1. What is the Process of Mango Processing?

2. What are the Processing Options for Mangoes?

3. What is the Cost of Mango Pulp Processing Plant?

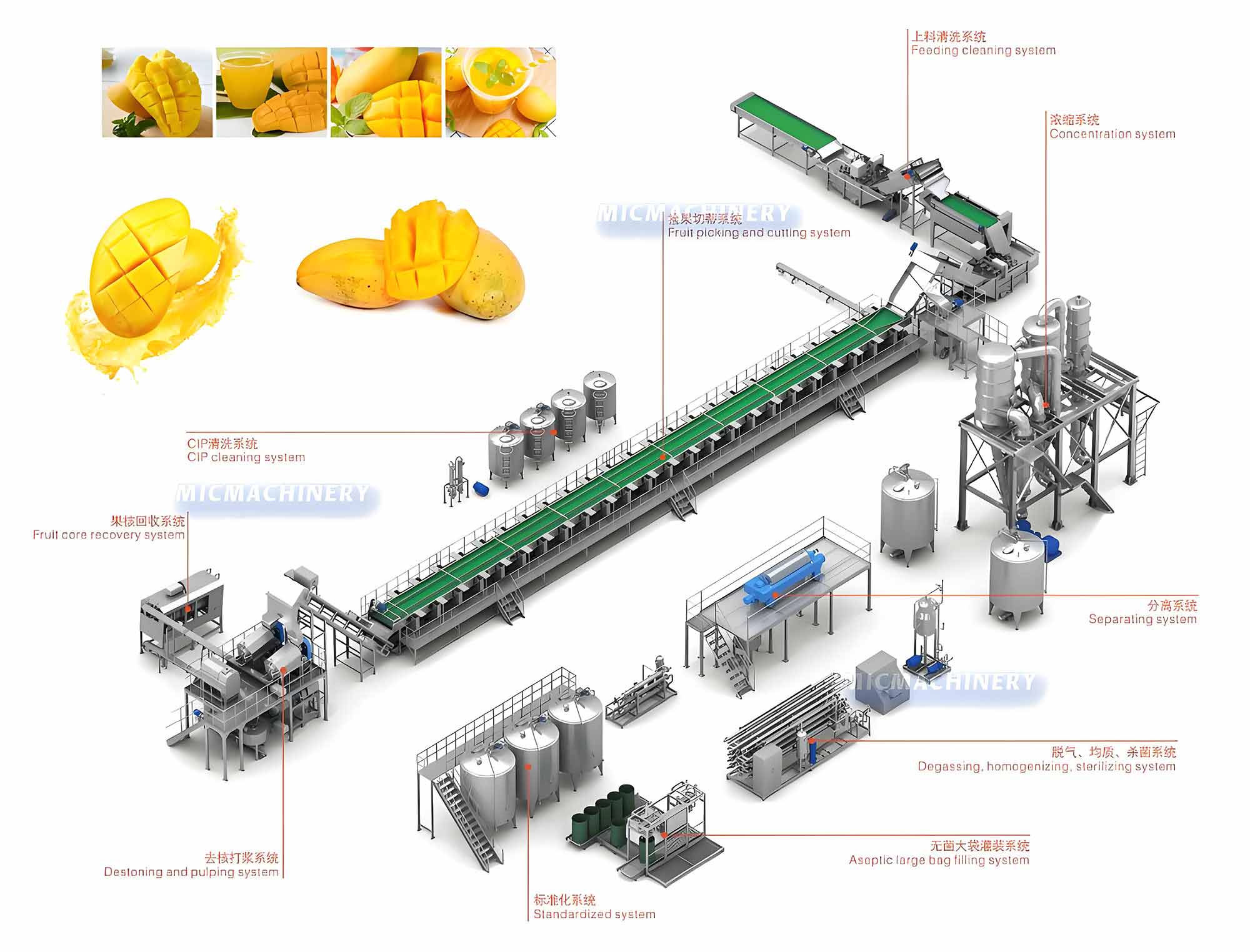

4. Equipment in a Mango Processing Line

5. Mango Processing System Features

6. Applications of Mango Processing Products

7. Advantages of Mango Processing Line

8. Global Demand and Market Trends

Complete Guide to Mango Processing Line

Mangoes are one of the most popular tropical fruits worldwide, enjoyed fresh or processed into juices, purees, concentrates, jams, and even dried snacks. To meet growing market demand, food manufacturers rely on advanced mango processing line systems that handle large-scale production with efficiency and quality assurance. This guide explores the full mango processing workflow, available processing options, equipment requirements, and the investment considerations for establishing a mango pulp processing facility.

