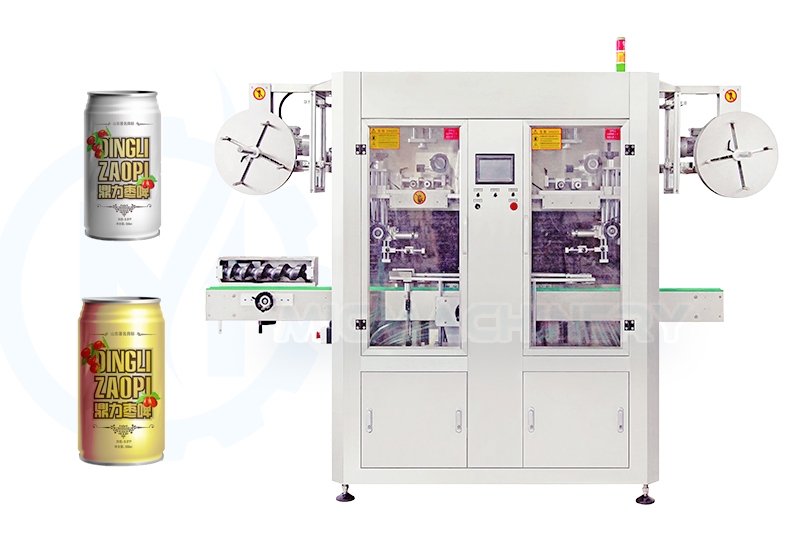

MIC-250D Automatic Can Labeling Machine (45 Meter/Min)

Introduction to Our Automatic Can Labeling Machine

At Jiangsu Mic Machinery, we specialize in providing cutting-edge labeling solutions designed to optimize production efficiency in various industries. Our Automatic Can Labeling Machine is specifically engineered to handle high-speed, high-precision label application for a wide range of cans. Whether you’re in the beverage, food, or chemical industry, this machine ensures that your cans are labeled quickly, accurately, and consistently, enhancing the overall appearance and quality of your products.

Designed with flexibility in mind, our beer can labeling machine and general can labeling machine capabilities ensure that the system can easily accommodate different can sizes, materials, and label formats, making it an ideal solution for diverse production needs.

|

Main technical parameters of the equipment: Voltage: 1.Host machine; AC220V, 50/60HZ, 4KW, single-phase 2.Production speed:18000-21000 b/h as 100mm label. 3.The standard length of label is 300mm and the speed can be adjusted accord to customer’s requirements. The speed will be faster if the label is shorter. 4.Diameter of bottle body : ∮40mm-∮100mm 5.Length of label:100mm 6.Thickness of label:0.045mm 7.Material of label:PVC、PET、 OPS |

