Showing 1–9 of 29 results

Hot Melt Vacuum Pan

The cheese melting pot is the main equipment for the processing of processed cheese. The main function of the cheese melting pot is to heat and emulsify the cheese raw materials in it. Generally, the temperature of heating cheese is 80-85℃, and the emulsification time of the processed cheese is about 5-8 minutes. Heating and emulsifying for a long time will cause excessive emulsification, and the product will have quality defects such as oil precipitationg. The butter melting pot is heated by two methods: sandwich water heating and directsteam injection.

Learn more

Multifunctional Extractor Tanks

This equipment is suitable for traditional Chinese medicine, food, and chemical industries, supporting processes such as decoction, reflux, percolation, aromatic oil extraction, and solvent recovery. The inverted-cone extractor tank allows easy residue discharge and efficient heating. Equipped with a CIP rotating spray ball, temperature port, explosion-proof sight glass, and quick-opening charging port, it ensures simple operation and meets cGMP standards. The inner tank is SUS304 stainless steel, with fully insulated jacket and SUS304 outer finish. Accessories include defoamer, filter, cooler, oil-water separator, and cylinder control console.

Learn more

Single-effect External Circulation Vacuum Concentrator

The equipment is applicable for the concentration and recovery of industrial organic solvent (such as alcohol) of traditional Chinese medicine, western medicine, glucose, starch sugar, oral liquid, chemical industry, food, monosodium glutamate and dairy products. lt can be used in the low temperature vacuum concentration of heat sensitive substances with srnall batches and large varieties.

Learn more

Double Effect Energy Saving Concentrator

The concentrator is applicable for concentration of liquid materials for traditional Chinese medicine, western medicines, glucose, starch, monosodium lutamate, dairy foods and chemical industry, especially ideal for low temperature vacuum concentration of heat sensitive substances.

Learn more

Pressure Spray Drying Tower

The pressure spray drying tower is a high-efficiency drying system widely used in the food, pharmaceutical, and chemical industries. It works by atomizing liquid materials through a high-pressure nozzle into fine droplets, which are instantly dried by hot air in the tower, producing uniform, high-quality powder. This method ensures rapid moisture removal, excellent solubility, and stable product quality, making it ideal for heat-sensitive materials.

Learn more

Vacuum Pressure Reducing Concentration Tank

The device mainly includes concentration can, condenser, gas-liquid separator, cooler and liquid receiving barrel. The concentration can is of clip-sleeve structure, the condenser is of row-pipe type, the cooler is of coiled type. The device is suitable for the concentration of the material liquid in such industries as pharmacy, food and chemistry, etc., and serves for the recycle of alcohol, simple returning distillation. The adoption of pressure reducing condensation and scrapper to wall protects the efective components of heat sensitive material. The contact part of the concentrator and the material is made with the stainless steel, resistant to corrosion and meeting the standard of the GMP.

Learn more

Ball Type Concentrating Tank

The roundness concentration tank, consisting of main body, condensator, gas-liquid separator and liquid receiving, barrel, serves to concentrate distil the material liquid and reclaim organic menstruum in the pharmacy, foodstuff and chemistry. The concentration under reduced pressure brings short time of concentration and prevent the destruction of the effective content in the thermat sensitive material.The fact that the part in contact with the material is made with stainless steel brings qualified anti-corrosion performance, meeting with the GMP standard.

Learn more

Multifunctional Alcohol Recovery Concentrator

This equipment is suitable for concentrating traditional Chinese medicine and alcohol precipitation solutions and recovering alcohol.

Learn more

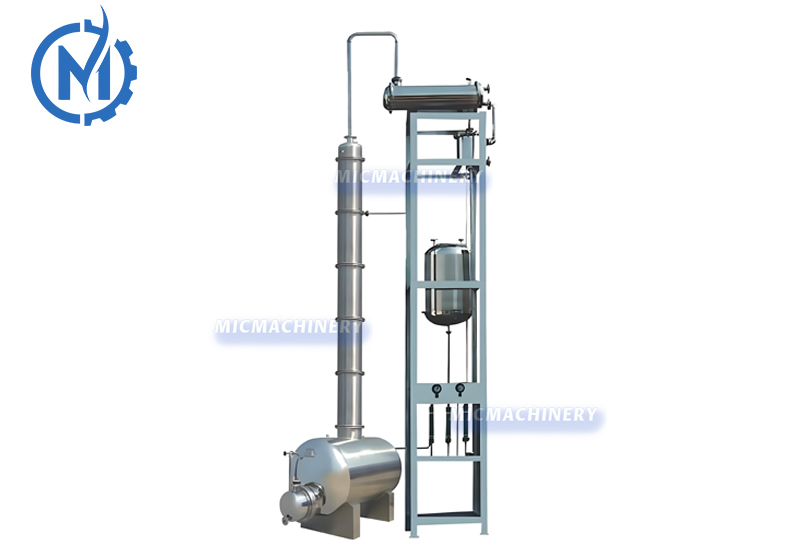

Alcohol Recovery Tower

This equipment is suitable for the percolation operation of traditional Chinese medicine, plant, animal, food, chemical and other industries. In addition to frankincense,rosin, aloe and other non-tissue medicinal materials due to solvent softening into a group, will block the pores so that the solvent can not evenly through the medicinal materials, and should not be used for percolation, other medicinal materials can be extracted by this method.

Learn more