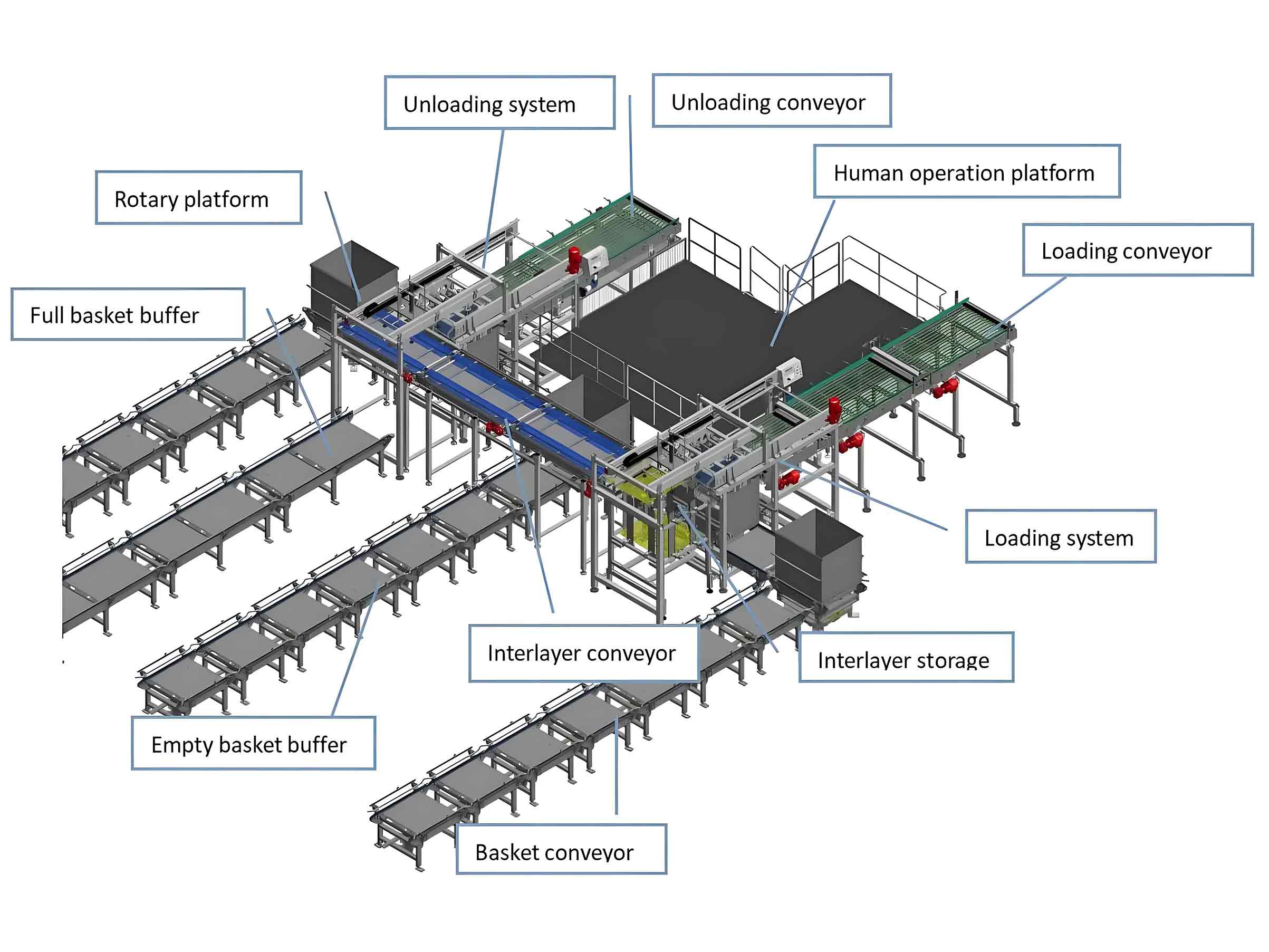

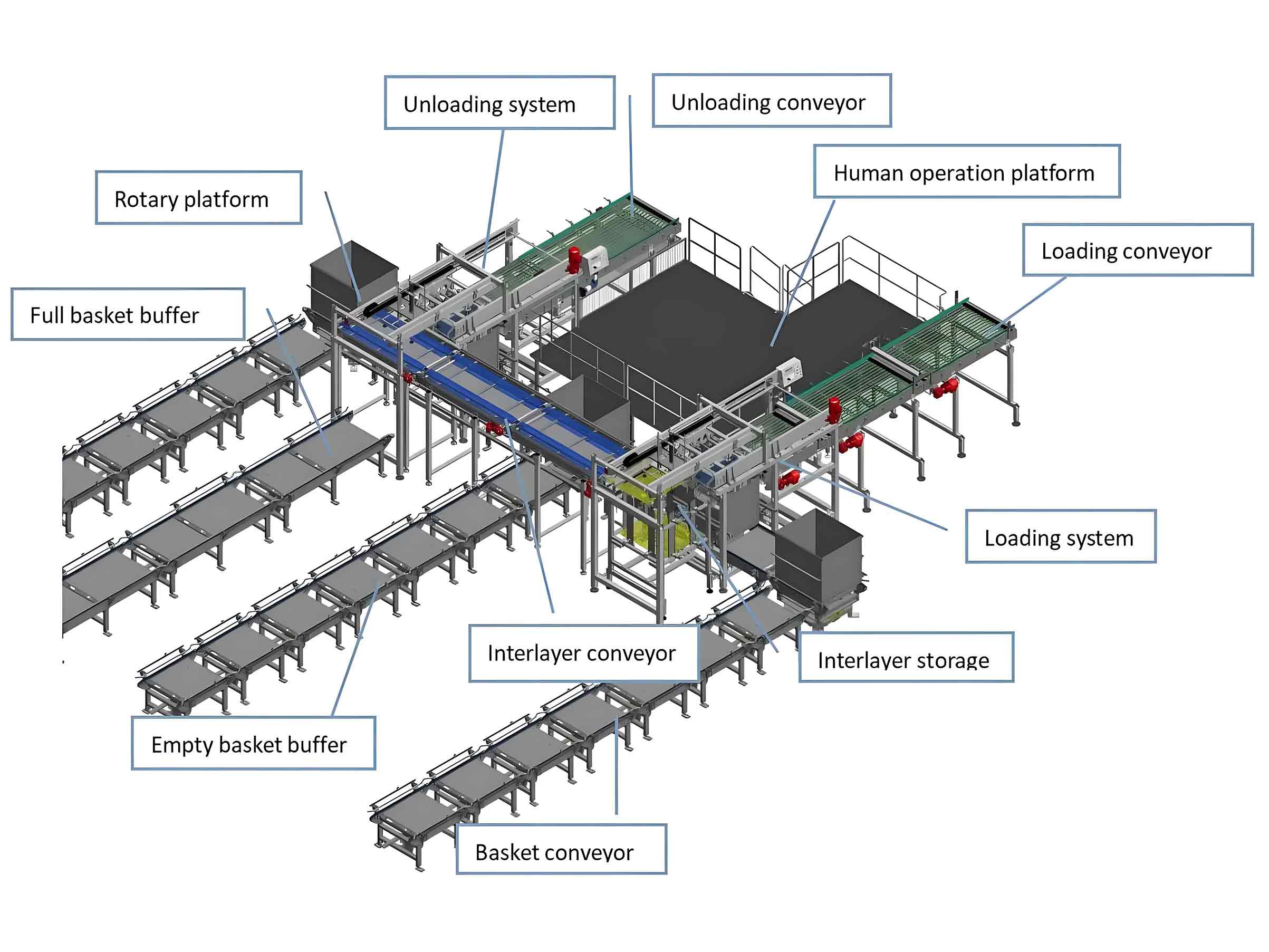

Automatic Basket Loading and Unloading Machine for Streamlined Processing

In modern food, beverage, and pharmaceutical production lines, automation is no longer optional—it’s essential. At Jiangsu Mic Machinery, we design integrated equipment that simplifies high-volume batch processing. One of the key innovations in thermal processing, sterilization, and secondary handling is our automatic basket loading and unloading machine. This advanced system minimizes manual labor, increases throughput, and protects product integrity throughout the production cycle.