|

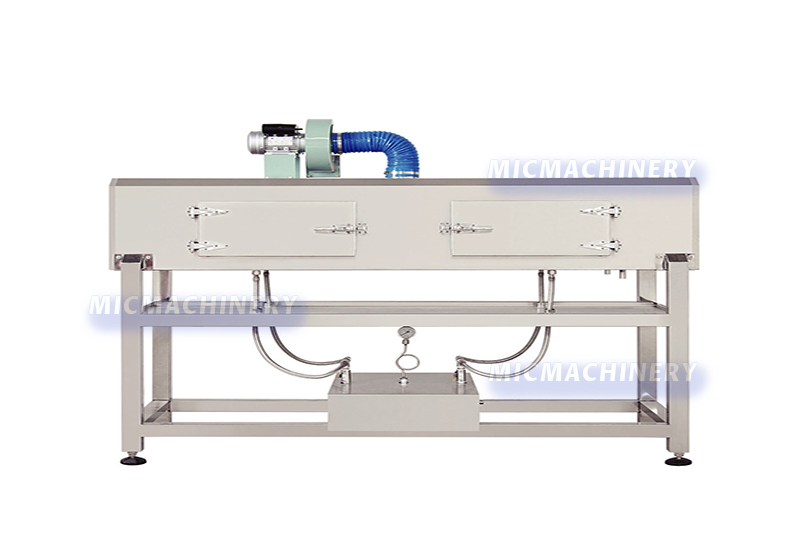

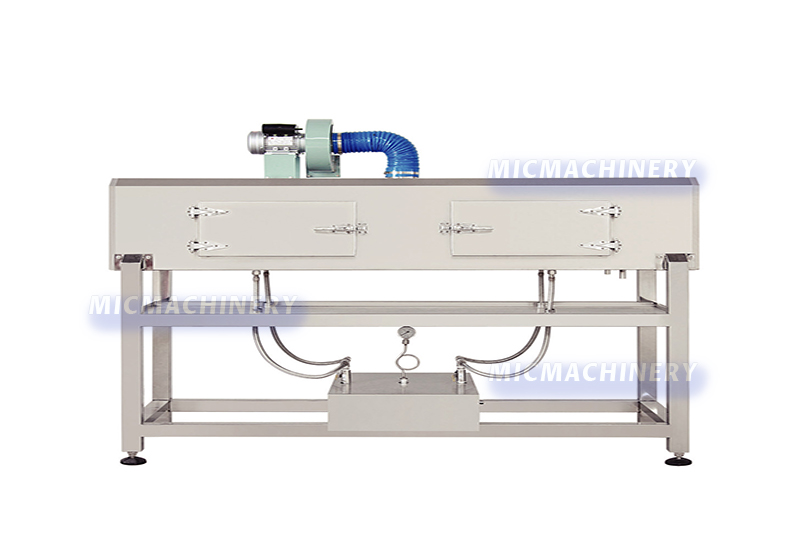

SLM-1800 Steam Shrink Tunnel 1. In the case of different and irregular round bottles, square bottles and flat bottles etc, the new-style both steam and electricity shrinking oven is easy to adjust and maintain. It has an even shrinking .2.The distribution of low-pressure steam drum and sqouting way of steam are uniform and designed with seamless tube. 3.The nozzle is divided to be adjustable three segments and the height , position and steam output of every segment can be adjusted respectively so as to gain the perfect shrinking effect. 4 .The whole machine is made of stainless steel with heat preservation, which not only saves energy, but also comply with the international safety standard. 5 .The stainless steel defrosting tray collects condense water. |

|

|

Stream Generator

The water is fed into the series of wholly automatic electrical heating generator by high pressure potential vortex pump made of copper with short water-supply time and durable service. A floating ball for liquid level is fixed in the water tank to automatically control the water inlet. Working system is all automatically controlled. After connecting the water supply and power supply for 5 minutes or so, it can output the steam continuously with a high level of working efficiency. |

Description of the Automatic Can Labeling Machine

The Automatic Can Labeling Machine is built to deliver precision and speed for high-volume production lines. Capable of labeling various can types, including beverage cans, food cans, and beer cans, this machine ensures that every label is applied securely, without wrinkles or misalignment. The system can handle aluminum, tin, and other can materials, offering versatile labeling solutions to meet the needs of your production line.

The beer can labeling machine functionality ensures that your cans, whether they are small craft beer bottles or large commercial cans, are labeled accurately and efficiently. This feature is particularly important for breweries that require fast, high-volume labeling while maintaining quality and brand consistency. The machine can easily handle different label styles, from front-and-back to wrap-around labeling, making it adaptable to various branding requirements.

Our can labeling machine is equipped with advanced sensors and control systems that ensure consistent label placement across all cans, even at high speeds. With a user-friendly interface, operators can easily set up and adjust the machine for different can sizes and labels, minimizing downtime between product runs and boosting overall productivity.

Key Features:

- High-speed operation for large-scale production.

- Precise label placement with advanced sensors and automation.

- Versatile design to handle a variety of can sizes and materials.

- User-friendly interface for easy setup and quick adjustments.

- Durable construction for long-term performance in demanding environments.

Conclusion

Jiangsu Mic Machinery’s Automatic Can Labeling Machine is the perfect solution for businesses looking to streamline their production process with fast, reliable, and high-quality labeling. Whether you need a beer can labeling machine or a can labeling machine for other types of cans, our equipment guarantees precision, flexibility, and efficiency. Let us help you improve your production line and product packaging with our advanced labeling technology.

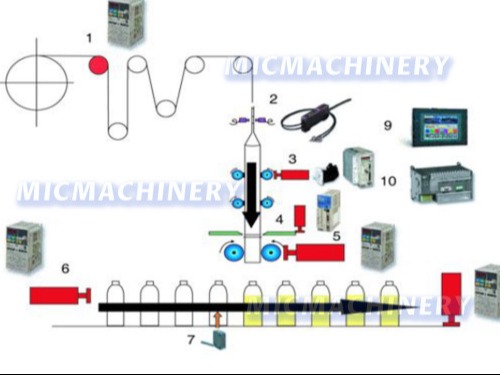

Description of the machine

Synchronized transmission, any change of transmission belt will be finished quickly. Compared to the type of traditional multilayer whose change and maintain need more than six hours ,it’s maintenance is easy and maintain is simple ,so it doesn’t influence production.

Unit cutter head plane design in China which apply to the container of ∮40mm—∮70mm.you never need to change or debug it. It also has unique light touch human-machine screen, that means, auto search original location as well as safety and convenience which is ahead of other congener products.

Single shrinking label feed plane ,reasonable height which is convenient to fix the label ;micro-computer auto figure which avoid enactment and adjustment .you only need to press it lightly ,the label will detect and locate automatically .The change of label is quick and convenient, besides ,the cut place is absolutely exact .

