1. Understanding the Tomato Processing Line

2. Equipment Used in the Carrot Processing Line

3. Methods of Processing Tomatoes

4. Advantages of an Integrated Tomato-Carrot Processing Facility

5. Market Insights and Sourcing from China

6. Future Trends in Tomato and Carrot Processing

Tomato & Carrot Processing Lines: Equipment and Methods

The global shift towards healthier diets and convenient food products has placed vegetables like tomatoes and carrots at the forefront of industrial food processing.

These crops are highly valued for their nutritional profile, versatility in recipes, and adaptability in different forms — from juices and purees to concentrated pastes and ready-to-eat vegetable blends.

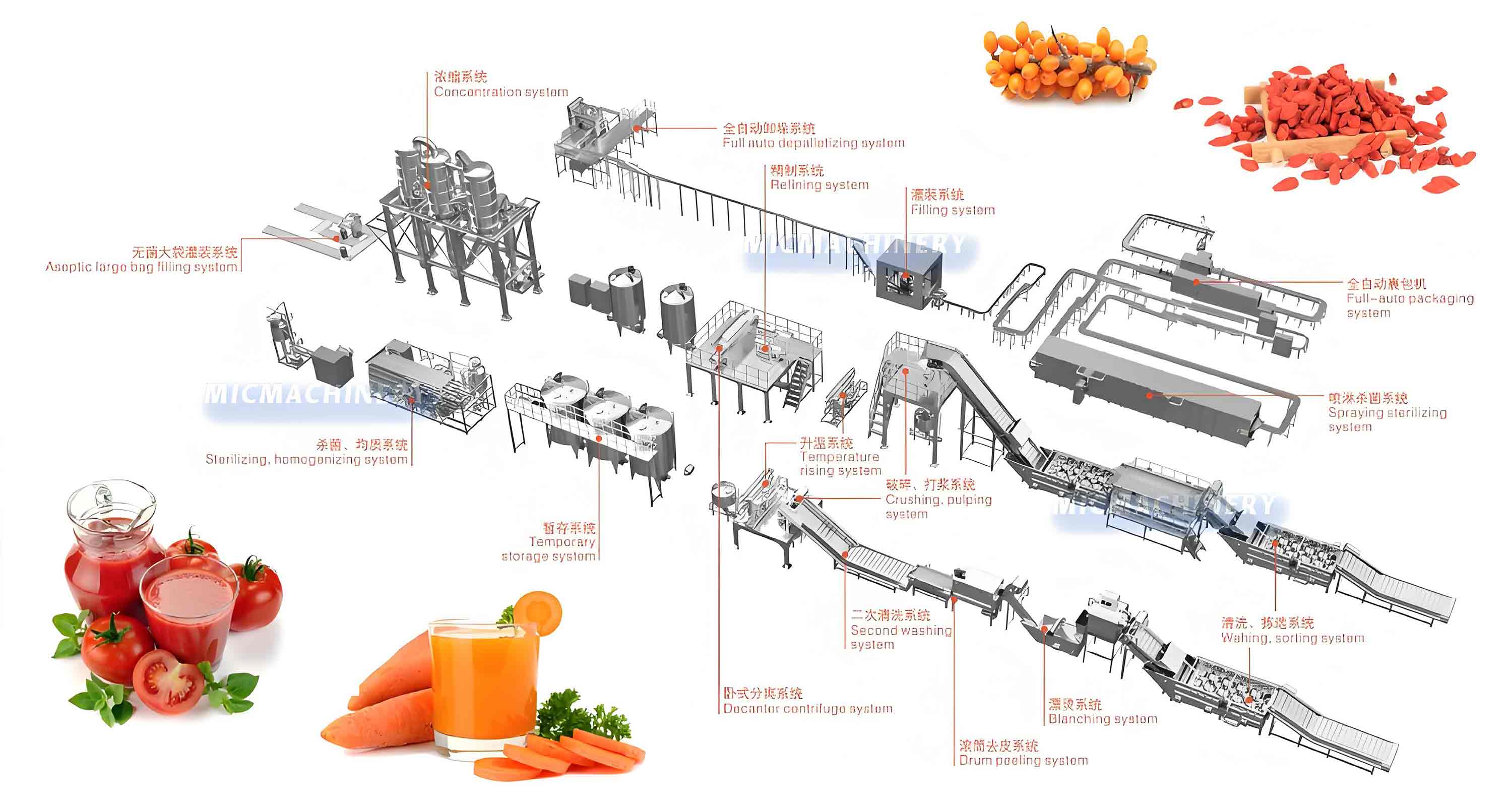

Modern tomato processing line and carrot processing line systems are engineered to convert freshly harvested produce into safe, high-quality finished goods while maintaining their natural flavors and nutrients. In the following sections, we will explore the fundamentals of tomato and carrot processing, the key machinery used, and the commercial aspects of investing in a tomato processing complete line or an industrial carrot juice processing line.

