1. What is a Plant Protein Drinks Processing Line?

2. Soy Milk and Its Industrial Processing

3. Oat Milk: The Rising Star in Plant Protein Drinks

4. Core Equipment in Plant Protein Drinks Processing

5. Step-by-Step Workflow in Plant Protein Drink Production

6. Cost and Investment Potential

7. Market Trends and Global Demand

Plant Protein Drinks Processing Line: From Soy to Oat

The global beverage industry is experiencing a significant shift toward plant-based protein drinks, driven by health-conscious consumers, sustainability concerns, and innovations in food processing. Beverages such as soy milk and oat milk are at the forefront of this trend, offering nutritious, dairy-free alternatives with growing worldwide demand.

At the heart of this transformation is the plant protein drinks processing line, an integrated system that converts raw soybeans, oats, and other plant sources into ready-to-drink beverages. With the help of advanced automation, these processing lines ensure efficiency, product safety, and consistent quality while allowing manufacturers to diversify their product range.

What is a Plant Protein Drinks Processing Line?

|

A plant protein drinks processing line is a specialized production system designed for large-scale manufacturing of plant-based beverages. Unlike traditional dairy processing, these lines are tailored to handle legumes, grains, and seeds, ensuring that proteins, starches, and fibers are processed into stable, nutritious drinks.

Key features include: • Versatility – Capable of producing soy milk, oat milk, almond milk, and other plant-based drinks. • Efficiency – Automated systems reduce waste and labor while increasing throughput. • Nutritional Retention – Gentle heat treatments and homogenization preserve natural nutrients. • Hygiene – Designed with stainless steel and CIP (clean-in-place) systems to meet global food safety standards. |

|

With rising consumer demand for sustainable nutrition, the plant protein drinks processing line has become an essential investment for beverage manufacturers worldwide.

Soy Milk and Its Industrial Processing

The soy milk production line is one of the most established systems in this category. Soy milk is valued for its high protein content, digestibility, and versatility in both sweetened and unsweetened forms.

