Showing 1–9 of 6 results

MIC-D Flat Surface Labeling Machine (40-200 Bottles/min)

The MIC-D single-sided self-adhesive labeling machine is suitable for single-sided or multi-faceted labeling of flat bottles, irregular bottles, round bottles, and square bottles in the daily chemical, home chemical, pharmaceutical, food, and other light industry industries. It can be equipped with a color matching coding machine and a spray coding machine, and can print production batch numbers, production dates, and other information while labeling. Realize the integration of labeling and coding, reduce packaging processes, and improve production efficiency. Suitable for self-adhesive labeling machines, self-adhesive films, electronic supervision codes, barcodes, QR code labels, transparent labels, etc. The equipment has high stability, good labeling effect, no bubbles, no wrinkles, and high labeling accuracy.

Learn more

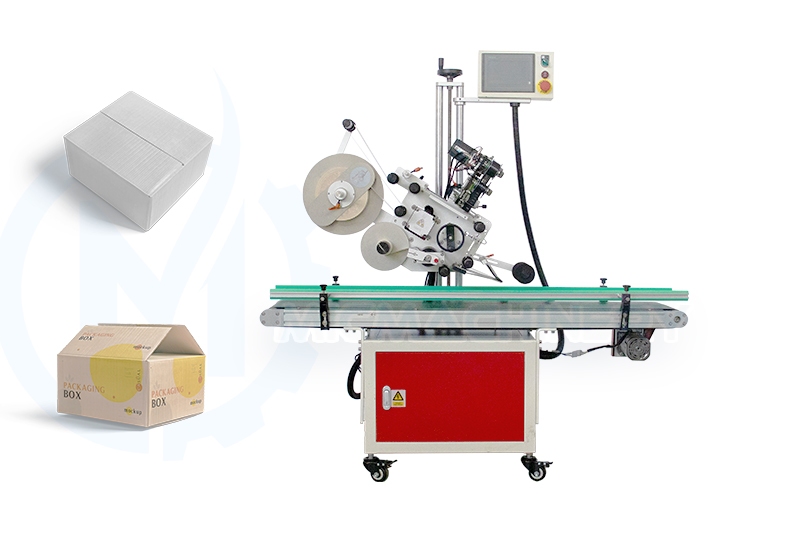

MIC-F Flat Surface Labeling Machine (40-200Bottles/min)

The MIC-F fully automatic pagination self-adhesive labeling machine can be used for stacking products of various materials, specifications, and shapes of cards, plastics, and paper, automatically dividing them into single sheets and labeling them. For example, plastic bags, paper, paper boxes, recharge cards, network cards, IP cards, 200 phone cards, 300 phone cards, and other items are automatically divided into sheets and then accurately labeled with self-adhesive labels. (Can be labeled with anti-counterfeiting labels, barcode labels, etc.). High labeling accuracy, no bubbles in the film; Equipped with automatic product recognition function, different labeling heads can be automatically activated according to different products.

Learn more

MIC-600 Automatic Flat Label Applicator

The MIC-600 Top and Bottom Label Applicator is a high-precision labeling machine designed for dual-side labeling. Ideal for flat bottles, boxes, and containers, it ensures fast, stable, and accurate label placement.