Understanding the Tomato Processing Line

A tomato processing line is a carefully designed arrangement of equipment that automates each stage of production. The process begins with raw tomato reception, where fresh produce is unloaded and sorted to remove damaged or unripe fruit.

Common products made from a tomato line:

• Tomato paste and puree for sauces or soups

• Ready-to-drink tomato juice

• Ketchup and specialty condiments

• Diced tomatoes for canned goods

• Concentrated tomato extracts for industrial use

A tomato processing complete line usually consists of washing units, sorting conveyors, crushers, pre-heaters, peelers, pulpers, evaporators, sterilizers, and filling machines. The configuration can be tailored to meet different production capacities — from small-scale artisanal factories to large-scale industrial plants producing hundreds of tons daily.

Equipment Used in the Carrot Processing Line

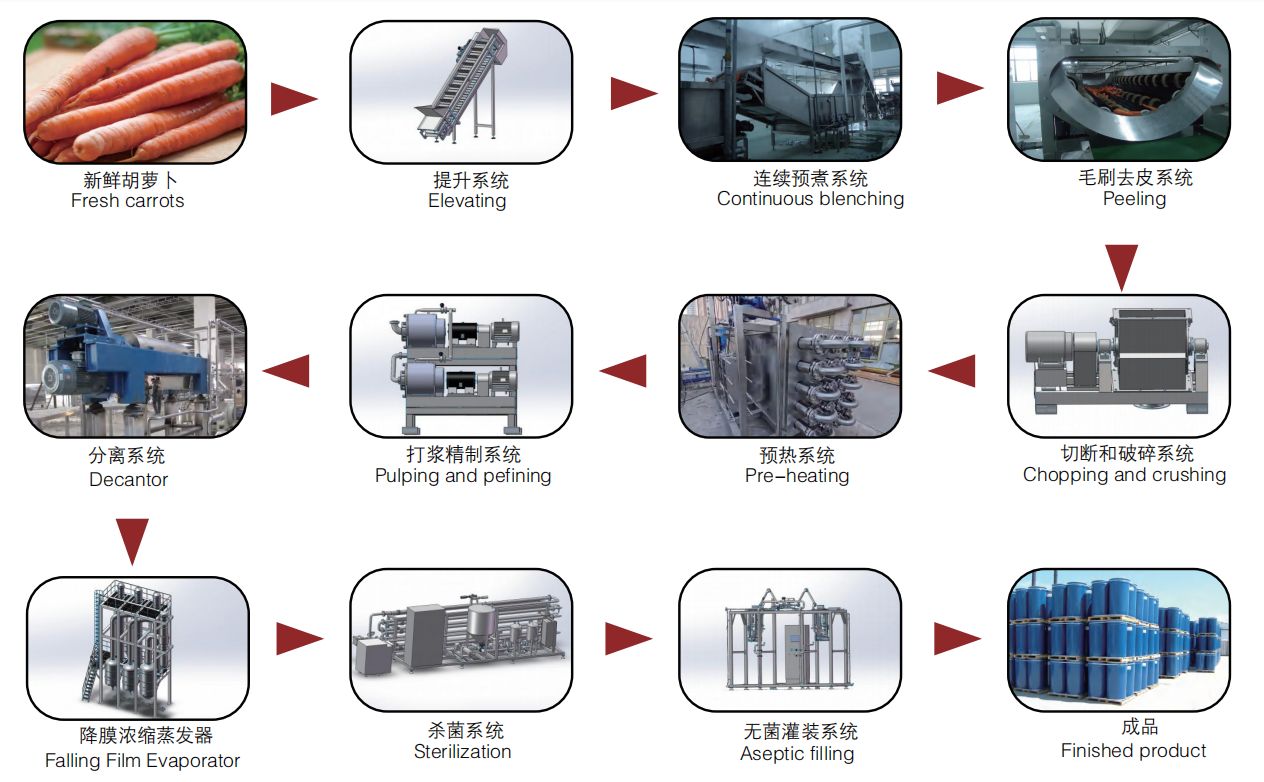

Carrot processing technology is designed to preserve the natural sweetness, vibrant color, and nutrient content of the vegetable. A carrot processing line may handle products like juices, purees, baby food, dehydrated carrot granules, and frozen carrot portions.