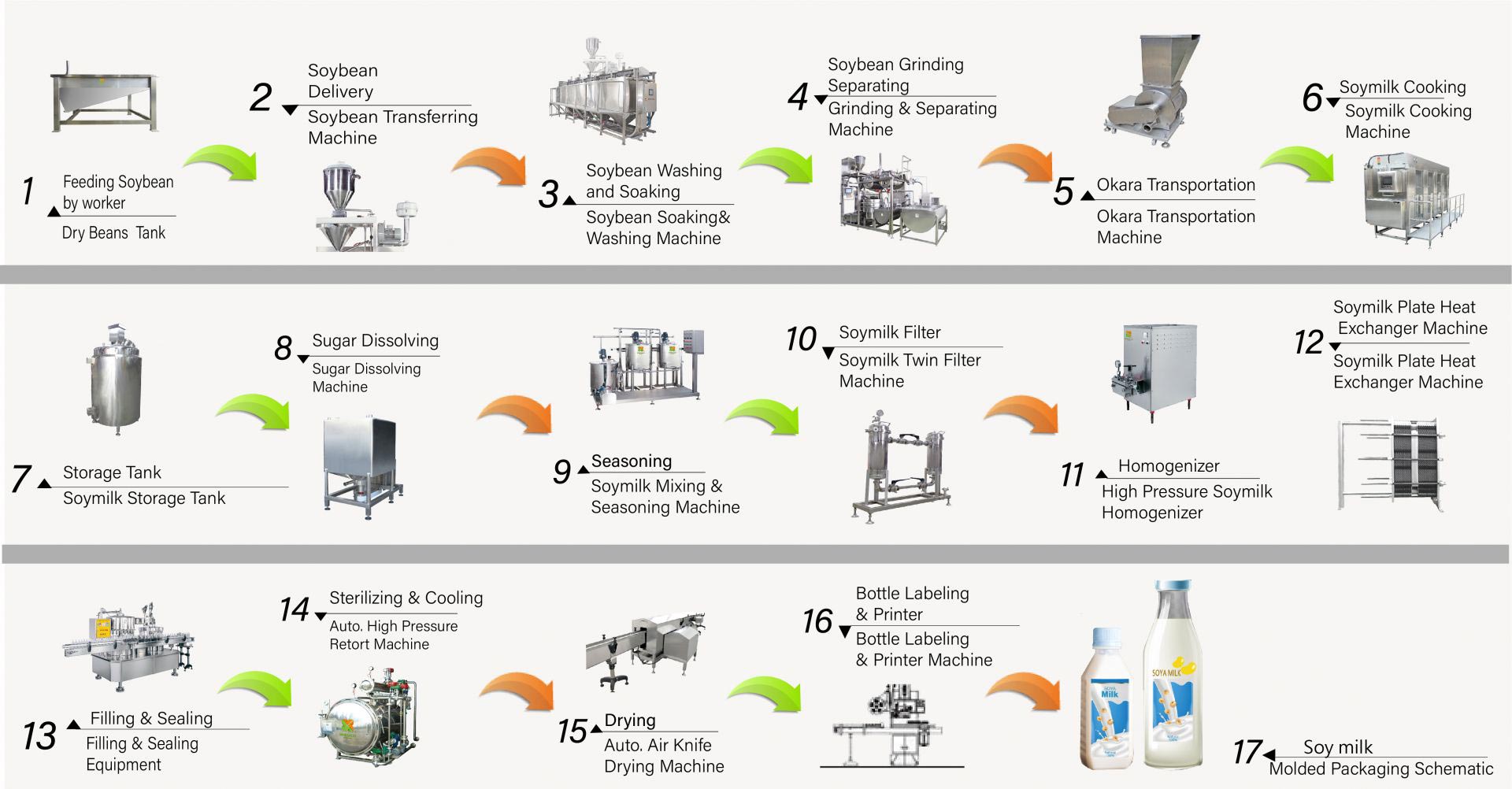

Processing Steps in a Soy Milk Production Line:

1. Cleaning & Soaking – Soybeans are cleaned and soaked for 6–12 hours to soften.

2. Grinding & Slurrying – Beans are ground with water to create a protein-rich slurry.

3. Heating & Enzyme Deactivation – Heat treatment removes anti-nutritional factors like trypsin inhibitors.

4. Filtration & Extraction – Fiber is removed, leaving smooth soy milk base.

5. Homogenization – Creates a stable, creamy texture.

6. Sterilization – Pasteurization or UHT (Ultra-High Temperature) processing extends shelf life.

7. Packaging – Aseptic filling into cartons, bottles, or pouches.

The soy milk production line not only ensures consistency but also allows producers to diversify into flavored soy milk, soy-based yogurts, and cooking ingredients.

Oat Milk: The Rising Star in Plant Protein Drinks

In recent years, oat milk has grown from niche to mainstream, largely due to its smooth texture, mild flavor, and sustainability benefits. The oat milk production line is specifically designed to process oats into dairy-free milk alternatives.

