MIC Juice Filling and Capping Machine (600-800PCS)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer specializing in high-quality beverage filling and packaging solutions. With years of experience and innovation in the field of juice filling equipment, we have established ourselves as a trusted name for companies seeking reliable and efficient machines. Our expertise spans across various filling and capping machines designed for different production capacities, ensuring that businesses, from startups to large enterprises, can scale their operations with the most advanced technology available.

At Jiangsu Mic Machinery, we provide comprehensive solutions, including juice filling and capping machines that cater to the needs of the beverage industry. We are committed to delivering high-performance machinery that is both cost-effective and built to last, ensuring that your production process runs smoothly and efficiently.

|

|

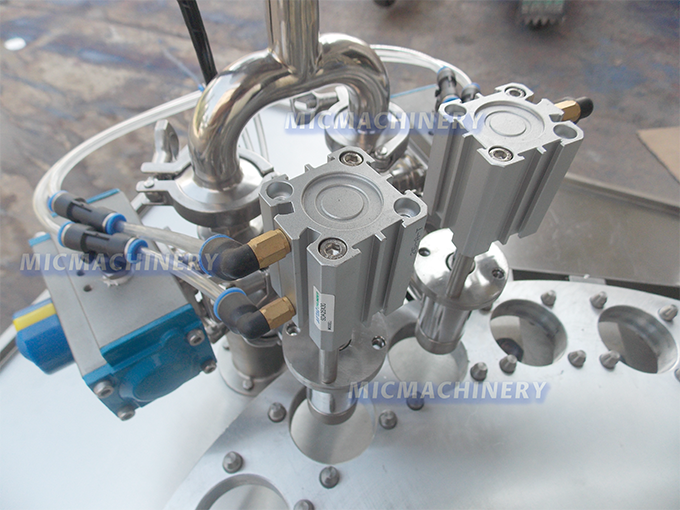

Filling station |

|

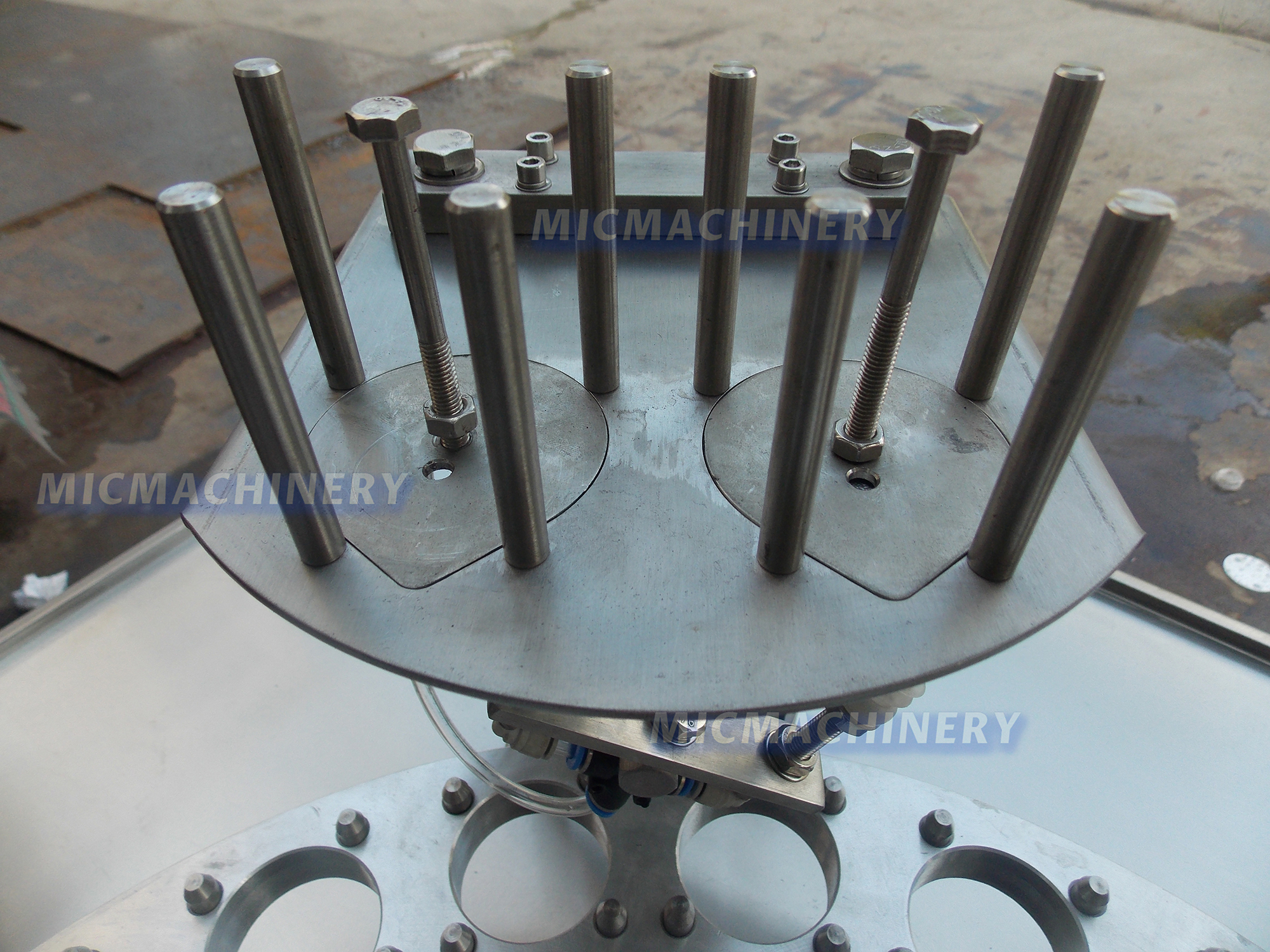

Foil loading rack

|

|

|

|

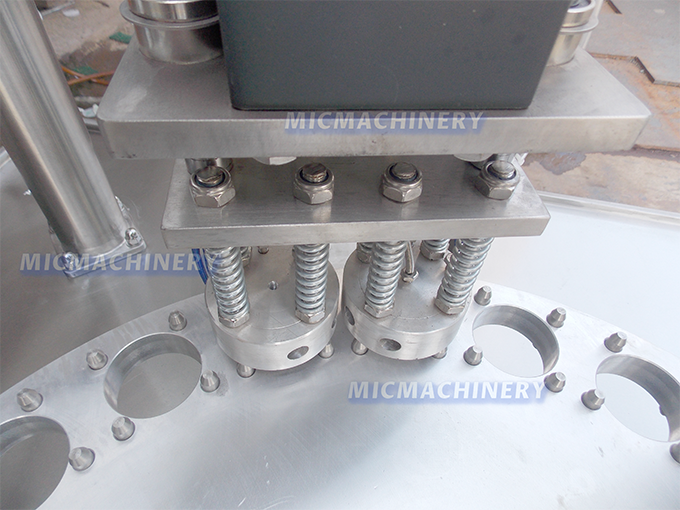

Foil sealing

|

Working Principle of Juice Filling Machine

The MIC juice filling and capping machine operates with an integrated filling and capping system to ensure an efficient and automated process. This machine features a precise filling process, designed to handle a wide variety of bottle sizes and types. The operation is fully automated, reducing the need for manual intervention and ensuring high-speed production.

Filling Process: The machine uses a gravity filling system to transfer the juice into bottles with high accuracy. This method ensures that each bottle is filled to the correct level, minimizing overfills and underfills. The juice filling machine maintains precision in every cycle, guaranteeing consistent product quality and volume for each container.

Capping Process: Once the bottles are filled, the machine automatically moves to the capping stage. The capping unit tightly seals each bottle, ensuring that the juice remains fresh and secure during storage and transportation. The juice filling and capping machine is designed to handle a variety of caps, including screw-on caps, ensuring compatibility with different packaging formats.

