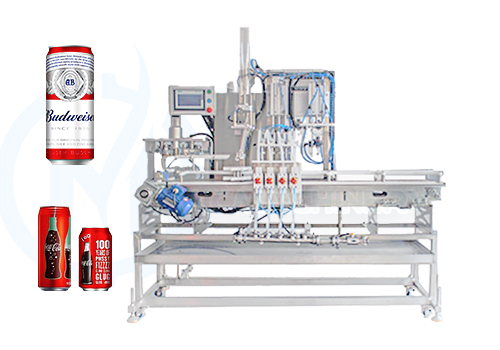

MIC Linear Drink Filling Machine (1000-1500CPH)

MIC Linear Drink Filling Machine

Machine Is Suitable For

The MIC Linear drink filling machine is a versatile solution designed for businesses in the beverage industry. It is particularly suitable for filling various types of liquids, including carbonated beverages, juices, flavored water, and other cold drinks. This machine is ideal for small to medium-sized production facilities that require precision, efficiency, and adaptability in their operations.

Its advanced features make it compatible with a variety of container sizes and materials, such as PET, glass bottles, and aluminum cans. Whether you're producing single-serve drinks or larger multi-serve bottles, the MIC Linear cold drink packing machine ensures consistent performance and superior quality.

|

|

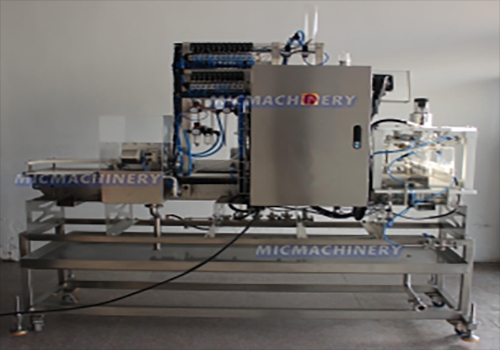

Machine |

|

Filling head The beer canning machine filling head ensures precise and consistent filling, using advanced technology to control beer volume and minimize waste. Designed for efficiency, it supports high-speed operations while maintaining product quality. |

|

|

|

Conveyor |

Working Principle of Drink Filling Machine

The MIC Linear drink filling machine operates on a linear design, which optimizes the production process while ensuring accuracy and reliability. Here’s how it works:

1)Bottle Feeding: Containers are automatically fed into the machine via a conveyor system. The linear arrangement minimizes space requirements while ensuring smooth transportation.

2)Rinsing: Before filling, the containers are thoroughly rinsed using high-pressure water jets to eliminate contaminants and prepare them for the filling process.

3)Filling: The machine uses a gravity or pressure-based system to dispense the liquid into the containers. This ensures precise and spill-free filling, even for carbonated drinks.

4)Capping: Once filled, the containers are capped securely to maintain freshness and prevent leaks. The capping mechanism is designed to handle different cap types with precision.

5)Output: The filled and capped containers are then moved to the next stage of production, such as labeling or packaging, seamlessly integrating with other equipment like cold drink packaging machines.

Advantages of Drink Filling Machine

The MIC Linear drink filling machine offers numerous benefits, making it a valuable addition to any production line:

1、Compact Design

The linear layout saves floor space while maintaining high operational efficiency.

2、Precision and Consistency

Advanced filling technology ensures accurate liquid levels in every container, reducing product wastage.

3、Versatility

It accommodates various bottle shapes and sizes, making it adaptable to different product lines.

4、Hygienic Operation

The stainless steel construction and clean-in-place (CIP) system ensure compliance with strict hygiene standards, making it ideal for beverages.

5、Energy Efficiency

Engineered to consume minimal energy, the machine helps reduce operational costs without compromising performance.

6、Ease of Use

The intuitive control panel allows operators to monitor and adjust the process effortlessly, ensuring smooth operation.

7、Integration Capability

The machine integrates seamlessly with cold drink packing machines and cold drink packaging machines, creating a fully automated production system.

8、Durability

Built with high-quality materials, the MIC Linear drink filling machine is designed for long-term use with minimal maintenance.

In conclusion, the MIC Linear drink filling machine is a reliable, efficient, and cost-effective solution for beverage manufacturers. Jiangsu Mic Machinery is committed to delivering top-tier machinery that meets your production needs, ensuring your business stays competitive in the industry.

|

Equipment Parameter |

MIC 4-4-1 Beer Can Rinser Filler Seamer |

|

|

1 |

Dimension (L*W*H) |

2.00×0.91×1.85M |

|

2 |

Equipment Weight |

400KG |

|

3 |

Packing Size (L*W*H) |

2.20×1.15×2.05M |

|

4 |

Packing Weight |

550KG |

|

5 |

Production Capacity |

1200- 1500pcs/ H(330ml) 396-495L/ H 1000- 1200pcs/ H(500ml) 500-600L/ H |

|

6 |

Voltage |

380V-3 Phases-50Hz (Customized) |

|

7 |

Power port |

3P+ N+G |

|

8 |

Power consumption |

2.0-3.5KW |

|

9 |

Main Material |

SUS304 |

|

10 |

Beer Storage Tank Pressure |

0.15-0.2Mpa (22-30PSI) 1.5" Tir-clamp |

|

11 |

Compressed Air |

0.5-0.7Mpa (75.0- 105PSI) OD:Ф10mm |

|

12 |

Jacking Can Pressure |

0.20-0.30Mpa (30-45PSI) |

|

13 |

CO2 Pressure |

0.15-0.2Mpa (22-30PSI) OD:Ф10mm |

|

14 |

Flip- Rinse Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |

|

15 |

Exit- Rinse Water Pressure |

0.15-0.20Mpa(22-30PSI) 1.5" Tir-clamp |