1. How Are Citrus Fruits Processed?

2. The Orange Juice Production Line in Focus

3. Essential Equipment in Citrus Processing Facilities

4. Choosing the Right Manufacturers and Suppliers

5. Beyond Orange Juice: Multi-Citrus Capability

6. Sustainability in Citrus Processing

Citrus Fruit Processing Line: Juice Production & Equipment

Citrus fruits — such as oranges, lemons, limes, and grapefruits — are some of the most important raw materials in the global food and beverage industry. They are not only rich in vitamin C, antioxidants, and essential oils, but also serve as the foundation for countless juices, concentrates, and flavor additives.

To transform these perishable fruits into safe, long-lasting, and flavorful products, manufacturers rely on an advanced citrus processing line. These systems are specifically engineered to maintain the fruits’ natural qualities while achieving maximum production efficiency. Whether producing fresh bottled juice or concentrated syrup for international markets, the right citrus processing machine and production line is a crucial investment for success.

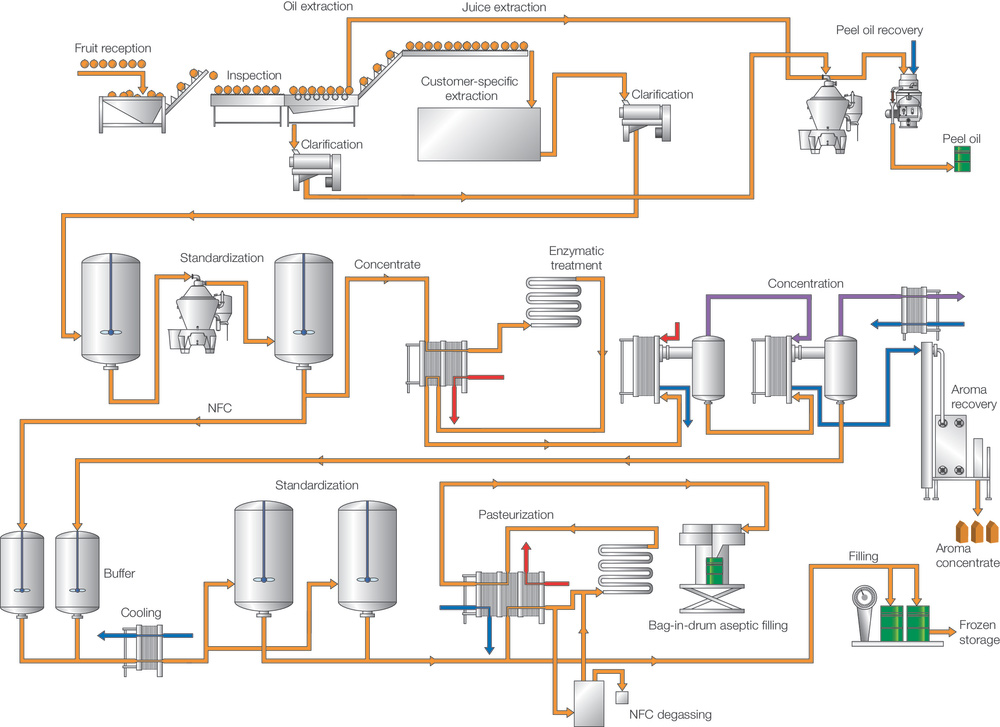

How Are Citrus Fruits Processed?

Processing citrus fruits involves a sequence of carefully monitored steps designed to preserve flavor and nutritional value while ensuring food safety.

A standard citrus processing machine and production line typically includes:

1. Reception and Inspection – Freshly harvested citrus is received from farms, visually inspected, and weighed. Any fruit showing signs of damage, mold, or decay is removed.

2. Washing and Sanitizing – Rotary washers and spray systems clean the surface of the fruit to remove dirt, pesticides, and debris. Sanitizing agents help reduce microbial load.

3. Grading and Sorting – Fruits are graded by size, color, and ripeness to ensure uniform juice quality.

4. Juice Extraction – Specialized extractors press the fruit to obtain juice without damaging the peel oil glands excessively.

5. Oil Recovery – For products like essential oils or flavoring agents, the peel oil is collected during the extraction process.