Control System: The machine is equipped with a user-friendly control panel that allows operators to set and monitor the entire process. The control system provides real-time feedback, helping to detect any issues such as bottle misalignment or filling irregularities, which ensures minimal downtime and maximum efficiency.

Function and Advantages of Juice Filling Machine

The juice filling machine is engineered to handle high-speed production lines, making it ideal for medium to large-scale juice manufacturing facilities. With a capacity of 600-800 bottles per minute, the MIC juice filling and capping machine is designed to enhance throughput while maintaining product quality. Here are some of its key functions and advantages

1、High-Speed Production

The juice filling and capping machine can handle 600-800 bottles per minute, offering a fast and efficient solution for high-demand juice production. Its automation ensures that the production process is smooth and continuous, minimizing delays and maximizing output.

2、Versatility

This machine can handle various types of juice, including fruit juices, flavored waters, and other non-carbonated beverages. The filling and capping system is adaptable to different bottle sizes and shapes, making it a versatile addition to any production line.

3、Reduced Labor Costs

The fully automated filling and capping process reduces the need for manual labor, which helps to lower operational costs. The automation also ensures a higher level of consistency in the filling and sealing processes, which is crucial for product quality and consumer satisfaction.

4、Precision and Accuracy

The juice filling machine is equipped with advanced filling technology that ensures accurate and consistent juice filling, minimizing product waste and ensuring each bottle is filled to the desired level. This precision also helps maintain the taste and quality of the juice, ensuring it meets customer expectations.

5、Durability and Reliability

Built with high-quality materials, the juice filling and capping machine is designed for long-lasting performance. It can withstand continuous operation in demanding production environments, making it a reliable choice for businesses seeking machinery that offers both high output and low maintenance.

6、Hygienic Design

Hygiene is a top priority in beverage production, and this machine is designed with easy-to-clean surfaces and food-grade materials. Its smooth surfaces prevent contamination, ensuring that the juice remains fresh and safe for consumers. The hygienic design of the juice filling equipment helps businesses comply with industry standards and regulations.

7、Energy Efficiency

The MIC juice filling and capping machine is designed with energy-efficient components that reduce electricity consumption while maintaining optimal performance. This energy-saving design helps businesses lower their operational costs while minimizing their environmental impact.

8、Customizable Options

Jiangsu Mic Machinery offers customization options to meet the specific needs of each business. Whether you need adjustments for specific bottle sizes, cap types, or production speeds, we provide flexible solutions tailored to your operational requirements.

In conclusion, the MIC juice filling and capping machine is a highly efficient and reliable solution for medium to large-scale juice production. Combining advanced technology, precision engineering, and a user-friendly interface, it ensures that your juice production process runs smoothly and meets the highest quality standards. With its versatility, speed, and cost-effectiveness, this juice filling and sealing machine is an invaluable asset for businesses looking to enhance their production efficiency and product quality.

At Jiangsu Mic Machinery, we are committed to providing top-tier juice filling equipment that supports your business's growth and success. Contact us today to learn more about how our juice filling machine solutions can help you optimize your production process.

| Diameter | 1100*1100*1600mm |

| Weight | 350KGS |

| Power | 2 KW |

| Voltage | 110V/ 60Hz 1P |

| Air pressure | 0.6-0.8Mpa |

| Capacity | 600-800 pcs/hour |

| Air consumption | 0.6m³/min |

| Heating type | electrical heated |

| Working position | 6 |

| Machine frame | SUS 304 |

| Item | Brand |

| PLC | OMRON |

| Touch Screen | WEINVIEW |

| Motor | DINGYI |

| Magnetic Valve | JELPC |

| AC Contactor | SCHNEIDER |

| Temperature Control | SIMP |

| Relay, Circuit Breaker | DELIXI |

| Divider | REP |

| Pneumatic Component | AKS |