✅ What Is an Automatic Loading and Unloading Machine?

|

An automatic loading and unloading machine is designed to efficiently transfer containers (such as cans, pouches, or bottles) into and out of sterilization baskets. It’s a core part of any retort or autoclave line and allows for fully automatic handling of products between filling, sterilization, and packaging stages.

|

🧺 Basket Handling Made Easy

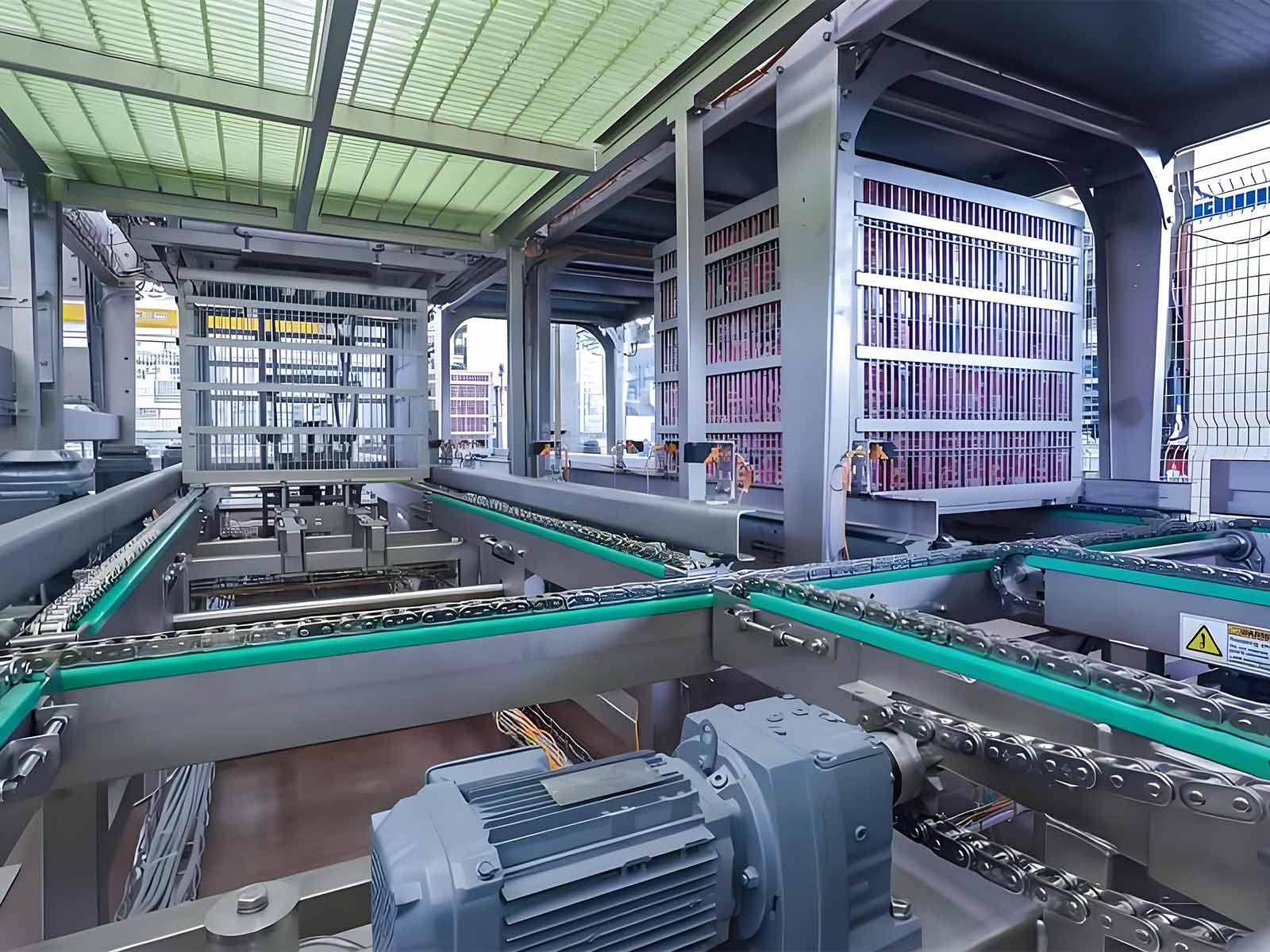

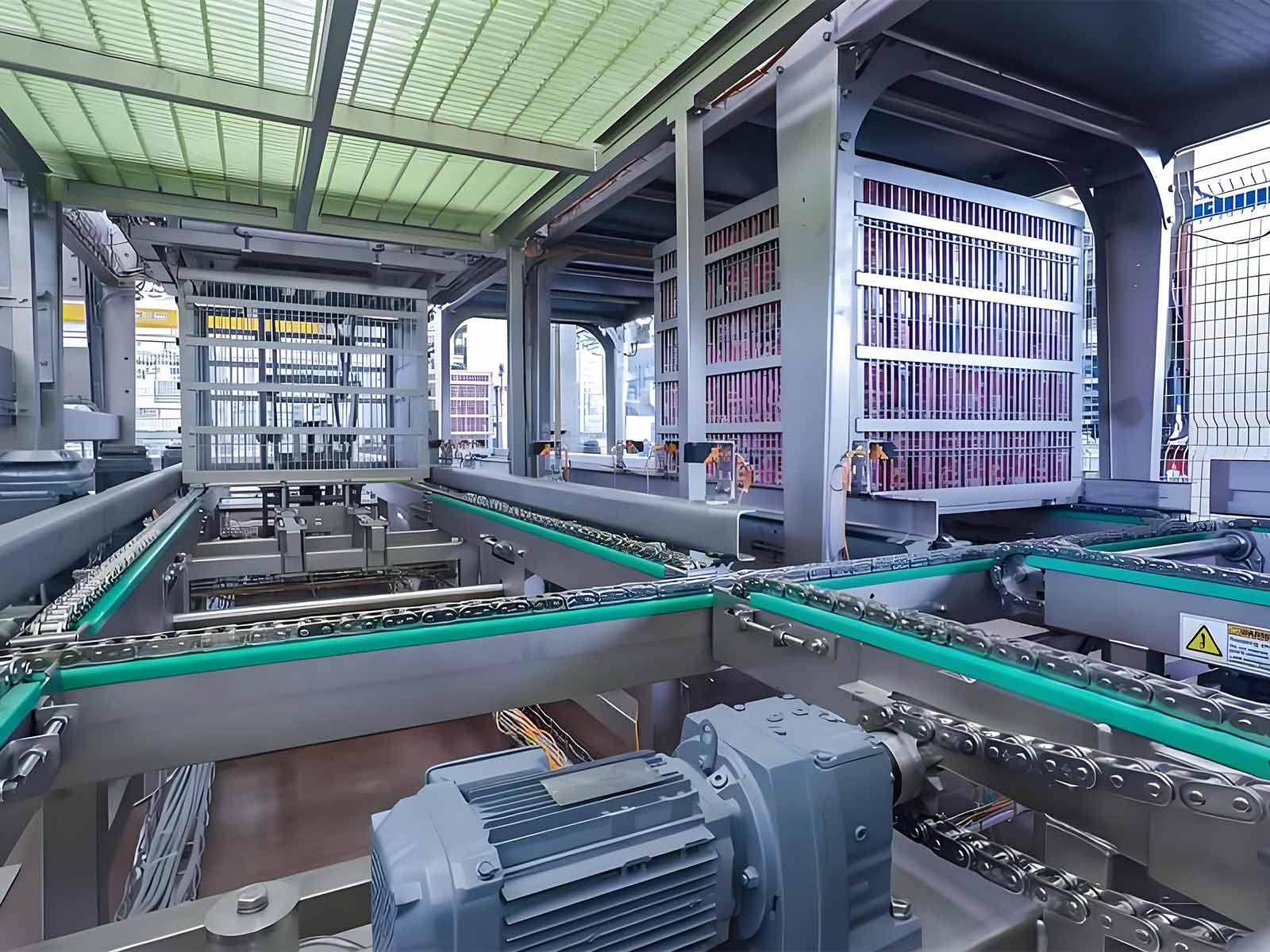

Our automatic basket loading and unloading machine is engineered to handle heavy-duty tasks in the most demanding industrial settings. It can load filled containers into metal baskets for steam sterilization or retort processes, and then unload them post-sterilization—all without human intervention.

|

• Works with metal, stainless steel, or plastic baskets

• Gentle handling to avoid container damage

• Fully programmable to match various product sizes and layouts

• Synchronizes with upstream and downstream equipment

Whether you’re processing canned foods, bottled beverages, or flexible pouches, this machine offers unmatched efficiency and precision.

|

|

🔄 Integrated Loader and Unloader

|

The automatic basket loader and unloader combines two machines into one seamless system. It receives products from the conveyor, places them into sterilization trays or baskets, and automatically removes them after processing.

