MIC 12-1 Drink Packaging Machine (1000-2000CPH)

MIC 12-1 Drink Packaging Machine

Company Introduction

Jiangsu Mic Machinery is a globally recognized manufacturer of high-quality beverage filling and packaging machinery. Our extensive experience and dedication to innovation allow us to deliver cutting-edge solutions tailored to the unique needs of beverage manufacturers. The MIC 12-1 drink packaging machine is a prime example of our commitment to excellence, designed to enhance the efficiency, reliability, and performance of your production line.

|

|

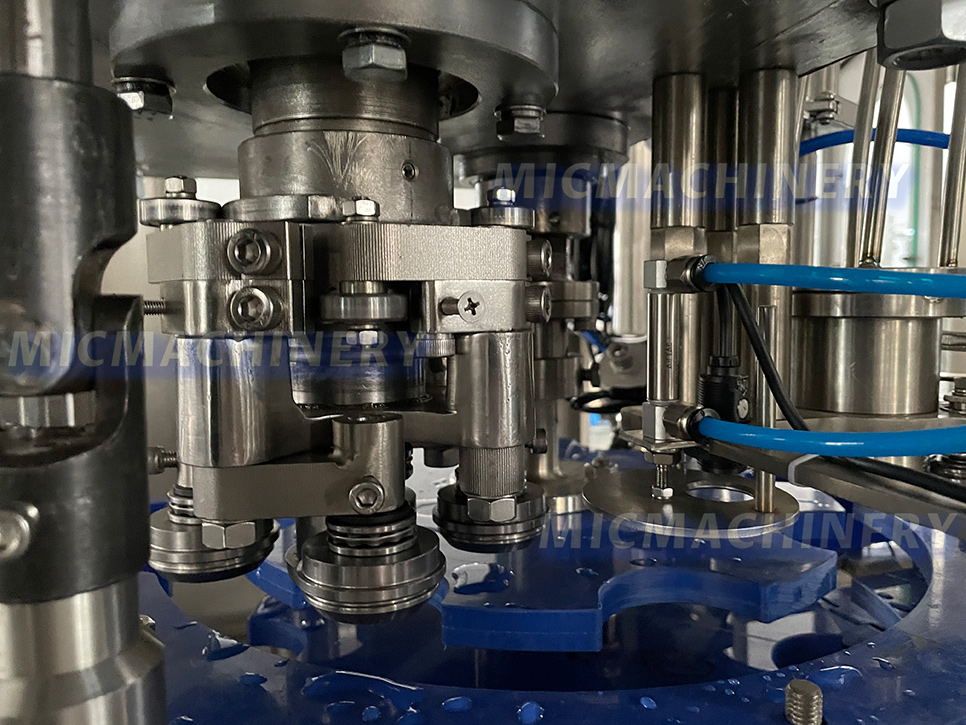

Aluminum can seaming system The aluminum can seaming system ensures airtight, secure seals for beverage and food cans. Designed for precision and reliability, it enhances product freshness and prevents leaks during storage and transport. |

|

Gravity liquid filling system The gravity liquid filling system offers a reliable, efficient solution for accurately filling beverages and liquids. Ideal for various industries, it ensures smooth operation, precision, and minimal product wastage.

|

|

|

|

Liquid nitrogen dispenser The liquid nitrogen dispenser provides precise nitrogen dosing for food and beverage packaging. It enhances product shelf life, prevents oxidation, and ensures reliable, efficient packaging operations. |

Working Principle of Drink Filling Machine

The MIC 12-1 operates using a combination of gravity and pressure-based filling mechanisms, ensuring precise and consistent results. Bottles are conveyed to the filling station, where advanced sensors detect their presence. The machine then fills each bottle with the exact amount of liquid required. Its integrated cold drink packaging machine system ensures a clean and efficient process, minimizing product waste.

The next stage involves automated capping, where bottles are sealed securely to preserve the freshness and quality of the beverages. The entire operation is controlled via an intuitive user interface, allowing operators to monitor and adjust settings with ease. This seamless process guarantees accuracy, speed, and hygiene in every cycle.

Function

The MIC 12-1 drink packaging machine is designed to handle a variety of beverage types, including carbonated drinks, juices, and flavored water. Its versatility allows for the packaging of both glass and PET bottles, accommodating various shapes and sizes.

Equipped with adjustable filling valves and an efficient capping system, the machine can be fine-tuned to meet the specific requirements of different products. Its integration into a cold drink packaging machine setup ensures smooth operation, making it ideal for both small and large-scale production environments.

Advantages of Drink Filling Machine

1、Precise Filling and Sealing

The MIC 12-1 ensures accurate filling and secure sealing, reducing waste and maintaining beverage quality.

2、Enhanced Efficiency

Its high-speed operation significantly boosts production output while reducing manual labor requirements.

3、Cost-Effective Solution

The machine's durable design and energy-efficient features contribute to lower operational costs. Businesses seeking competitive cold drink filling machine price solutions will find this model a valuable investment.

4、Versatility

Designed to handle a wide range of cold beverages, the machine supports multiple bottle types and sizes, making it adaptable to changing market demands.

5、User-Friendly Operation

The intuitive control panel simplifies operation, allowing operators to adjust settings easily and minimize downtime.

6、Hygienic Design

Constructed with high-quality materials, the MIC 12-1 meets stringent hygiene standards, ensuring the safety of beverages throughout the filling and packaging process.

In conclusion, the MIC 12-1 drink packaging machine is a robust, efficient, and versatile solution for beverage manufacturers looking to streamline their production lines. Its competitive cold drink filling machine price and advanced features make it an excellent choice for businesses aiming to enhance productivity while maintaining high-quality standards.

Mic 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |