MIC 18-18-6 Soft Drink Production Line (8000-10000 BPH)

MIC 18-18-6 Soft Drink Production Line: Efficient and Reliable Bottling Solution

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer of advanced beverage production equipment, specializing in providing high-quality solutions for the soft drink, energy drink, and carbonated beverage industries. With years of expertise and cutting-edge technology, we offer automated bottling systems that ensure precision, speed, and efficiency. Our MIC 18-18-6 soft drink production line is designed to meet the high demands of modern beverage manufacturing, offering reliable performance and scalability to adapt to changing market needs. We are committed to helping businesses optimize their production processes, improve product quality, and enhance overall operational efficiency.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

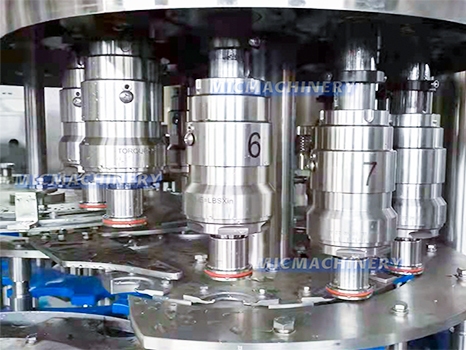

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Working Principle

The MIC 18-18-6 soft drink production line is engineered to integrate multiple production stages into one automated system, significantly reducing labor costs and increasing production speed. The working principle revolves around precise filling, capping, and labeling operations, designed to provide consistent quality in every bottle.

1)Filling Process: The filling system in the MIC 18-18-6 ensures accurate and consistent filling of bottles, crucial for the quality control of soft drink bottling lines. With advanced filling technology, it prevents overfilling, reducing waste and ensuring that each bottle is filled to the exact required level.

2)Capping System: After the filling process, the automated capping mechanism securely seals each bottle, ensuring that the drink stays fresh and protected from contamination. This step is essential to maintain product integrity in drink production line processes.

3)Labeling Process: The line incorporates an automatic labeling system that applies high-quality labels to each bottle. The system ensures that the labeling is precise and consistent, which is essential for branding and consumer recognition. This fully automated labeling process contributes to the high efficiency of the soft drink production line.

4)Control System: The MIC 18-18-6 features an intuitive, user-friendly control panel, allowing operators to monitor and adjust the system easily. The control system helps ensure smooth, uninterrupted production and real-time monitoring of each stage of the bottling process.

Advantages

The MIC 18-18-6 soft drink production line offers a range of advantages that make it a standout solution for beverage manufacturers looking to improve their bottling processes.

1.High-Speed Production

ith its high-speed filling and capping systems, the MIC 18-18-6 can handle large volumes of soft drinks, making it ideal for businesses requiring high output in soft drink bottling lines. This increased efficiency ensures that manufacturers can meet market demands quickly.

2.Automation for Cost Savings: The fully automated production process minimizes the need for manual labor, which reduces labor costs and human error. Automation increases the overall speed of the production line, leading to higher throughput and lower operational costs.

3.Precision and Consistency: Each step in the bottling process—filling, capping, and labeling—is designed for precision. This ensures that every bottle is filled accurately, sealed securely, and labeled consistently, which is critical for maintaining product quality and brand identity across large production runs.

4.Flexibility in Bottle Sizes: The MIC 18-18-6 is adaptable to different bottle sizes and packaging formats, making it versatile for various soft drink products. Whether bottling carbonated beverages, juices, or flavored waters, this production line can handle a wide variety of packaging needs.

5.Energy Efficiency: The system is designed to be energy-efficient, helping companies reduce their overall energy consumption while maintaining high production standards. This focus on sustainability helps businesses lower operational costs and minimize their environmental impact.

6.Easy Maintenance and Operation: The machine is designed for ease of use, with a simple interface that allows operators to monitor and adjust the system quickly. It also requires minimal maintenance, which reduces downtime and keeps the production line running smoothly.

7.Scalability and Adaptability: As your business grows, the MIC 18-18-6 soft drink production line can be scaled to meet higher production demands. Its flexibility makes it an ideal choice for businesses looking to expand or diversify their beverage offerings.

The MIC 18-18-6 soft drink production line offers unmatched efficiency, reliability, and flexibility for modern beverage manufacturing. By incorporating cutting-edge technology and advanced automation, this production line ensures that manufacturers can consistently produce high-quality soft drinks while optimizing their operations for cost savings and speed. Whether you are producing sodas, juices, or flavored drinks, the MIC 18-18-6 is the perfect solution for your bottling needs.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |