Showing 1–9 of 8 results

MIC-B Vial Labeller(40-200 Bottles/min)

This device is suitable for circumferential or semi-circular labeling of various cylindrical objects that are unstable when standing. Widely used in industries such as cosmetics, food, medicine, daily chemical, electronics, toys, hardware, plastics, etc., it can achieve full week/half week labeling. Adopting horizontal conveying and horizontal labeling methods to increase stability and improve labeling efficiency. Optional color coding machines and inkjet printers can be used to print production batch numbers, production dates, and other information while labeling, achieving the integration of labeling and coding, reducing packaging processes, and improving production efficiency. Suitable for self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, QR code labels, transparent labels, etc. The equipment has high stability, good labeling effect, no bubbles, no wrinkles, and high labeling accuracy.

Learn more

MIC-BF Vial Labeling Machine (40-200 Bottles/min)

The MIC-BF high-speed horizontal self-adhesive labeling machine is suitable for circular or semi-circular labeling of various unstable cylindrical objects. Widely used in industries such as cosmetics, food, medicine, daily chemical, electronics, toys, hardware, plastics, etc., it can achieve full week/half week labeling. Adopting horizontal conveying and horizontal labeling methods to increase stability and improve labeling efficiency. Optional color coding machines and inkjet printers can be used to print production batch numbers, production dates, and other information while labeling, achieving the integration of labeling and coding, reducing packaging processes, and improving production efficiency. Suitable for self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, QR code labels, transparent labels, etc. The equipment has high stability, good labeling effect, no bubbles, no wrinkles, and high labeling accuracy.

Learn more

MIC-BFT Ampoule Labeling Machine (40-200 Bottles/min)

This device is suitable for circumferential or semi-circular labeling of various cylindrical objects that are unstable when standing. Widely used in industries such as cosmetics, food, medicine, daily chemical, electronics, toys, hardware, plastics, etc., it can achieve full week/half week labeling. Adopting horizontal conveying and horizontal labeling methods to increase stability and improve labeling efficiency. Optional color coding machines and inkjet printers can be used to print production batch numbers, production dates, and other information while labeling, achieving the integration of labeling and coding, reducing packaging processes, and improving production efficiency. Suitable for self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, QR code labels, transparent labels, etc. The equipment has high stability, good labeling effect, no bubbles, no wrinkles, and high labeling accuracy.

Learn more

MIC-A Small Bottle Labeling Machine(40-200 bottles/min)

The MIC-A vertical round bottle self-adhesive labeling machine is designed to achieve rational production goals. The labeling process is automated, with simple operation, fast production speed, and uniform, beautiful, and neat labeling positions; Suitable for circular container labeling in industries such as pharmaceuticals, chemicals, and food, it can be used for full circumference labeling and semi circumference labeling. Optional color matching with coding machine and inkjet printer, capable of printing production batch number, production date and other information while labeling. Realize the integration of labeling and coding, reduce packaging processes, and improve production efficiency.

Learn more

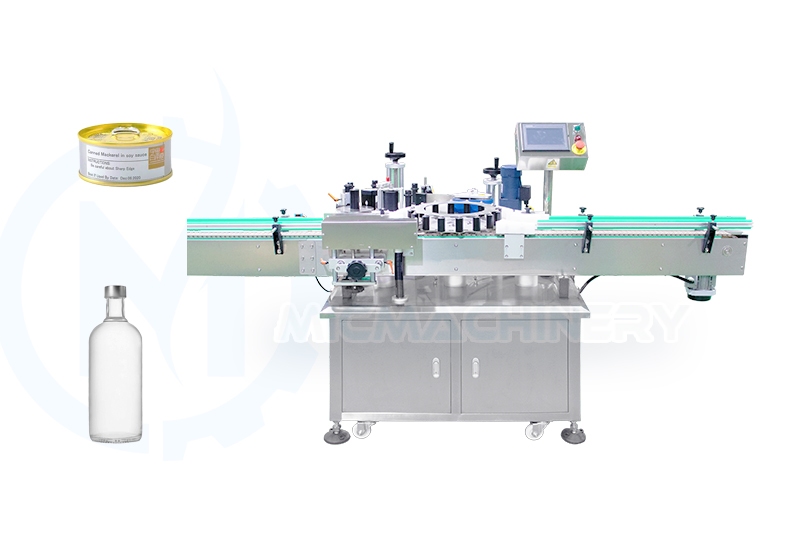

MIC-D Vial Labeler (40-200 Bottles/min)

The MIC-D single-sided self-adhesive labeling machine is suitable for single-sided or multi-faceted labeling of flat bottles, irregular bottles, round bottles, and square bottles in the daily chemical, home chemical, pharmaceutical, food, and other light industry industries. It can be equipped with a color matching coding machine and a spray coding machine, and can print production batch numbers, production dates, and other information while labeling. Realize the integration of labeling and coding, reduce packaging processes, and improve production efficiency. Suitable for self-adhesive labeling machines, self-adhesive films, electronic supervision codes, barcodes, QR code labels, transparent labels, etc. The equipment has high stability, good labeling effect, no bubbles, no wrinkles, and high labeling accuracy.

Learn more

MIC-DW Automatic Vial Labeling Machine(40-200 Bottles/min)

The MIC-DW type clamp positioning adhesive labeling machine is designed to achieve rational production goals. The labeling process is automated, with simple operation, fast production speed, and uniform, beautiful, and neat labeling positions; Suitable for circular container labeling in industries such as pharmaceuticals, chemicals, and food, it can be used for full circumference labeling and semi circumference labeling. Optional color matching with coding machine and inkjet printer, capable of printing production batch number, production date and other information while labeling. Realize the integration of labeling and coding, reduce packaging processes, and improve production efficiency.

Learn more

MIC-W Vial Label Applicator(40-200 Bottles/min)

The MIC-W star disk positioning adhesive labeling machine is designed to achieve rational production goals. The labeling process is automated, with simple operation, fast production speed, and uniform, beautiful, and neat labeling positions; Suitable for circular container labeling in industries such as pharmaceuticals, chemicals, and food, it can be used for full circumference labeling and semi circumference labeling. Optional color matching with coding machine and inkjet printer, capable of printing production batch number, production date and other information while labeling. Realize the integration of labeling and coding, reduce packaging processes, and improve production efficiency.

Learn more

Ampoule Sticker Labeling Machine(40-200 Bottles/min)

High speed vertical labeling machine is designed to achieve rational production goals. The labeling process is automated, with simple operation, fast production speed, and uniform, beautiful, and neat labeling positions; Suitable for circular container labeling in industries such as pharmaceuticals, chemicals, and food, it can be used for full circumference labeling and semi circumference labeling. Optional color matching with coding machine and inkjet printer, capable of printing production batch number, production date and other information while labeling. Realize the integration of labeling and coding, reduce packaging processes, and improve production efficiency.

Learn more