Learn more

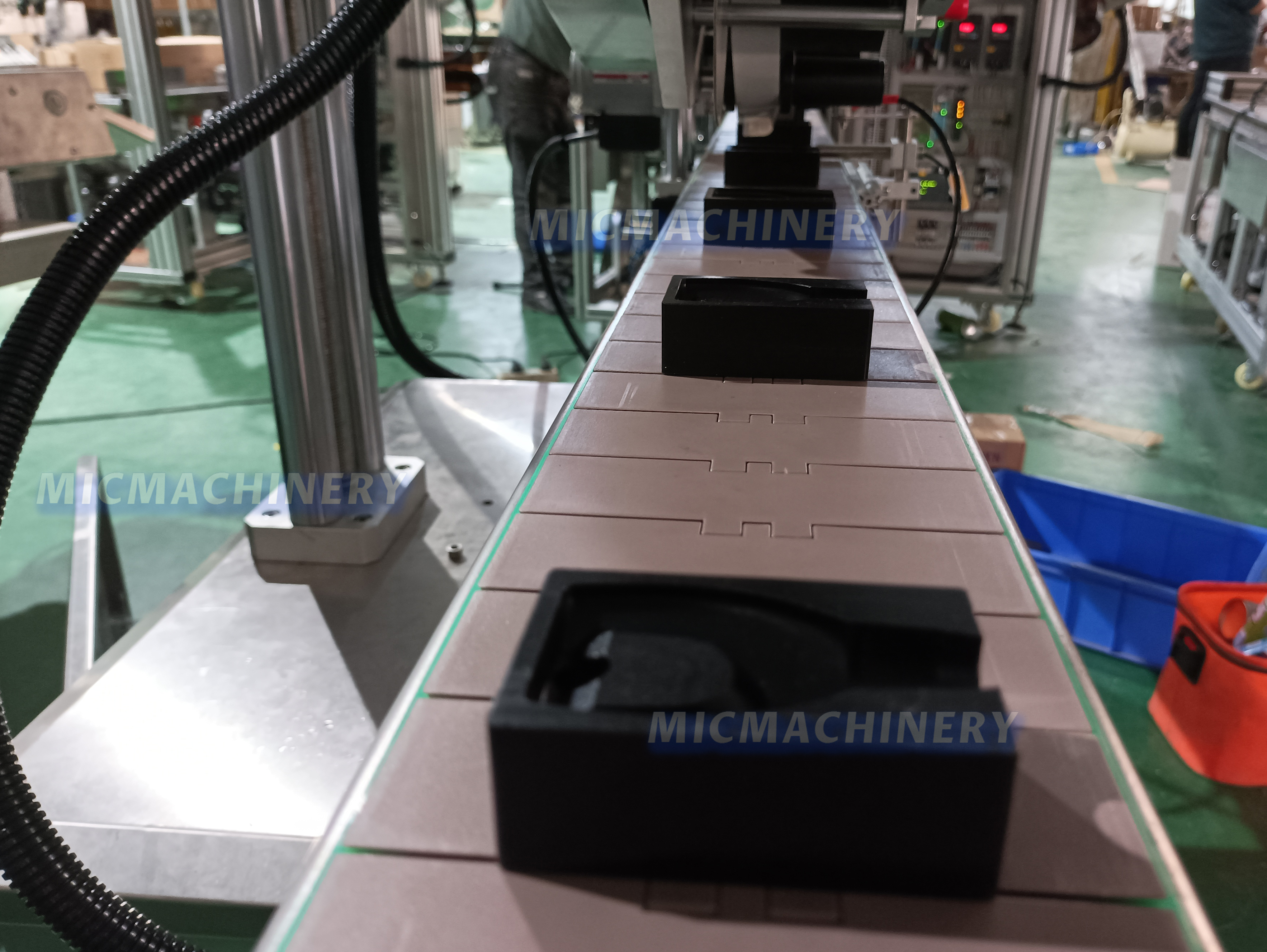

MIC-C Flat Labeling Machine (40-200Bottles/min)

The MIC-C cardboard sticker labeling machine is a new generation of series equipment. It is specially designed and manufactured according to the process and technical requirements of the automatic labeling machine. It can make the adhesive labels on the surface of the cardboard box flat and beautiful. The labeling process is stable and reliable, and the labeling position fully meets the ideal requirements.

The MIC-C cardboard sticker labeling machine is an electromechanical integrated product with a simple and comprehensive structure. This machine can automatically apply self-adhesive label paper flat on the cardboard box. In case of missing boxes, the control system of the machine can ensure that the label paper is not sent out, effectively preventing the waste of label paper. It can also adjust the production capacity infinitely according to the specifications and characteristics of the milk box and label paper. By using this labeling machine, it has strong adaptability to bottles and can attach satisfactory labels to bottles and paper boxes of various specifications and materials in industries such as food, medicine, and cosmetics.

Learn more

MIC-PM Automatic Flat Labeling Machine (40-200Bottles/min)

The MIC-PM surface single adhesive labeling machine is designed to achieve rational production goals. The labeling process is automated, with simple operation, fast production speed, and uniform, beautiful, and neat labeling positions; This device is mainly suitable for automatic labeling of express waybill products.

Learn more

MIC-P Flat Labeling Machine (40-200Bottles/min)

The MIC-P flat adhesive labeling machine is designed to achieve rational production goals. The labeling process is automated, with simple operation, fast production speed, and uniform, beautiful, and neat labeling positions; This equipment is mainly suitable for single side or flat automatic labeling of flat and square bottles in industries such as food and beverage, grain and oil, medicine, daily chemical, and chemical.

Learn more