MIC 40-40-10 Mineral Water Machine

MIC 40-40-10 Mineral Water Machine

Mic Machinery is a leading manufacturer of advanced beverage packaging equipment, serving customers across the globe with innovative, efficient, and reliable machinery. With a strong focus on quality and precision, we specialize in solutions for the bottled water industry. Our MIC 40-40-10 Mineral Water Machine is designed for high-speed bottling lines, providing unmatched performance and hygiene for modern mineral water plant machine operations.

|

|

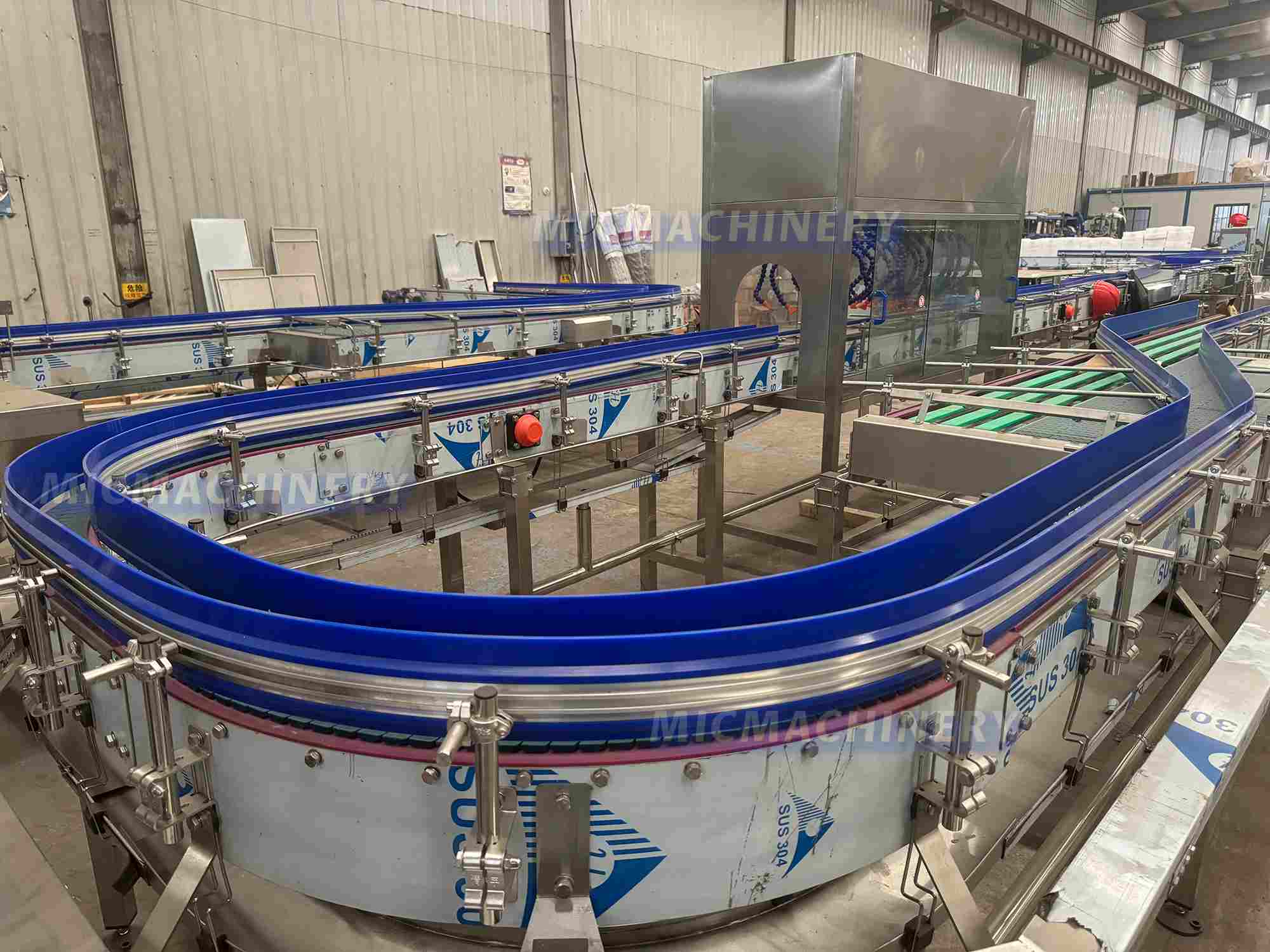

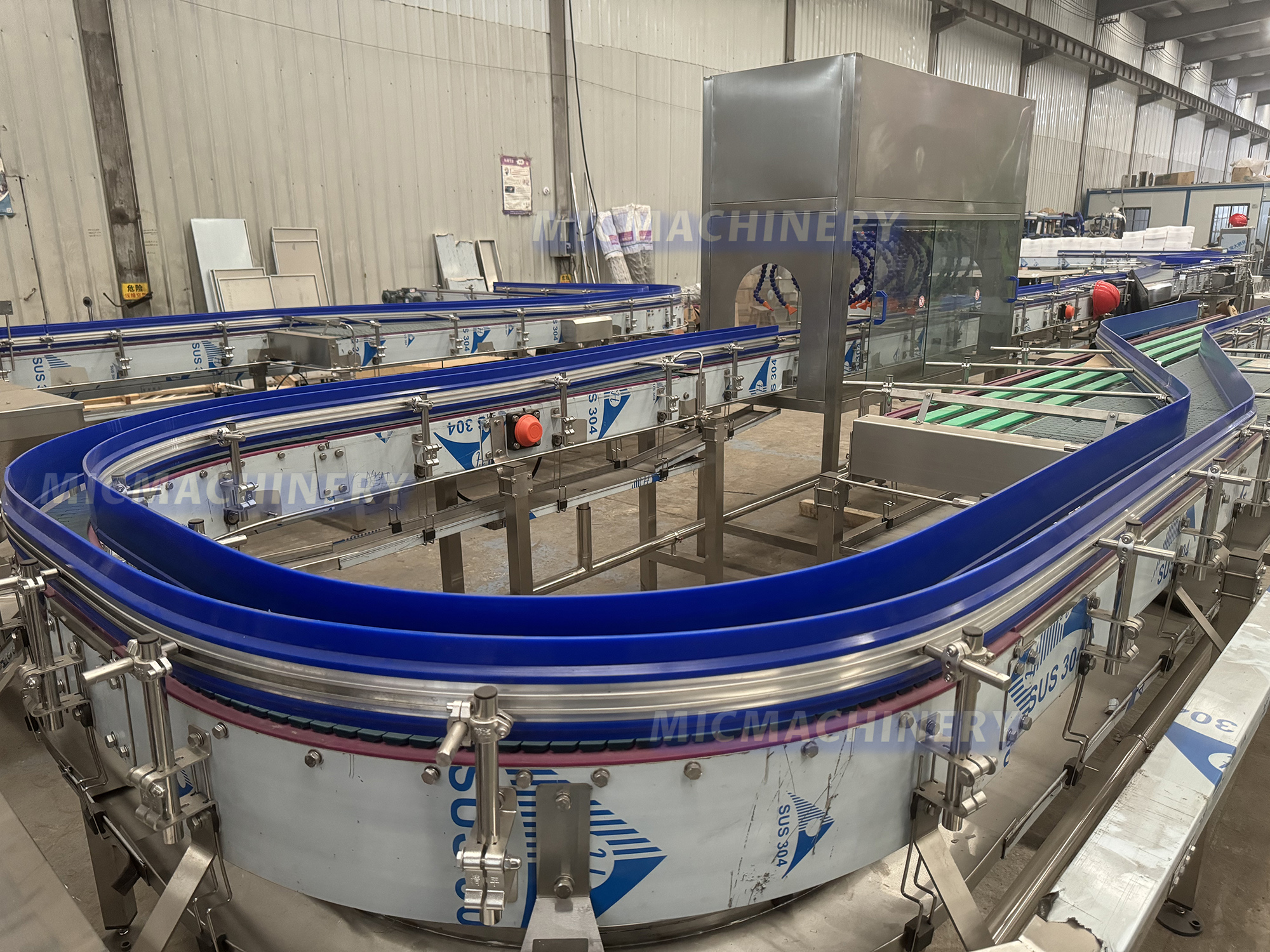

conveyor system Optimize your water filling machine with a high-speed conveyor system for smooth and efficient bottle transportation. Designed for stability and durability, it ensures seamless movement through rinsing, filling, and capping stages. Ideal for packaged drinking water machine setups, it enhances automation and boosts production efficiency. |

|

Electrical Control Panel Optimize your water filling machine with a high-performance electrical control panel for precise automation and efficiency. Our advanced control systems ensure seamless operation, accurate filling, and energy savings. Designed for reliability, they enhance production stability in packaged drinking water machine setups. |

|

|

|

Capping part

- 304 stainless steel construction. No bottle no capping. Capping effect is stable and reliable |

Working Principle

The mineral water machine integrates rinsing, filling, and capping functions into one rotary system:

1)Rinsing Unit (40 heads): Bottles are automatically clamped and flushed with sterilized water to ensure cleanliness before filling.

