1. What is a Tea Beverage Production Line?

2. The Role of China in Tea Beverage Production

3. Core Processing Steps in Tea Drink Manufacturing

4. Different Types of Tea Beverages Processed

5. Equipment Used in Tea Beverage Production

6. Advantages of a Modern Tea Beverage Production Line

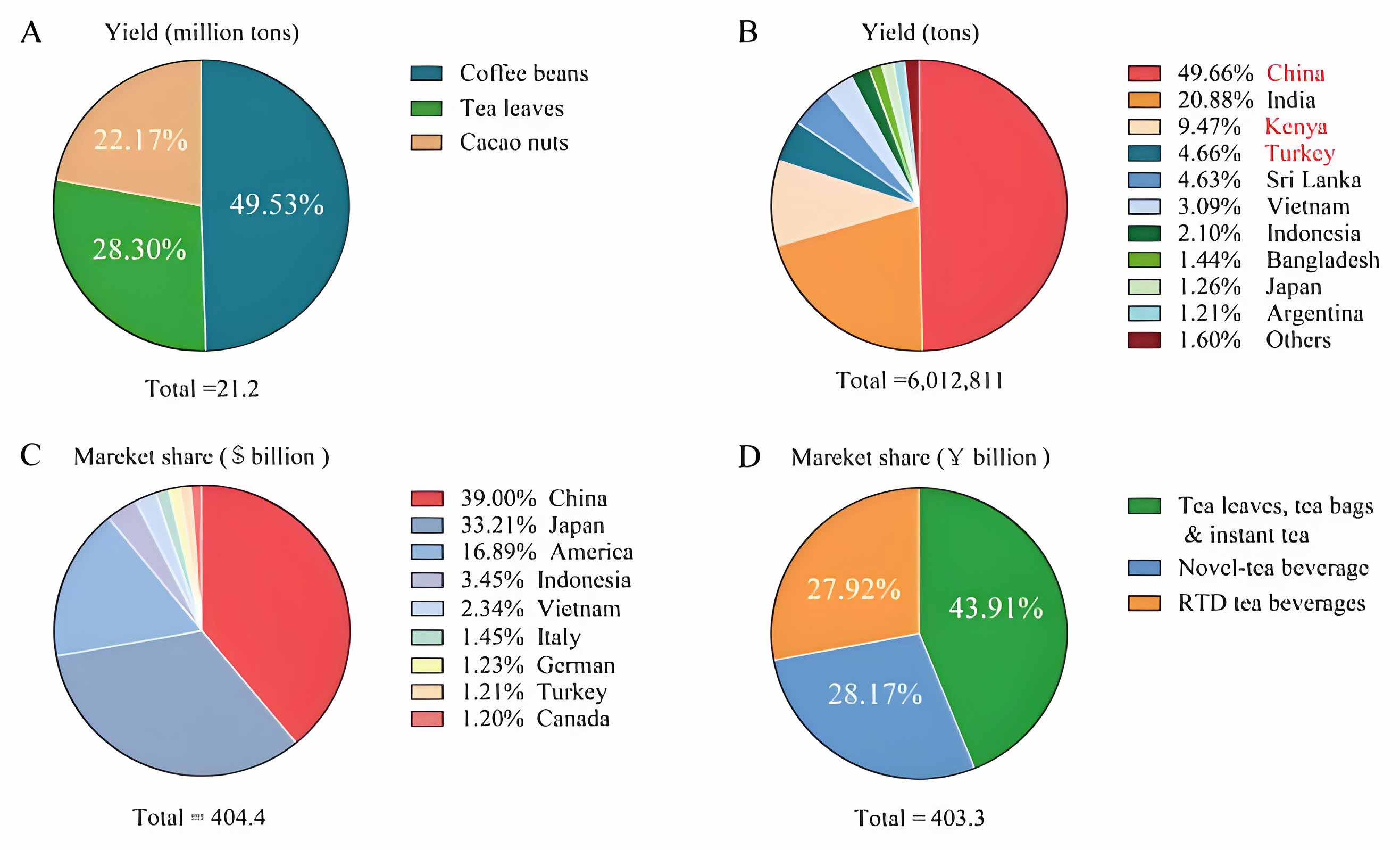

7. Market Outlook for Tea Beverages

Tea Beverage Production Line Solutions & Guide

Tea has become one of the most popular drinks worldwide, not only for its cultural value but also for its health benefits and refreshing taste. As consumer demand continues to grow for bottled tea, iced tea, herbal infusions, and ready-to-drink (RTD) tea products, the importance of having an efficient tea beverage production line has never been greater. This guide explains the key processes, available equipment, and advantages of investing in advanced tea production technology.

What is a Tea Beverage Production Line?

A tea beverage production line is a complete set of machinery designed to process tea leaves or extracts into packaged tea drinks. The line includes stages such as raw material extraction, blending, sterilization, filling, and packaging. Its automation ensures large-scale production with consistent flavor, hygiene, and efficiency. Whether producing green tea, black tea, oolong, or herbal drinks, manufacturers rely on these systems to meet market demand.

|

|

The Role of China in Tea Beverage Production

China has a long-standing tradition of tea cultivation and is also a global leader in modern tea processing technologies. A China tea beverage production line integrates advanced automation with the unique expertise of Chinese tea-making traditions. These lines are especially popular among international beverage companies because they combine cost-effectiveness, high productivity, and strong customization options. From green tea extractors to PET bottle filling systems, Chinese manufacturers provide complete solutions for tea drink factories worldwide.

