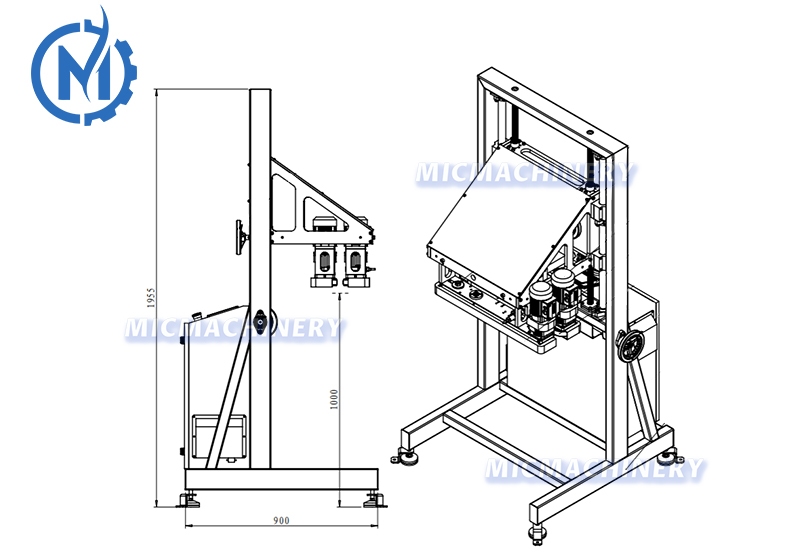

Inner Pressure Detection Machine

⚙ Accurate Internal Pressure Testing for Beverage and Food Containers

The Inner Pressure Detection Machine is specially designed to ensure the safety and quality of sealed beverage and food containers by detecting abnormal internal pressure. With high-speed, non-destructive inspection capabilities, this machine plays a critical role in modern packaging lines—guaranteeing only safe, qualified products proceed to the next stage.

⚙ Advanced Non-Destructive Pressure Detection

Our Inner Pressure Detection Machine utilizes high-sensitivity pressure sensors and intelligent signal processing to carry out non-contact, non-destructive pressure testing. The system continuously monitors internal pressure variations of each passing container in real time, allowing the production line to maintain consistent product integrity.

By comparing internal pressure values against preset thresholds, the machine can instantly distinguish between normal and defective containers. An automatic rejection system then removes non-compliant products without stopping the production line, greatly improving operational efficiency.

⚙ Wide Application Across Packaging Types and Industries

|

This detection system is compatible with a wide range of packaging materials and formats. Whether you're running a high-speed line for carbonated soft drinks, beer, sparkling water, yogurt, or seasoning sauces, the Inner Pressure Detection Machine ensures reliable pressure analysis regardless of container shape or size.

Applicable container types include:

⦾ PET plastic bottles

⦾ Glass bottles

⦾ Aluminum and tin cans

⦾ Composite containers

This makes the machine suitable for applications in beverage plants, dairy factories, breweries, sauce filling lines, and more.

|

|

|

⚙ Intelligent Automation and Easy Integration

Designed for modern manufacturing, the Inner Pressure Detection Machine supports full automation, seamlessly integrating into existing production lines without the need for extensive modifications. It can be installed after filling and capping machines, directly inspecting every product as it exits the sealing process.

Features include:

☑ Real-time data monitoring

☑ Automatic alarm for abnormal pressure detection

☑ Rejector device for defective containers

☑ PLC control system and touchscreen interface

☑ Remote access for system diagnostics and upgrades (optional)

The machine supports communication protocols for centralized production control and quality data management, helping manufacturers optimize performance and traceability.

⚙ Key Benefits of the Inner Pressure Detection Machine

⦾ High-precision pressure detection for all container types

⦾ 100% inspection rate with no interruption to production

⦾ Reduces recalls and improves consumer safety

⦾ Prevents leakage, spoilage, and packaging failure

⦾ Fully automatic with minimal operator intervention

⦾ Improves overall line efficiency and product consistency

⦾ Customizable to suit various bottle shapes, speeds, and pressure thresholds

⚙ Ensure Product Safety and Quality with Confidence

In today’s highly competitive food and beverage market, manufacturers must meet increasingly strict quality and safety regulations. The Inner Pressure Detection Machine provides a dependable solution for internal pressure control—enhancing product reliability, customer satisfaction, and brand trust.

Whether you are upgrading your current production line or building a new facility, this machine is a powerful addition that ensures compliance and boosts your operation’s quality assurance capabilities.

Contact us today to learn more about how the Inner Pressure Detection Machine can be tailored to your production needs. Let our professional team support your factory with industry-leading pressure detection technology.