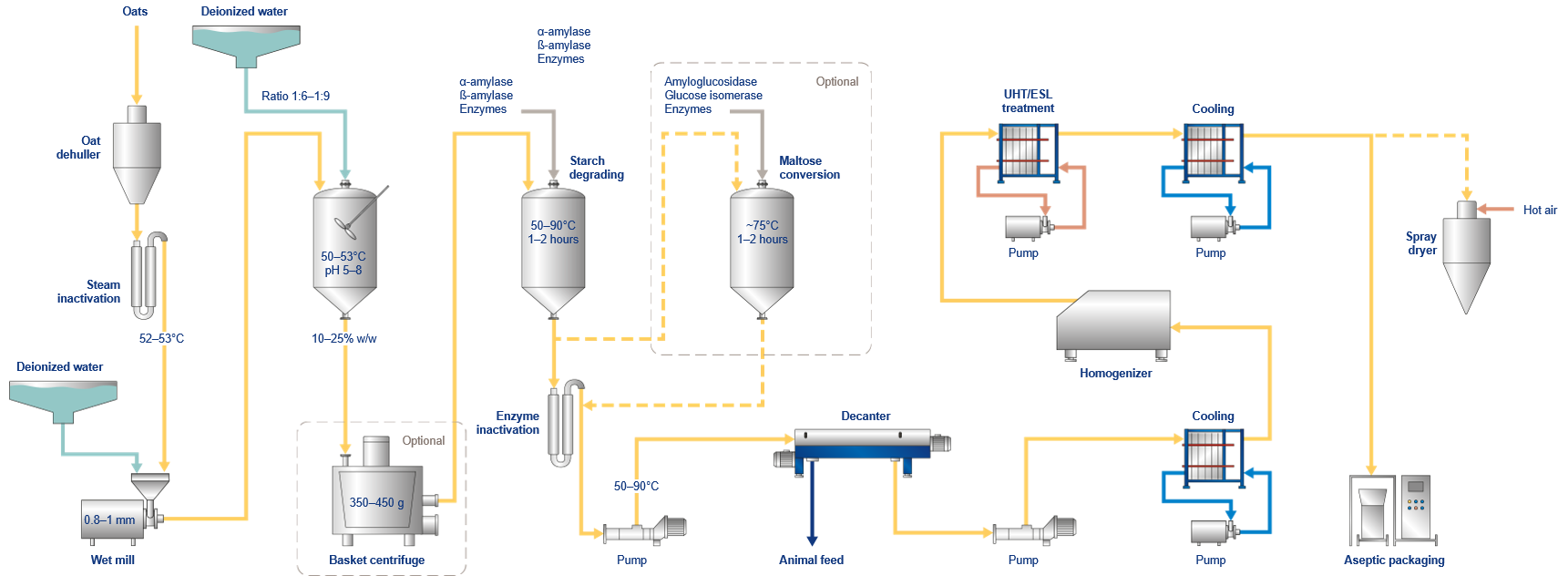

Processing Steps in an Oat Milk Production Line:

1. Cleaning & Sorting – Removal of husks, impurities, and broken grains.

2. Soaking & Milling – Oats are softened and milled into slurry.

3. Enzymatic Treatment – Starch is broken down into natural sugars for improved sweetness and digestibility.

4. Filtration & Separation – Insoluble fiber is removed to achieve smooth consistency.

5. Homogenization – Enhances texture and prevents separation.

6. Pasteurization or UHT Treatment – Ensures food safety and longer shelf life.

7. Packaging – Sealed aseptically for storage and distribution.

The oat milk production line has become essential for companies targeting lactose-intolerant, vegan, and eco-conscious consumers. Its rising demand makes it one of the most profitable plant protein beverages today.