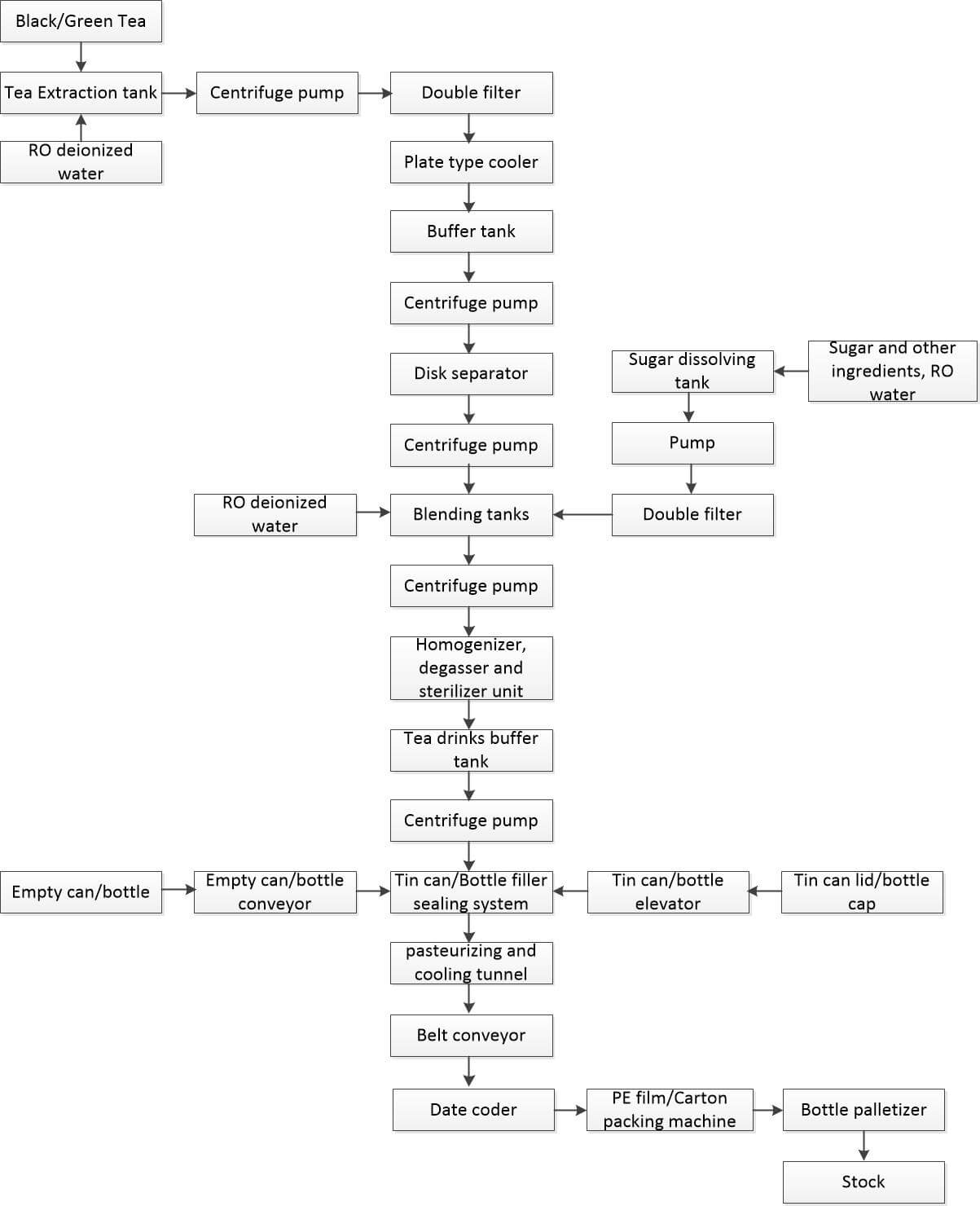

Core Processing Steps in Tea Drink Manufacturing

|

The production of RTD tea beverages involves several carefully controlled stages:

1. Raw Material Selection – Green tea, black tea, oolong, or herbal varieties are chosen.

2. Extraction and Brewing – Tea leaves are brewed at controlled temperatures to release flavor and bioactive compounds.

3. Filtration – Removes solids for a clear, smooth beverage.

4. Blending – Tea extract is mixed with sugar, flavors, fruit juices, or milk.

5. Homogenization – Ensures even texture and prevents separation.

6. Sterilization – Pasteurization or UHT extends shelf life while maintaining taste.

7. Packaging – Drinks are filled into bottles, cans, or cartons under hygienic conditions.

A fully automated tea drinks production line can handle all of these steps with minimal labor, ensuring consistency and high production capacity. |

Different Types of Tea Beverages Processed

A tea beverage production line can handle a wide range of products, including:

• Iced teas with fruit flavors like lemon or peach.

• Herbal teas infused with mint, ginger, or ginseng.

• Milk teas and bubble teas, which are gaining global popularity.

• Low-sugar or sugar-free tea beverages catering to health-conscious consumers.

|

|

|

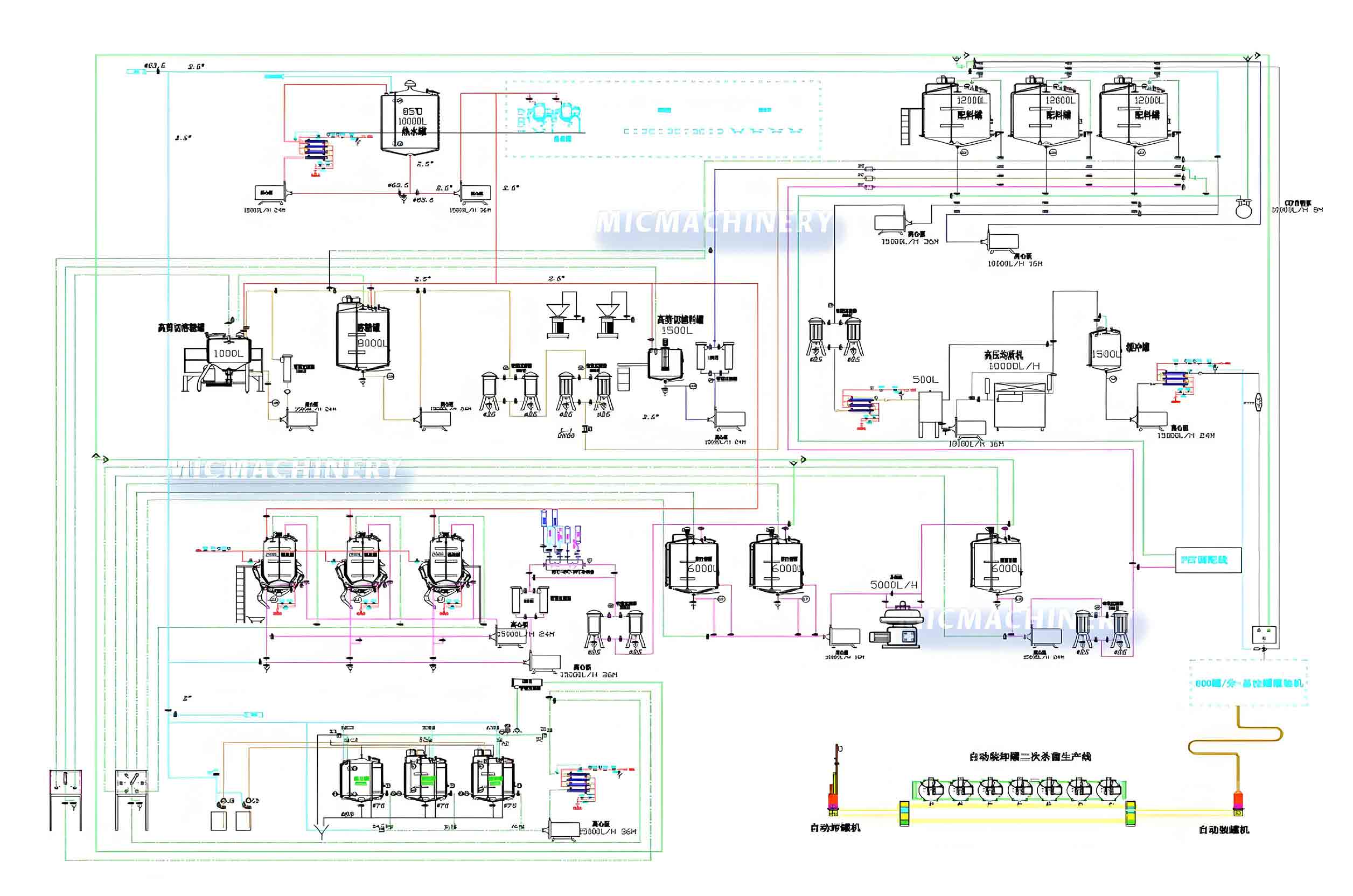

Equipment Used in Tea Beverage Production

A modern tea beverage production line consists of multiple machines working in sequence, including:

• Brewing and extraction tanks for controlled steeping.

• Filtration units to separate liquid from tea particles.

• Mixing and blending equipment for sugar, flavors, or milk tea formulations.

• Homogenizers to stabilize emulsions in milk-based teas.

• Sterilizers and pasteurizers for food safety.

• Aseptic filling machines for long shelf life without preservatives.

These components make the China tea beverage production line highly versatile, suitable for black tea, green tea, fruit-flavored teas, and herbal blends.

Advantages of a Modern Tea Beverage Production Line

Investing in an automated tea drinks production line brings several benefits to manufacturers:

• High Efficiency – Automated filling, capping, and labeling increase daily output.

• Quality Consistency – Each batch of tea beverage maintains uniform taste and clarity.

• Cost Reduction – Energy-efficient designs reduce waste and labor expenses.

• Flexibility – Ability to process multiple tea varieties in the same production facility.

|

|

|

Conclusion

The rise of RTD teas highlights the importance of advanced manufacturing systems like the tea beverage production line. Whether producing classic green tea, fruit-flavored drinks, or trendy milk teas, these lines guarantee efficiency, quality, and scalability. For companies aiming to meet global demand, choosing a China tea beverage production line provides reliable technology, competitive pricing, and flexible production capacity.

As consumer preferences continue to evolve, investing in a modern tea drinks production line is key to building a successful and sustainable tea beverage business.