6. Filtration and Clarification – Removes seeds, pulp, and any residual solids depending on product requirements.

7. Pasteurization – Heat treatment inactivates enzymes and destroys harmful microorganisms, extending shelf life.

8. Filling and Packaging – Juice is packed in bottles, cartons, or aseptic bags to retain freshness until consumption.

When designed and operated correctly, a citrus juice processing line ensures every drop of juice meets market standards for taste, texture, and nutrition.

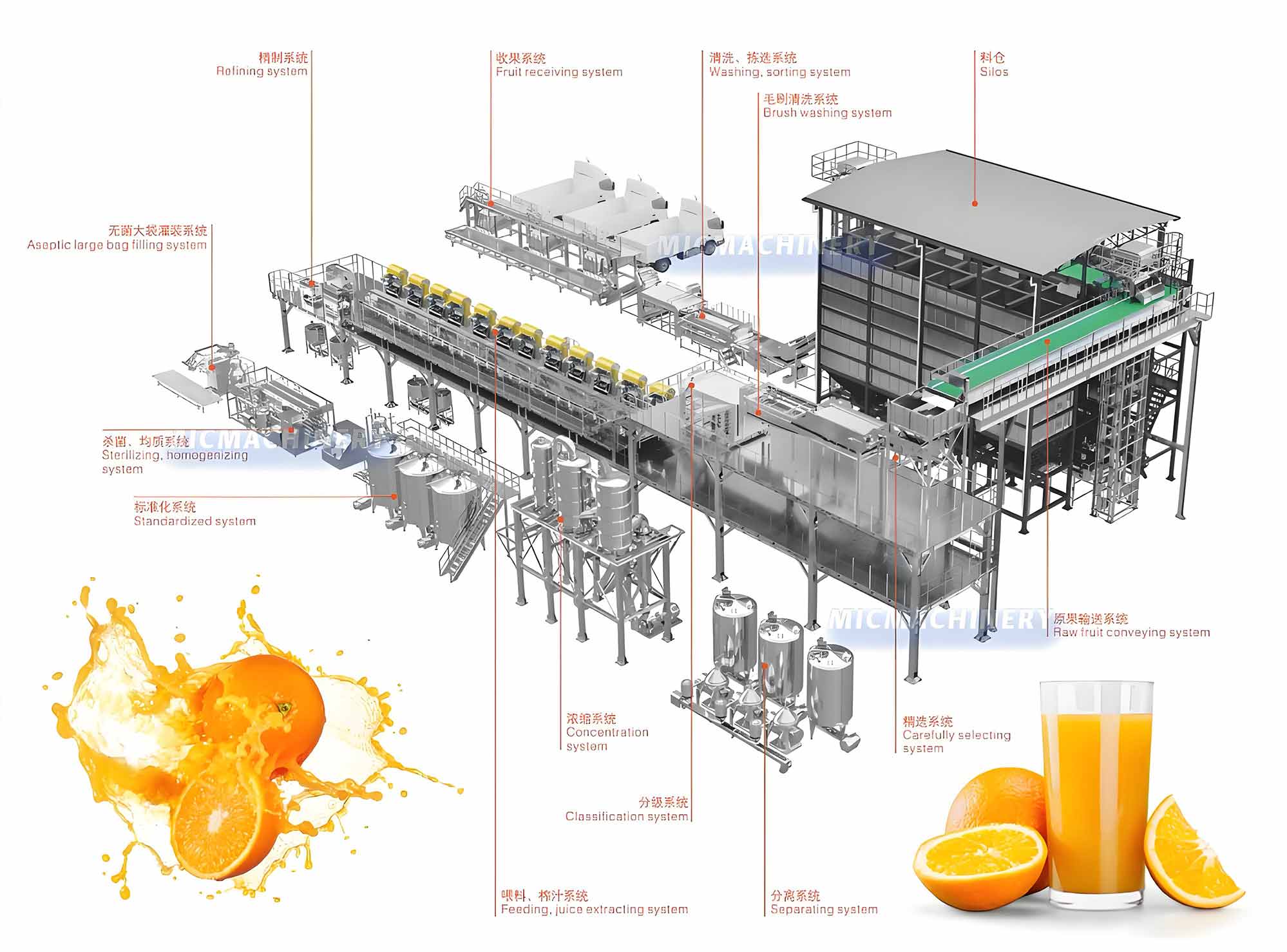

The Orange Juice Production Line in Focus

|

Oranges dominate the global citrus industry, making the orange juice production line one of the most widely used processing setups. These lines are optimized for high juice yield, consistent flavor, and scalability.

