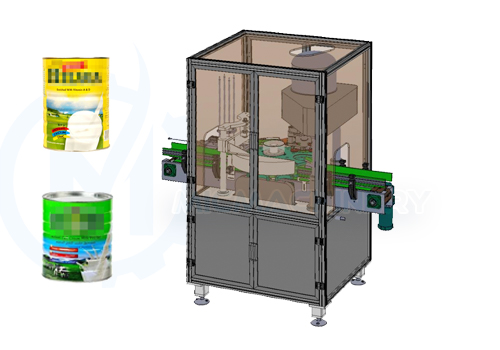

Can Seaming Machine

This machine is suitable for fruit juice beverage, tea beverage, carbonated beverage, protein beverage, canned beverage and canned goods seaming. The production capacity is 50-250 cans per minute, which is the preferred product for a certain scale beverage factory and canned food factory.

In the process of the sealing, the drive, the cans support system and the sealing movement are all mechanical transmission, and the seal adopts the double seal of double rolling wheel.

Machine Principle

After the empty cans pass the conveyor and separated by enter-in cans screw, enter into the caps convey turnplate,the close switch detectes the cans and the falling caps system fall a cap down.The convey caps turnplate bring the cans and caps together into the cans support seat,the filling cans support device under the CAM driving support the cans and resist the pressure head.The cans support seat and the pressure head bring the cans together rotate.The first and the second roll wheels seal along the sealing CAM curve in turns.After sealing the cans-out dialing plate takes the cans out to the convey then delivered.

Machine Features

1. The sealing machine head seal uses the biaxial structure: the feed amount of the first and second roller can be adjusted and controlled separately.

2. Heavy bearing widely used in this machine; the imported bearings are used in the key heavy loading area so that the service life and stability can be extended.

3. High quality components: We use Siemens PLC, daida inverter, touch screen, Yad solenoid valve and Omron proximity switch.

4. Convenient Operation: The production speed can be adjusted on touch screen; The machine will automatically alarm when normal malfunctions happens, and will also give the corresponding reasons. According to the severity of the malfunctions, PLC will judge whether to stop the machine.

5. The machine has good appearance, stable operation and low noise. It is the most ideal filling and seaming equipment in China at present.

| Model | MIC-4A | MIC-6 |

| Number of Capping Head | 4 | 6 |

| Production Capacity | 30-250 cans/min | 60-400 cans/min |

| Can Diameter |

Φ52.3-99mm (Special specifications are 105mm) |

Φ52.3-99mm (Special specifications are 105mm) |

| Can Height | 39-160mm | 39-160mm |

| Power | 5.5KW | 7.5KW |

| Weight | 1500KG | 2000KG |

| Dimension | 2200*1300*1900mm | 2750*1650*1900mm |