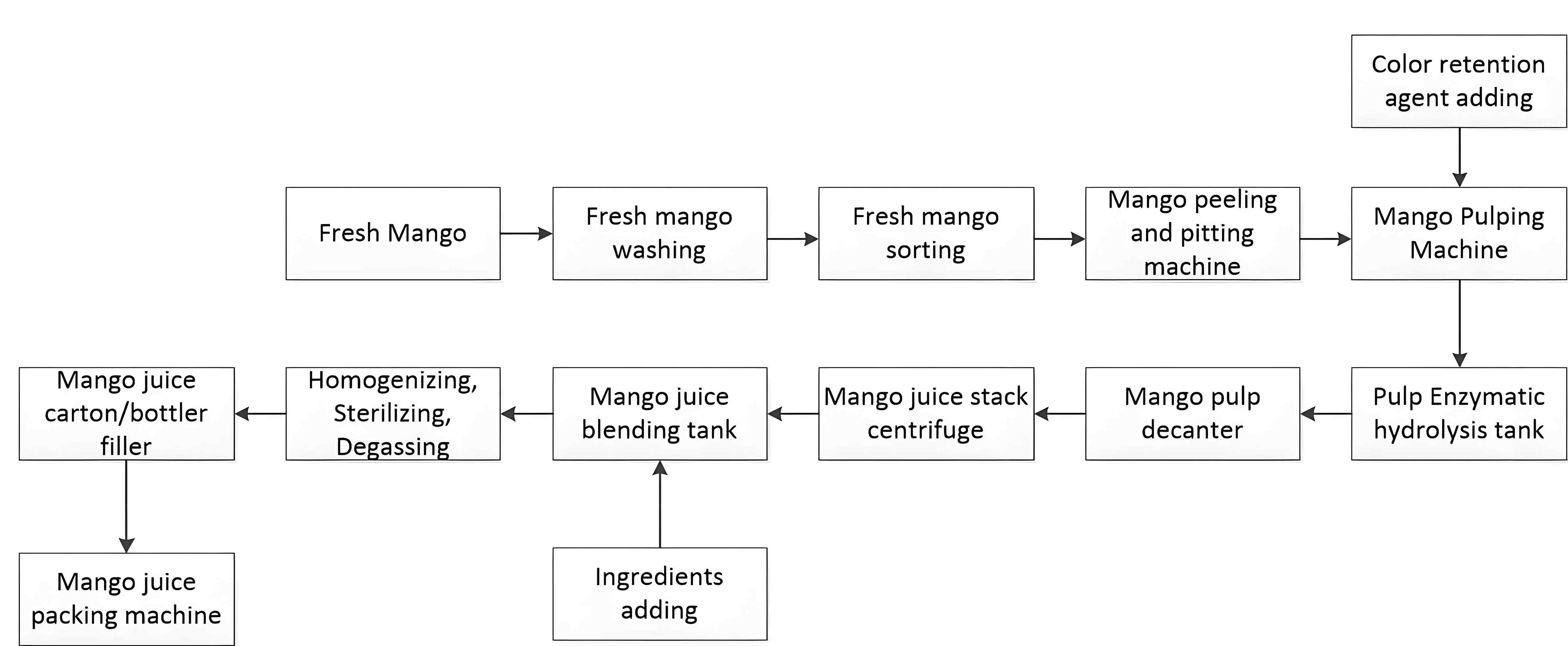

What is the Process of Mango Processing?

The process of mango processing involves several carefully coordinated stages designed to preserve flavor, nutrition, and safety. A mango processing line typically includes the following steps:

1. Raw Material Reception and Sorting

Fresh mangoes are received from farms and sorted to remove damaged, overripe, or underdeveloped fruits. Automated grading systems help maintain consistent quality.

2. Washing and Cleaning

Mangoes undergo thorough washing to remove dirt, pesticides, and residues. This step often uses bubble washing machines with circulating water and sanitizers.

3. Peeling and Destoning

Specialized mango processing machine and production line equipment is used to peel mangoes and remove seeds efficiently. Mechanical or enzymatic peeling

systems are employed depending on product requirements.

4. Pulping

Mango flesh is extracted and turned into pulp through pulping machines. This pulp can be used directly in beverages or as a base for further processing.

5. Refining and Filtering

The extracted pulp is refined to achieve smooth texture and remove fibers or impurities. Filtration systems ensure uniform consistency.

6. Pasteurization

Heat treatment is applied to kill harmful microorganisms and extend shelf life while preserving taste.

7. Concentration (Optional)

For mango puree concentrate or juice concentrate, water is partially removed through evaporation.

8. Packaging

Depending on the product, packaging options include aseptic bags, bottles, cans, or cartons. A mango juice production line may integrate filling and sealing machines for

high-speed operation.

9. Cold Storage & Distribution

Finished products are stored under controlled conditions to maintain quality until they reach consumers or manufacturers for secondary use.

What are the Processing Options for Mangoes?

Mangoes can be transformed into a wide range of commercial products through different mango processing machine and production line setups:

• Mango Juice: A complete mango juice production line can produce fresh juice, nectar, or blended beverages.

• Mango Pulp/Puree: A mango pulp processing line extracts and refines pulp for use in ice creams, yogurts, jams, and baby foods.