In a modern orange fruit processing line, the production flow often includes degassing systems to remove dissolved oxygen (which can degrade flavor), pasteurization to ensure microbiological safety, and aseptic filling machines for long shelf life without preservatives.

Large facilities equipped by experienced orange juice processing line manufacturers often feature fully automated control systems that monitor temperature, pressure, and flow rates at every stage. This automation reduces labor costs and ensures batch-to-batch consistency. |

|

Essential Equipment in Citrus Processing Facilities

A high-quality citrus processing machine and production line integrates multiple pieces of specialized equipment designed for efficiency and product integrity.

Typical machines include:

• Rotary Washers and Conveyor Systems – For continuous cleaning and smooth fruit transport.

• Juice Extractors – Engineered to separate juice from peel with minimal bitterness.

• Pulp Refiners and Clarifiers – To achieve the desired texture and clarity.

• Peel Oil Recovery Systems – For capturing valuable citrus oils used in cosmetics, fragrances, and flavorings.

• Vacuum Evaporators – For producing concentrated juice with reduced water content.

• Aseptic Filling Units – For sterile, long-lasting packaged products.

The design and scale of the citrus juice processing line will vary depending on whether a company targets the fresh juice market, industrial concentrate buyers, or both.

Choosing the Right Manufacturers and Suppliers

When purchasing an orange juice processing line, it’s vital to partner with experienced providers who can deliver reliable, efficient, and compliant systems.

Orange juice processing line manufacturers should offer:

• Tailored plant layouts based on client capacity

• High-grade stainless steel construction for hygiene and durability

• Automated control systems for precision and quality assurance

• Compliance with international safety standards like CE, ISO, and HACCP

Meanwhile, reputable orange juice processing line suppliers can provide:

• Turnkey installation and commissioning services

• Operator training programs

• Spare parts availability and prompt after-sales support

• Cost-effective solutions for both small and large-scale producers

Selecting the right partner can make the difference between an efficient, profitable plant and one that struggles with downtime and inconsistent output.

|

|

|

Beyond Orange Juice: Multi-Citrus Capability

While orange juice remains the most popular product, a flexible citrus processing line can handle lemons, limes, tangerines, and grapefruits with minimal adjustments. The orange fruit processing line can be adapted with modified extraction heads, different filtration settings, and adjustable pasteurization parameters.

This versatility enables year-round production by shifting focus to whichever citrus variety is in season, ensuring consistent utilization of equipment and steady cash flow for producers.

Technical parameters of citrus fruit processing line:

| Raw materials | Fresh orange, orange, lemon, Huyou, grapefruit |

| Final products | NFC fresh juice, concentrated juice, essential oil, pulp (orange velvet, etc.), cysts |

| Capacity | 20 t / D – 2000 t / D |

| Fruit juice yield | ≥ 90% |

| Solid content | 7 ~ 12 Brix |

| Packaging | Sterile bag / glass bottle / PET bottle / roof bag / Tetra Pak |

Sustainability in Citrus Processing

Modern juice production is not only about quality — it’s also about sustainability. Many orange juice production line systems now incorporate:

• Water Recycling Units – To reduce fresh water usage in washing and cleaning stages.

• Energy Recovery Systems – To capture heat from pasteurization and reuse it elsewhere in the process.

• Byproduct Utilization – Peel and pulp can be processed into animal feed, natural flavorings, or dietary fiber products.

Integrating these features into an orange fruit processing line not only benefits the environment but can also create new revenue streams.

|

|

|

Conclusion

Citrus fruit processing is a blend of agricultural knowledge, food science, and engineering precision. Whether you are producing fresh juice for local markets or concentrate for export, the success of your business depends on the efficiency and reliability of your citrus processing machine and production line.

By working with experienced orange juice processing line manufacturers and trusted orange juice processing line suppliers, companies can secure high-performance equipment that delivers consistent quality, reduces waste, and adapts to multiple citrus varieties. From the orchard to the bottle, a modern citrus juice processing line or orange juice production line remains the backbone of a thriving citrus beverage business.