In a standard industrial carrot juice processing line, the following equipment is often used:

1. Reception Systems – Unload and feed carrots into the production line.

2. Washing Machines – Use rotating brushes and water sprays to clean dirt and soil.

3. Peeling Equipment – Remove the outer skin efficiently without damaging the core.

4. Sorting Conveyors – Manually or automatically remove defective carrots.

5. Cutting and Crushing Machines – Prepare raw carrots for juice extraction or cooking.

6. Pulping and Refining Units – Produce smooth juice or puree by separating fiber.

7. Sterilization Systems – Heat-treat the product to ensure microbiological safety.

8. Filling and Packaging Lines – Seal the product into bottles, pouches, or aseptic containers.

Trusted carrot processing line suppliers provide solutions for various scales of operation, and buyers can find both fully automated plants and smaller carrot processing line for sale models suitable for startups or regional producers.

Methods of Processing Tomatoes

Tomato processing varies according to the intended end product and quality requirements. The choice of method in a food processing line for tomato impacts taste, texture, and color stability.

Main tomato processing techniques:

• Hot Break Method – Immediately heats crushed tomatoes to around 90°C to deactivate pectin-degrading enzymes, yielding thicker pastes.

• Cold Break Method – Processes tomatoes at approximately 65°C, preserving a fresher flavor ideal for juice or light puree.

• Vacuum Concentration – Uses controlled low pressure to evaporate water while retaining color and aroma.

• Aseptic Processing – Sterilizes both the tomato product and the packaging separately to extend shelf life.

Advanced lines often integrate multiple techniques, enabling facilities to shift between different product types based on seasonal demand.

|

|

|

|

Advantages of an Integrated Tomato-Carrot Processing Facility

Running separate lines for tomatoes and carrots requires significant space, labor, and investment. By integrating production, manufacturers can operate a tomato processing complete line and an industrial carrot juice processing line in a shared facility.

Benefits include:

• Cost savings through shared washing, sorting, and filling systems

• Space efficiency by consolidating infrastructure

• Production flexibility to adapt to seasonal harvest schedules

• Energy efficiency with centralized steam and water systems

Such integration is especially valuable for facilities that supply both retail-ready products and bulk industrial ingredients.

Market Insights and Sourcing from China

China is recognized globally as a major producer of food processing machinery, with China carrot processing line options available for all production scales. The country’s manufacturers have built a strong reputation for offering durable stainless steel systems, competitive pricing, and customizable designs.

When sourcing from carrot processing line suppliers, important factors to evaluate include:

• Capacity – Match system size to expected production volume.

• Automation level – Choose between manual, semi-automatic, and fully automated options.

• After-sales support – Ensure access to spare parts and technical assistance.

• Compliance – Look for HACCP, ISO, and CE certification.

• Cost clarity – Compare offers, including carrot juice processing line price, to find the best value.

Many suppliers offer carrot juice processing line for sale with modular features, allowing easy upgrades as production expands.

|

|

|

|

Future Trends in Tomato and Carrot Processing

The vegetable processing sector is rapidly evolving, with innovations in automation, energy efficiency, and food safety. Future-ready food processing line for tomato and carrot systems may include:

• AI-based sorting for defect detection

• Continuous sterilization to reduce energy consumption

• Water recycling systems for sustainability

• Smart monitoring with IoT-enabled sensors for quality control

As consumer demand shifts toward cleaner labels and minimally processed foods, the design of both tomato processing complete line and carrot systems will adapt to handle organic, non-GMO, and specialty crop varieties.

Conclusion

Tomatoes and carrots remain two of the most important raw materials in the global food industry, and their processing requires precision, efficiency, and strict hygiene standards. Investing in a well-designed tomato processing complete line or an industrial carrot juice processing line allows producers to meet market demand for high-quality products year-round.

By working with reputable carrot processing line suppliers, considering equipment such as carrot processing line for sale, and evaluating carrot juice processing line price options, manufacturers can secure reliable, scalable systems that deliver long-term profitability. Whether producing for retail shelves or industrial supply chains, modern vegetable processing technology is the backbone of consistent product quality and operational success.