Core Equipment in Plant Protein Drinks Processing

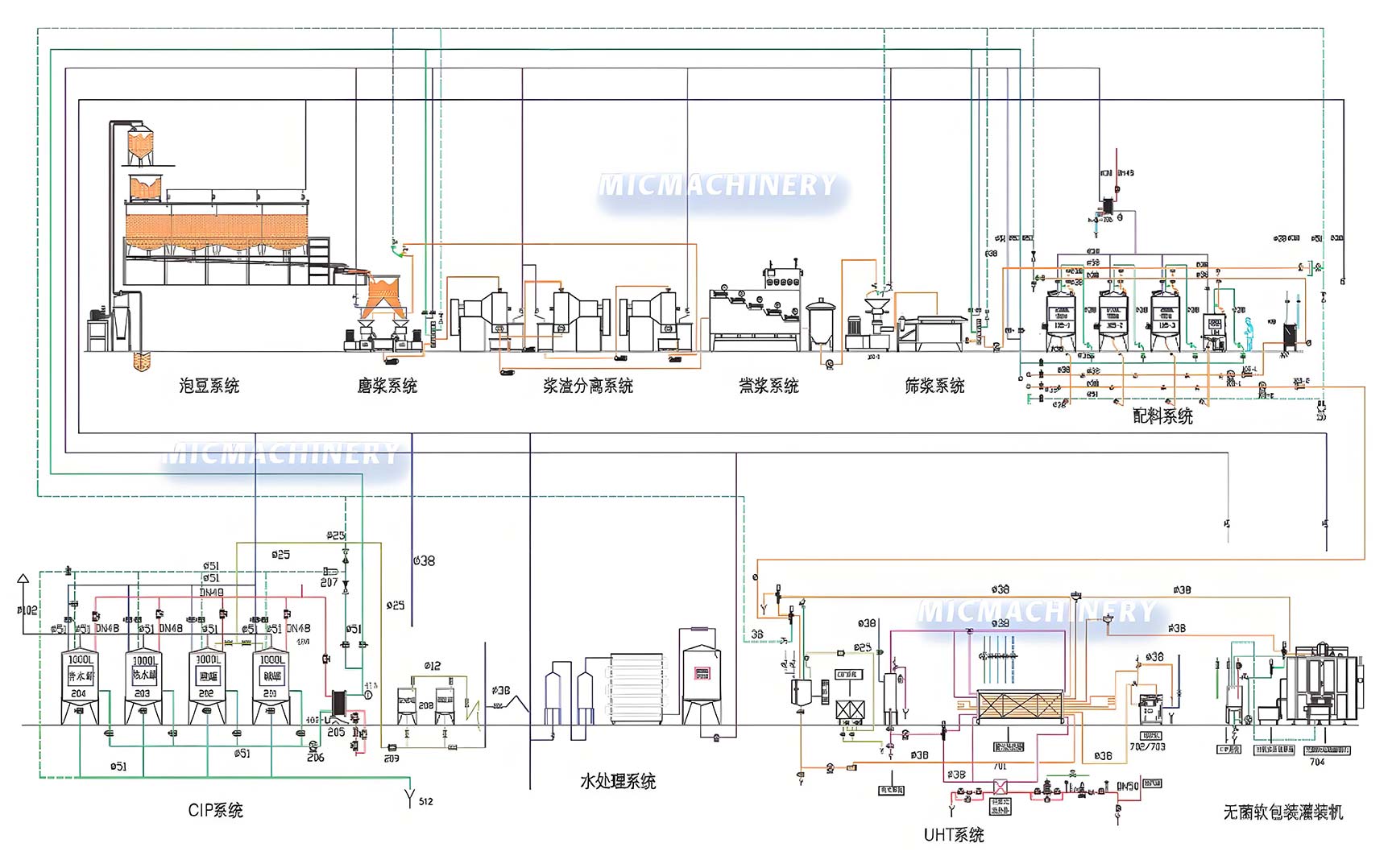

Both the soy milk production line and oat milk production line rely on advanced machinery to maintain efficiency and product quality. A typical plant protein drinks processing line includes:

• Raw Material Handling Systems – For cleaning and soaking soybeans or oats.

• Milling and Grinding Units – Convert raw ingredients into slurry.

• Extraction Systems – Separate proteins and nutrients from fibers.

• Homogenizers – Improve mouthfeel and stability.

• Heat Treatment Equipment – Pasteurizers and sterilizers for food safety.

• Mixing & Fortification Units – Add flavors, vitamins, or minerals.

• Filling & Packaging Machines – Aseptic systems for cartons, bottles, or pouches.

These machines are often modular, allowing factories to expand production capacity or switch between soy milk, oat milk, and other plant-based drinks.

|

|

|

|

Step-by-Step Workflow in Plant Protein Drink Production

Here’s how a complete plant protein drinks processing line works:

1. Raw Material Reception – Soybeans or oats are transported to the factory.

2. Cleaning & Sorting – Removal of dirt, stones, and impurities.

3. Soaking/Conditioning – Hydration improves grinding and extraction.

4. Grinding & Extraction – Release of proteins and nutrients into slurry.

5. Heating/Enzyme Treatment – Improves digestibility and taste.

6. Filtration – Removes insoluble residues for a smoother drink.

7. Homogenization – Prevents separation and enhances texture.

8. Pasteurization/UHT – Ensures microbiological safety.

9. Flavoring & Fortification – Optional addition of cocoa, vanilla, calcium, or vitamins.

10. Packaging & Distribution – Ready-to-drink beverages are sealed and shipped.

This standardized process ensures every batch meets quality standards and retains nutritional integrity.

Cost and Investment Potential

|

Investing in a plant protein drinks processing line varies depending on capacity, automation level, and customization.

• Small-scale lines: Suitable for startups, cost-effective but limited output. • Medium-scale lines: Ideal for regional markets, offering balance between cost and capacity. • Large-scale lines: Designed for international distribution with fully automated systems.

The cost of a soy milk production line or oat milk production line may range from a few hundred thousand to several million USD, depending on specifications. However, with the growing demand for plant protein beverages, return on investment is strong, particularly when paired with innovation in flavors and sustainable packaging. |

Market Trends and Global Demand

• Health and Wellness – Increasing focus on protein-rich, lactose-free drinks.

• Sustainability – Plant-based beverages have a lower carbon footprint than dairy.

• Customization – Fortified plant protein drinks with vitamins, minerals, and functional ingredients.

• Innovation – Flavored soy milk, barista oat milk, and hybrid drinks are becoming popular.

Global consumption of soy and oat milk continues to rise, creating profitable opportunities for companies investing in advanced plant protein drinks processing lines.

|

|

|

|

Conclusion

The plant protein drinks processing line represents the future of beverage manufacturing. With growing consumer demand for nutritious, dairy-free, and sustainable alternatives, investing in this technology provides long-term benefits.

Whether through a soy milk production line that delivers high-protein beverages or an oat milk production line that creates smooth, allergen-friendly drinks, manufacturers can meet evolving market needs. By adopting advanced equipment, streamlined workflows, and innovation in flavors and packaging, businesses can secure a strong position in the competitive plant-based beverage industry.