2)Filling Unit (40 heads): Bottles are filled using gravity or pressure technology to maintain accuracy and prevent spillage.

3)Capping Unit (10 heads): Filled bottles are transferred to the capping station where caps are applied and tightly sealed.

4)Bottle Discharge: Finished bottles are conveyed out for labeling and packaging.

Features and Advantages

▪ High Output Capacity: Capable of processing up to 15,000 bottles per hour for medium to large-scale production lines.

▪ Hygienic Design: All parts in contact with liquid are made from SUS304 or SUS316 stainless steel.

▪ Smart Control System: Equipped with PLC and touchscreen interface for easy monitoring and control.

▪ Integrated Structure: Reduces floor space and improves operational efficiency.

▪ Wide Bottle Range: Supports various bottle shapes and sizes, making it a highly flexible mineral water packaging machine.

Applications

This machine is ideal for bottling purified water, mineral water, and other non-carbonated beverages. It is widely used in commercial mineral water plant machine setups, industrial water production facilities, and large-scale bottling factories. Its adaptability makes it suitable for both local brands and international water producers.

Conclusion

The MIC 40-40-10 Mineral Water Machine provides a complete, automated solution for high-volume water bottling. With excellent speed, hygiene, and performance, it is a top choice for any modern mineral water packaging machine line. Trust Mic Machinery to help optimize your production and support the growth of your water bottling business.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |