MIC Manual Soft Drink Production Line (8CPM)

MIC Manual Soft Drink Production Line

Machine is Suitable For

The MIC Manual Soft Drink Production Line is ideal for small to medium-scale beverage manufacturers who require a flexible, efficient, and cost-effective solution for producing a variety of soft drinks. This line is suitable for the production of soft drink production line, carbonated drink production line, and energy drink production line products, allowing manufacturers to cater to diverse market demands. Whether you're producing sparkling sodas, flavored water, energy drinks, or other carbonated beverages, this manual production line provides a reliable foundation for quality production.

This line is designed to cater to producers who prefer manual oversight and control over their production process while still benefiting from the speed and consistency that automated systems offer. It is especially ideal for businesses just starting out or those with more specific, low-volume production needs.

|

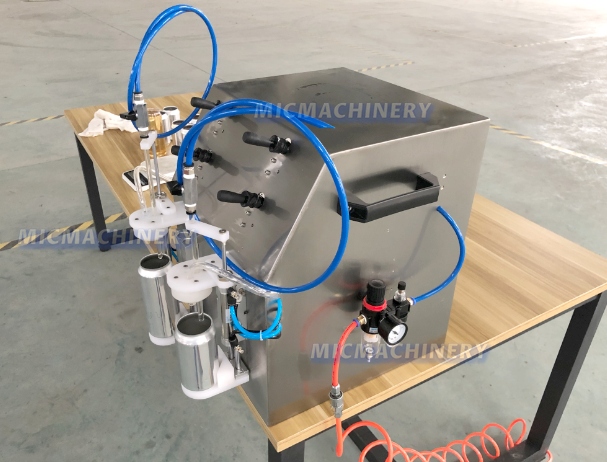

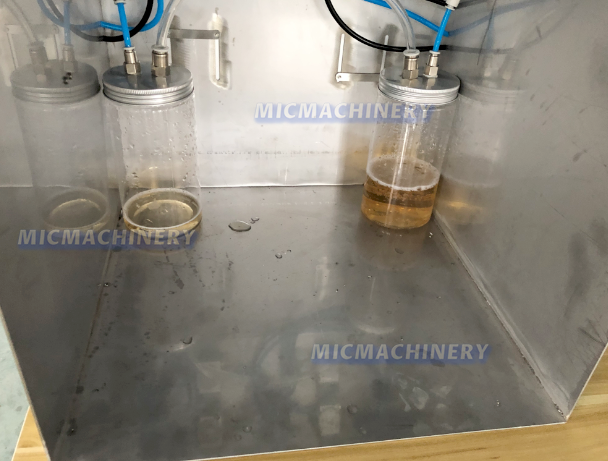

Filling Head The filling head of our beer canning machine ensures precise and consistent filling. It features advanced technology for accurate volume control, minimizing waste while maintaining high-quality standards in every can.

|

|

Control Button |

|

|

Material Barrel The material barrel of our beer canning machine is designed for durability and efficient beer storage. Made from high-quality, corrosion-resistant materials, it ensures safe, hygienic handling and easy access during the filling process. |

Machine Features

The MIC Manual Soft Drink Production Line is equipped with a wide range of features designed to meet the varying needs of beverage manufacturers. Below are the key features:

· Manual Operation with Precision Control: The production line provides manual control over each production stage, giving operators the flexibility to monitor and adjust settings according to specific production needs. This feature is especially beneficial for small batch or artisanal beverage makers who need detailed control over their products.

· Flexible Beverage Production: This line is capable of producing a wide variety of drinks, including carbonated drink production line beverages such as sodas, sparkling waters, and energy drinks. The line's versatility allows for easy transitions between product types, enabling manufacturers to switch between different drinks without major downtime or adjustment.

· Durable Construction: The equipment is built with high-quality materials that ensure long-lasting performance and durability. From the filling machine to the capping and labeling system, every part of the production line is designed to withstand frequent use and provide consistent results over time.

· Accurate Filling and Sealing: The soft drink production line includes high-precision filling equipment that minimizes spillage and ensures accurate amounts of product in each bottle. The capping system provides secure seals to prevent leaks, ensuring that each product is properly sealed for freshness and quality.

· Manual Control of Key Stages: While automated lines offer high-speed production, the manual system on this line allows for more personal oversight of key stages such as filling, capping, and labeling. Operators can closely monitor and adjust parameters, providing a hands-on approach to quality control.

· Easy Maintenance and Setup: The MIC Manual Soft Drink Production Line is designed for simple maintenance and easy setup. Its straightforward design means less time spent on troubleshooting or repairs, making it ideal for manufacturers who may not have a large technical team on hand.

· Space-Saving Design: The compact layout of the production line allows it to fit into smaller production facilities, maximizing space while still delivering high-quality beverage production. This feature is ideal for businesses with limited floor space but a need for versatile production capacity.

Machine Introduction

The MIC Manual Soft Drink Production Line is a high-quality, manually operated system designed to meet the needs of small to medium-scale soft drink manufacturers. The line combines the best of manual oversight and automated technology to deliver a reliable and flexible production process. Ideal for producing soft drink production line products such as sodas, energy drinks, and sparkling water, this line is built to handle a range of beverages with ease.

The production line is equipped with high-precision filling and capping machines that ensure accurate amounts of liquid are dispensed into each bottle while maintaining proper sealing. The labeling system ensures that each product is marked with clear, accurate, and professional labels, while the overall design focuses on user-friendly operation and flexibility.

The MIC Manual Soft Drink Production Line is especially well-suited for businesses in the early stages of production or those looking for a more hands-on approach to beverage manufacturing. Whether you are focusing on carbonated drink production line products or expanding your range to include energy drinks, this line provides a reliable foundation for growth.

Advantages

Cost-Effective: The manual system is a cost-efficient option for smaller producers who may not require fully automated systems but still need to maintain high-quality production standards. The system allows for more affordable entry into the soft drink market without compromising on production quality.

Flexibility: The MIC Manual Soft Drink Production Line can handle a wide range of beverages, including those from the energy drink production line or carbonated drink production line. This flexibility ensures that producers can meet changing consumer demands by easily switching between different types of drinks.

Quality Control: With manual control over key production stages, operators can monitor and adjust the process to ensure each bottle meets quality standards. This attention to detail is especially valuable for small-batch or premium beverages.

Scalability: The line’s design allows for easy scalability. As your production needs grow, you can expand the system by adding additional machines or upgrading components, ensuring long-term sustainability.

User-Friendly: Designed with ease of use in mind, this system requires minimal training for operators. The user-friendly interface allows for smooth operation with simple adjustments, making it an ideal choice for businesses with limited technical resources.

In conclusion, the MIC Manual Soft Drink Production Line offers a reliable, flexible, and cost-effective solution for small to medium-scale soft drink manufacturers. With its precision, durability, and ease of use, it provides an ideal foundation for producing high-quality beverages across a range of categories, from soft drink production line products to energy drink production line beverages. At Jiangsu Mic Machinery, we are dedicated to delivering high-performance solutions that help you streamline your production process and bring your products to market efficiently.

| Filling Heads | 2 Pieces |

| Production Capacity |

8 Cans per minute based on 330 ml and 550 ml |

| Filling Pressure | 0.4-0.6Mpa |

| Can Diameter Range | Ф40-90MM |

| Can Height | 92-168MM |

| Dimension | 575*550*480MM |

| Weight | 15KG |

| Name | Brand |

| Buttons | Schneider (France) |

| Touch screen | Siemens (Optional) |

| AC Contactor | Schneider (France) |

| PLC | Mitsubishi (Japan) / Siemens (Optional) |

| Frequency changer | Schneider (France) |

| Air cylinder | AirTAC (China) / FESTO (Optional) |

| Solenoid valve | AirTAC (China) / FESTO (Optional) |

| Relay | Autonics (Korea) / Omron (Optional) |

| Proximity switch | Autonics / Omron (Optional) |