• Linear or robotic arm configurations available

• Compatible with rotary or batch-type sterilizers

• Designed for continuous or batch processing

• Modular build for flexible factory layout integration

With minimal manual touchpoints, the automatic basket loader and unloader improves hygiene standards, reduces operator fatigue, and ensures consistency in every cycle.

|

📐 Automatic Loading And Unloading Machine Technical Specifications

| Model |

MIC-300 |

MIC-400 |

MIC-600 |

MIC-600A |

MIC-800A |

| Production Capacity |

0-300 cans/min |

200-400 cans/min |

300-600 cans/min |

0-600 cans/min |

0-800 cans/min |

| Using Range |

Various cans, etc |

Various cans, etc |

Various cans, etc |

/ |

/ |

| Power |

4KW |

4KW |

5KW |

5KW |

5.5KW |

| Weight |

/ |

/ |

/ |

5000KG |

5500KG |

| Dimensions (mm) |

According to the customer's workshop location

and the height of the sterilization pot

|

16300*13000*2100 |

18500*14000*2100 |

🏭 Typical Applications

|

Our basket handling solutions are widely used in:

• Food and beverage: Canned vegetables, ready-to-eat meals, milk, sauces

• Pharmaceuticals: IV bags, glass ampoules, plastic vials

• Cosmetics and chemicals: Creams, gels, liquid formulas in containers

If your production includes thermal treatment or extended curing, an automatic loading and unloading machine is vital for maintaining high efficiency and safety.

|

|

🌍 Why Choose Jiangsu Mic Machinery?

|

At Jiangsu Mic Machinery, we go beyond just supplying machines—we deliver complete system integration. Our automatic basket loading and unloading machines are:

• Built from high-grade stainless steel for durability

• Supported by intelligent PLC control and touchscreen HMI

• Customizable for your container type, size, and line speed

• Backed by global after-sales support and spare parts availability

We understand the complexity of sterilization and batch loading systems, and we engineer each solution to help you achieve production goals with lower cost and higher reliability.

|

🔧 Automate Your Sterilization Line Today

Automated basket handling can transform your operation. With a dependable automatic basket loader and unloader, you eliminate bottlenecks, reduce labor, and maintain high output—even in the most demanding environments.

📧 Email: lewis@micmachinery.com

🌐 Website: www.micbeveragemachine.com

📞 WhatsApp/Phone: 0086-13961211672

Ready to streamline your loading and unloading processes? Contact Jiangsu Mic Machinery and discover how our automatic loading and unloading machine solutions can optimize your production line.