracy. In this article, we will explore the key features and benefits of an automatic sleeve labeling machine and how it can be an asset to your business.

Learn more

MIC-360D Shrink Sleeve Applicator Machine (Speed 600BPM)

Sleeving equipment is used for the application of shrink sleeve labels on various products such as bottles, jars, and cans. These machines provide a high degree of accuracy and efficiency, making them a popular choice for packaging companies across various industries.

Learn more

MIC Heat Shrink Sleeve Machine (Speed 150BPM)

Sleeving equipment is used for the application of shrink sleeve labels on various products such as bottles, jars, and cans. These machines provide a high degree of accuracy and efficiency, making them a popular choice for packaging companies across various industries.

Learn more

MIC Bottle Sleeve Machine (Speed 150BPM)

Sleeving equipment is used for the application of shrink sleeve labels on various products such as bottles, jars, and cans. These machines provide a high degree of accuracy and efficiency, making them a popular choice for packaging companies across various industries.

Learn more

MIC Sleeve Applicator For Bottles

Characteristics:

Manually casing the labels, and then the bottle will be passed into the shrink tunnel, and shrink tightly by steam.

Learn more