Label feeding equipment :driving synchronized tensility control the supply of label ,the supply ability is 90meters per minute, volume label supply plane is ∮500mm,the internal diameter of paper tube will be 4’ ,8’,10’ .the configuration of label feeding is stable tensility which enable the exact length of label and the stable ,quick supply of label .The center pillar apply step by step shoot label structure and the speed is 150B per minute for 100mm label.

The newly designed cutter head use step by servo motor driving which speed is high ,action is exact ,the cut is in order and the shrinking is beautiful .This design cooperate with the label synchronized location structure enable the precision of cut location within 1mm.

Many emergency stop buttons enable emergency stop at the proper position along the production which guarantee the safe production.

This is the description of sleeve labeling machine, bottle sleeve machine, shrink sleeve label machine.

A sleeving machine for bottles is a specialized piece of equipment used in the packaging industry for applying shrink sleeve labels to bottles of various sizes and shapes. These machines use advanced technology to apply labels quickly and accurately, helping you achieve a professional and eye-catching look for your products.

One of the main advantages of using a sleeving machine for bottles is its ability to accommodate a wide range of bottle shapes and sizes. Whether you're labeling wine bottles, juice bottles, or any other type of bottle, a sleeving machine can help you achieve a consistent and professional look for your products.

Another benefit of using a sleeving machine for bottles is its efficiency. With the ability to apply labels at high speeds, these machines can help streamline your production process and increase your output. This can be especially useful for businesses that need to label large volumes of bottles quickly and consistently.

When selecting a sleeving machine for bottles, it's important to consider factors such as the machine's speed, accuracy, and ease of use. You'll also want to ensure that the machine is compatible with the types of bottles you're labeling, as well as the size and shape of the labels you need.

Overall, a sleeving machine for bottles is a valuable investment for businesses that want to enhance their packaging and labeling capabilities. By using a specialized machine, you can improve your efficiency, increase your output, and ultimately improve your bottom line.

Technical Parameters

|

Input Power Supply of Blower |

1,220VAC 0.75KW |

|

Working Pressure |

≤0.1Mpa |

|

Weight |

230kg |

|

Steam Consumption |

20-30Kg/h |

|

Size of Oven Body |

L1800mm×W600mm×H450mm |

|

Transporting Speed |

0-35m/min |

Quotation for the machine

|

Item |

Name |

Amount |

Unit |

Configuration |

Unit Price |

Total price |

Remark |

|

1 |

Sleeve labeling machine |

1 |

set |

4kw |

|

SLM-252D |

|

|

2 |

Shrink tunnel |

1 |

set |

0.75kw |

SLM-1800 |

||

|

3 |

Steam generator |

1 |

set |

24kw |

SLM-1200 | ||

|

4 |

mold |

2 |

pcs |

||||

|

5 |

Conveyor |

7 |

m |

||||

|

FOB SHANGHAI Total Price :USD25000 |

|||||||

Technical Parameters

|

Input Power Supply |

220V 24kw |

|

Steam Pressure |

0.25-0.4Mpa |

|

Vapor Generation |

24kg/h |

|

External Dimension |

L600mm x W550mm x H1200mm |

|

Weight |

96Kg |

|

NO. |

Name |

Amount |

Unit |

Brand |

Origin |

|

1 |

PLC |

1 |

Set |

Siemens |

German |

|

2 |

Touch Screen |

1 |

Set |

Siemens |

German |

|

3 |

High-speed Optical Fiber Sensors |

2 |

Pc |

Panasonic |

Japan |

|

4 |

OPTICAL SENSORS |

4 |

Pc |

Panasonic |

Japan |

|

5 |

Label Sending Servo Motor |

2 |

Set |

Panasonic |

Japan |

|

6 |

Label Cutting Servo Motor |

2 |

Set |

Panasonic |

Japan |

|

7 |

Bottle Separate Ac Motor |

1 |

Set |

Panasonic |

Japan |

|

8 |

Bottle Separate Converter |

1 |

Set |

Panasonic |

Japan |

|

9 |

Bottle Carrying Ac Motor |

1 |

Set |

Panasonic |

Japan |

|

10 |

Bottle Carrying Converter |

1 |

Set |

Panasonic |

Japan |

|

11 |

Conveyor Converter |

1 |

Set |

Panasonic |

Japan |

|

12 |

Ac Contactor |

2 |

Pc |

Schneider |

France |

|

13 |

2P air switch |

1 |

Pc |

DELIXI |

china |

| 14 |

24V relay |

13 |

Pc |

Schneider |

France |

Toolbox detailed list

|

NO |

Name |

Specification |

Quantity |

|

1 |

Open wrench |

14、12、8、10(4 total) |

1set |

|

2 |

Movement wrench |

250*30 |

1set |

|

3 |

Inner hexagonal wrench |

7 total |

1set |

|

4 |

Clubs screwdriver |

6*100mm、3*75mm |

1set |