MIC 40-40-10 Automatic Water Bottle Packing Machine

MIC 40-40-10 Automatic Water Bottle Packing Machine

Mic Machinery is a leading manufacturer specializing in advanced bottling solutions. Known for delivering high-quality water bottle packaging machine systems, we focus on innovation, reliability, and efficiency. Our expertise ensures that clients worldwide receive top-performing equipment designed to meet modern production demands.

|

|

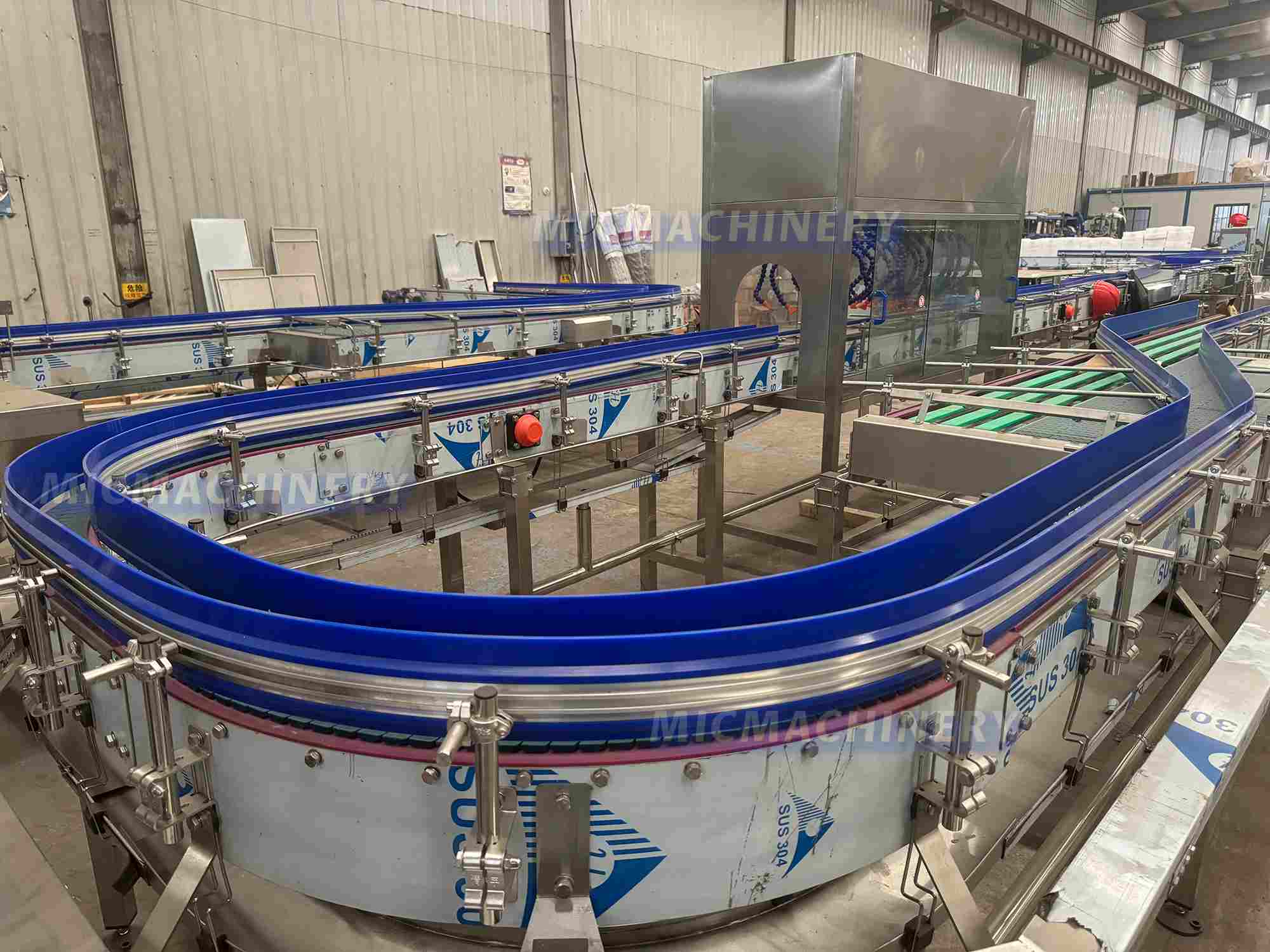

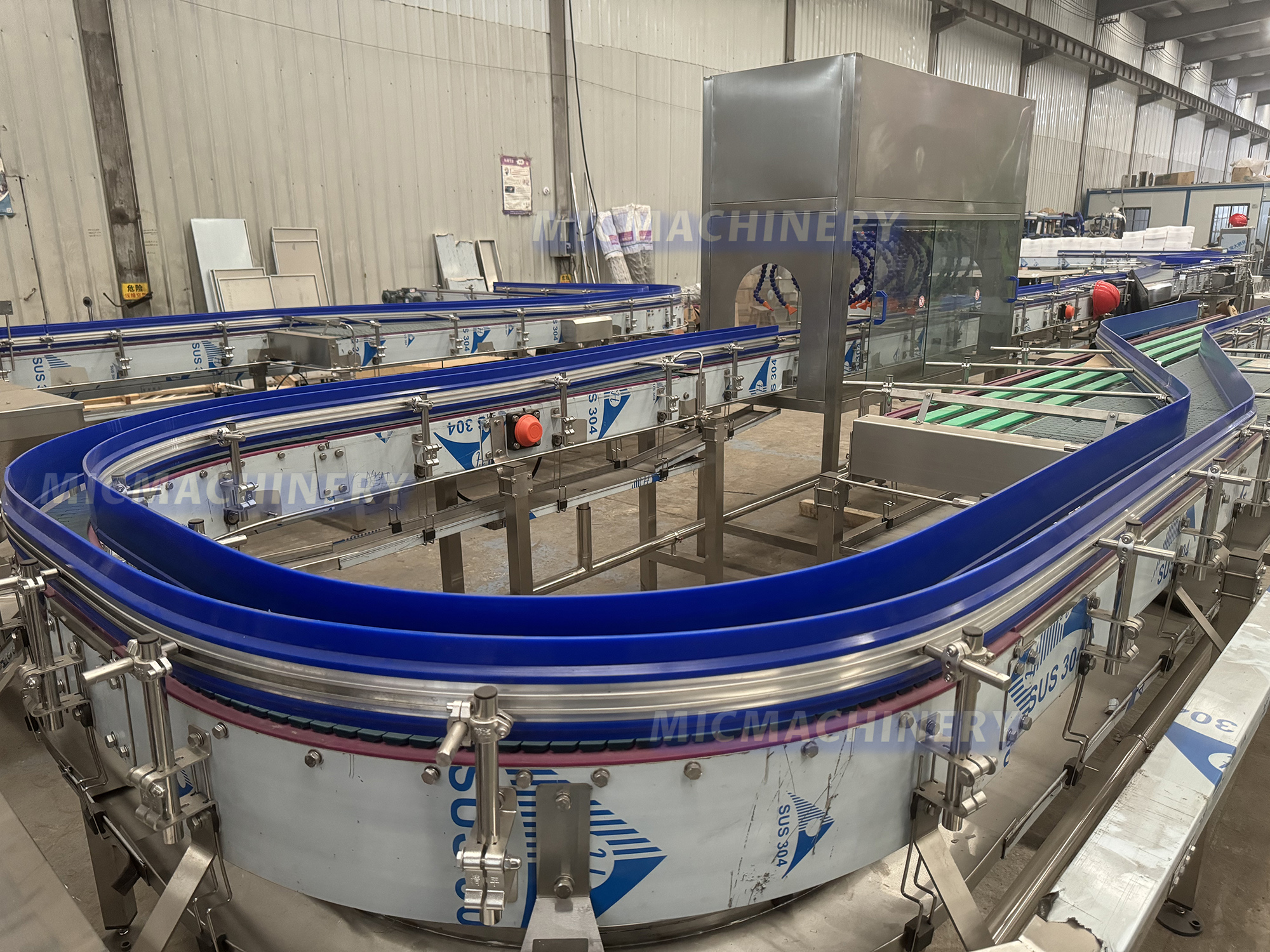

Conveyor System Optimize your Water Bottle Packing Machine with a high-speed conveyor system for smooth and efficient bottle transportation. Designed for stability and durability, it ensures seamless movement through rinsing, filling, and capping stages. Ideal for packaged drinking water machine setups, it enhances automation and boosts production efficiency. |

|

Electrical Control Panel Optimize your Water Bottle Packing Machine with a high-performance electrical control panel for precise automation and efficiency. Our advanced control systems ensure seamless operation, accurate filling, and energy savings. Designed for reliability, they enhance production stability in packaged drinking water machine setups. |

|

|

|

Capping part

- 304 stainless steel construction. No bottle no capping. Capping effect is stable and reliable |

Working Principle

1)The automatic water bottle packing machine combines rinsing, filling, and capping in a fully integrated workflow.

2)Empty bottles are transported to the rinsing station, where they are cleaned with purified water to ensure hygiene.

3)Clean bottles then proceed to the filling unit, where precise volumes of water are dispensed.

4)The plastic water bottle packing machine automatically seals bottles with caps to maintain product integrity.

5)The entire process is controlled by a PLC system, providing smooth, automated operation with minimal manual intervention.

Functional Advantages

▪ High automation improves production efficiency and reduces labor costs.

▪ Stainless steel construction meets sanitary standards and ensures durability.

▪ Adjustable for different bottle sizes and filling volumes, offering versatility.

▪ Compact footprint saves space while maintaining high output capacity.

▪ Integrated safety and fault detection systems ensure reliable and safe operation.

Applications

This drinking water bottle packing machine is ideal for bottling pure water, mineral water, and other non-carbonated beverages. It is widely used in beverage factories, water bottling plants, and food processing facilities requiring efficient and hygienic packaging solutions.

Conclusion

The MIC 40-40-10 is a dependable, precise, and efficient automatic water bottle packing solution. Mic Machinery ensures that this equipment meets high standards, delivering reliable performance for all your water bottling needs.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |