Showing 1–9 of 1 results

Advanced Can Oiling Machine for Protective Tinplate Processing

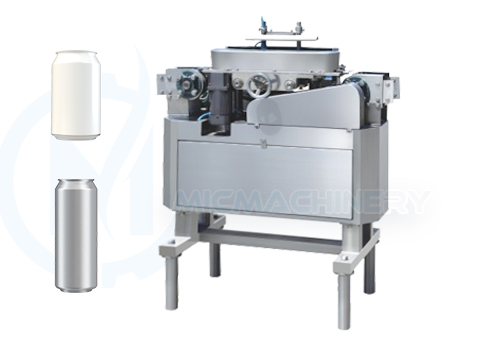

In the world of metal packaging, protecting the inner surface of cans is vital to preserve food quality, prevent corrosion, and comply with industry hygiene standards. At Jiangsu Mic Machinery, we specialize in high-efficiency solutions for the canning industry—including the precise and automated can oiling machine, engineered for accurate internal surface lubrication of tinplate cans.

Our oiling systems help improve can performance during sterilization, storage, and filling, making them an essential part of any food canning line.

✅ What Is a Can Oiling Machine?

|

A can oiling machine is a specialized device used to spray a fine layer of food-grade oil inside empty metal cans—particularly tinplate cans—before filling. The oil coating helps reduce internal friction, prevents oxidation, and minimizes interaction between the can and its contents. This step is especially important for cans used in high-temperature sterilization processes, where metal exposure could otherwise affect product taste or safety. |

⚙️ How Our Tinplate Can Oiling Machine Works

Our tinplate can oiling machine is built for seamless integration with high-speed canning lines. It uses precision nozzles to evenly distribute a controlled volume of oil or anti-rust agent inside each can as it passes through the machine.

Process overview:

1. Empty can infeed: Cans arrive via conveyor

2. Automatic positioning: Sensors detect each can and trigger nozzles

3. Internal spraying: A mist or jet of oil is applied to the inner wall

4. Optional air blowing: To ensure even distribution and avoid pooling

5. Exit: Cans continue downstream to rinsing or filling stations

All spray parameters—volume, pressure, duration—can be adjusted via a touchscreen HMI, ensuring consistent quality and low material waste.

🔩 Key Features of Jiangsu Mic Machinery Can Oiling Systems

|

Our can oiling machine is designed to support high-volume production, with features that enhance durability and control: • ✅ Stainless steel frame for hygiene and corrosion resistance • ✅ Multiple spray heads for round, oval, or irregular-shaped cans • ✅ Suitable for food-grade mineral oil or plant-based lubricants • ✅ Adjustable spray width and height for different can sizes • ✅ PLC control with real-time monitoring and fault detection • ✅ Easy maintenance and minimal downtime With flexible setup options and modular construction, our tinplate can oiling machine fits seamlessly into both new and existing lines. |

|

📐 Can Oiling Machine Technical Specifications

| Production Capacity | 0-400cans/min |

| Can Diameter | Φ52.5-105mm |

| Can Height | 75-133mm |

| Power | 0.5KW |

| Weight | 200KG |

| Dimensions | 1200*650*1200mm |

🏭 Application Scenarios

|

|

Jiangsu Mic Machinery’s oiling machines are ideal for: • 🥫 Canned vegetables • 🥩 Processed meats • 🐟 Canned fish or seafood • 🥣 Ready-to-eat meals in tinplate cans • 🍅 Tomato paste and acidic foods By using a can oiling machine, you ensure that each can is properly protected before filling—helping preserve both the can and its contents. |

🌐 Why Choose Jiangsu Mic Machinery?

|

As a trusted manufacturer with decades of experience, Jiangsu Mic Machinery provides fully integrated solutions for can processing lines. Our tinplate can oiling machine is developed with: • 📐 Customized engineering for your can sizes and production capacity • 🛠 Reliable international components with CE-compliant safety features • 🔧 Factory testing, installation, and global technical support • 📈 Proven efficiency in both food and non-food canning operations Whether you’re working with semi-automatic systems or fully automated lines, our equipment improves production speed and product safety. |

|

🚀 Upgrade Your Canning Line Today

If your operation involves tinplate packaging, an efficient can oiling machine is critical for long-term reliability and food safety. Let Jiangsu Mic Machinery provide the automation you need to boost output, reduce waste, and meet global quality standards.

📧 Email: lewis@micmachinery.com

🌐 Website: www.micbeveragemachine.com

📞 WhatsApp/Phone: 0086-13961211672

Contact us now to learn more about our tinplate can oiling machine models and discover how we can help you build a better canning system.