MIC Aluminum Can Labeling Machine

|

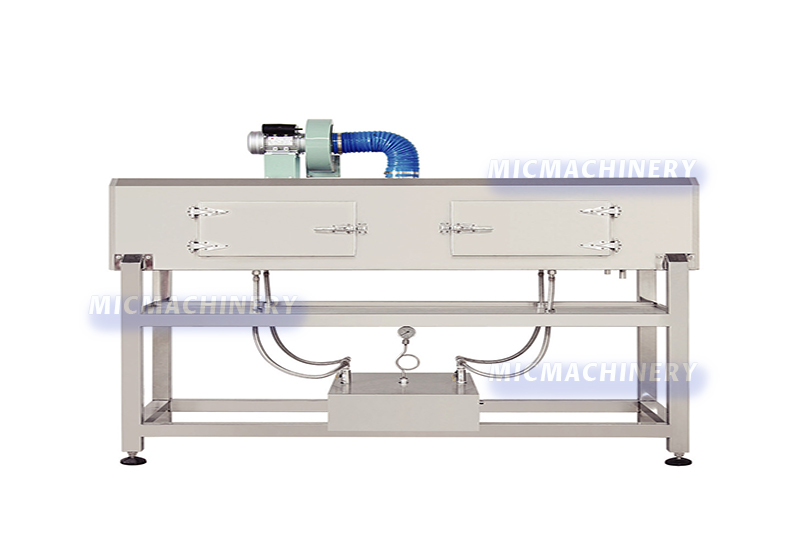

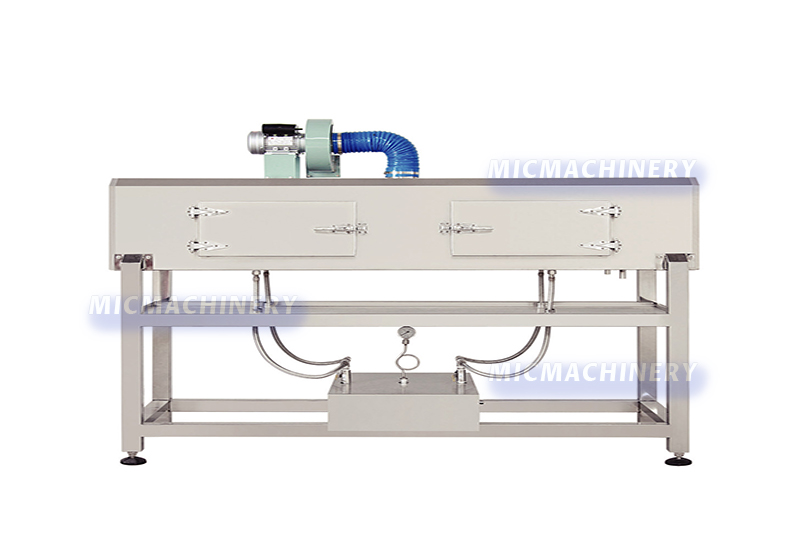

SLM-1800 Steam Shrink Tunnel 1. In the case of different and irregular round bottles, square bottles and flat bottles etc, the new-style both steam and electricity shrinking oven is easy to adjust and maintain. It has an even shrinking .2.The distribution of low-pressure steam drum and sqouting way of steam are uniform and designed with seamless tube. 3.The nozzle is divided to be adjustable three segments and the height , position and steam output of every segment can be adjusted respectively so as to gain the perfect shrinking effect. 4 .The whole machine is made of stainless steel with heat preservation, which not only saves energy, but also comply with the international safety standard. 5 .The stainless steel defrosting tray collects condense water. |

|

|

Stream Generator

The water is fed into the series of wholly automatic electrical heating generator by high pressure potential vortex pump made of copper with short water-supply time and durable service. A floating ball for liquid level is fixed in the water tank to automatically control the water inlet. Working system is all automatically controlled. After connecting the water supply and power supply for 5 minutes or so, it can output the steam continuously with a high level of working efficiency. |

Characteristics:

Manually casing the labels, and then the bottle will be passed into the shrink tunnel, and shrink tightly by steam.

Technical parameter :

Size of tunnel: 1.5*0.5*1.6m(can be customized)

Steam generator power: 18kw

Steam shrink tunnel size: 1000*500*500mm

This is the description of sleeve shrink labeling machine shrink sleeve machine price heat shrink sleeve machine shrink wrap label machine