• Mango Concentrate: Concentrated puree or juice is produced for export and long-term storage.

• Canned Mango Products: Diced or sliced mangoes are canned in syrup or juice.

• Dried Mangoes: Dehydration removes moisture for long shelf life, creating a popular snack.

• Frozen Mango Products: IQF (Individually Quick Frozen) technology preserves diced mango chunks.

• Mango Jam, Chutney, and Sauces: Processed into condiments with sugar, spices, and preservatives.

Each processing option requires a slightly different mango processing line, with machines adapted to the intended final product.

What is the Cost of Mango Pulp Processing Plant?

|

The cost of setting up a mango pulp processing line varies widely, depending on capacity, level of automation, and production requirements. Factors include:

• Plant Capacity – A small-scale plant may process 500–1,000 kg/hour, while large-scale operations can handle up to 20,000 kg/hour. • Type of Equipment – Semi-automatic systems are more affordable, while fully automatic mango processing machine and production line setups require higher investment. • End Products – A mango juice production line may cost less compared to a diversified plant producing pulp, concentrate, and dried mangoes. • Installation and Utilities – Costs for water, electricity, steam, and cooling systems add to the investment. • Packaging System – Advanced aseptic packaging increases cost but extends product shelf life. |

|

On average, a medium-scale mango pulp processing line may cost anywhere between $100,000 and $500,000, while large industrial plants can exceed $1 million. Although initial investment is significant, mango processing plants offer high returns due to the global demand for mango-based products.

Equipment in a Mango Processing Line

A fully functional mango processing line integrates various machines that streamline operations from raw mango handling to final packaging. Essential equipment includes:

• Washing and grading machines

• Peeling and destoning machines

• Pulping and refining machines

• Pasteurizers and sterilizers

• Concentrators and evaporators

• Filling and packaging systems

• Cold storage and auxiliary systems (boilers, water treatment, etc.)

High-end mango processing machine and production line designs feature automation, energy-saving technology, and smart monitoring systems to maximize efficiency.

Mango Processing System Features

1. The treatment capacity ranges from 60 tons / day to 1500 tons / day.

2. It can handle fruits with similar characteristics.

3. Mango juice yield can be effectively improved by using mango efficient peeling machine.

4. Using belt type juicer to improve the juice extraction efficiency and juice yield of pineapple.

5. It can realize PLC control in the whole production process, save labor and facilitate production management.

6. Vacuum concentration at low temperature can retain flavor and nutrients to the maximum extent and save energy.

7. aseptic tube sterilization and aseptic barrel filling can produce high quality aseptic juice products.

8. Full automatic CIP cleaning ensures the food hygiene and safety requirements of the whole line equipment.

Technical parameters of mango fruit processing line:

| Raw materials | Fresh mango and pineapple |

| Products | Mango pineapple clear juice or turbid juice, NFC or concentrated juice |

| Capacity | 60 t / D – 1500 t / D |

| Juice yield | 50-75% |

| NFC solid content | 10~20Brix |

| Solid content of concentrated juice | 60~72Brix |

| Packaging | Sterile bag / roof bag / Tetra Pak / PET bottle |

Applications of Mango Processing Products

Products from a mango juice production line or mango pulp processing line are widely used in:

• Beverage industry (juices, smoothies, flavored water)

• Dairy products (yogurt, flavored milk, ice cream)

• Confectionery (candies, bakery fillings, syrups)

• Foodservice industry (sauces, chutneys, jams)

• Export markets where processed mango has longer shelf life than fresh fruit

This wide applicability makes mango processing an attractive investment opportunity for food manufacturers worldwide.

|

|

|

|

Advantages of Mango Processing Line

Investing in a mango processing line offers several advantages:

• Value Addition: Extends the shelf life of seasonal mangoes, reducing waste.

• High Profitability: Mango-based products are in strong global demand.

• Automation: A modern mango processing machine and production line reduces labor costs and increases efficiency.

• Versatility: Supports multiple products like juice, pulp, puree, and concentrates.

• Export Opportunities: Processed mango products are widely accepted in international markets.

Global Demand and Market Trends

The consumption of mango-based products is growing steadily worldwide. Health-conscious consumers are driving demand for natural juices, purees, and dried fruit snacks. With advanced mango processing line setups, manufacturers can export to North America, Europe, the Middle East, and Asia, ensuring a strong return on investment.

Additionally, governments in mango-producing countries like India, Thailand, and the Philippines are encouraging investments in fruit processing plants to boost exports and reduce post-harvest losses.

|

|

|

|

Conclusion

The mango processing line is a vital solution for transforming fresh mangoes into a wide range of profitable products such as juice, pulp, puree, jam, and dried slices. With the right mango processing machine and production line, industries can achieve efficiency, quality, and global competitiveness. While the cost of a mango pulp processing line varies depending on plant size and automation, the investment offers long-term profitability due to increasing international demand. For businesses seeking to enter the fruit processing sector, mango processing is one of the most promising opportunities.