MIC Orange Juice Production Line (600-800PCS)

MIC Orange Juice Production Line: Product Introduction

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer and supplier of high-performance juice production systems, specializing in providing businesses with state-of-the-art machinery for efficient and high-quality production. With years of experience in the field, we are committed to delivering the best solutions for our clients. Our orange juice production line is a prime example of our dedication to excellence, combining advanced technology with operational efficiency. It is designed to meet the growing demand for fresh, high-quality fruit juices in the market, offering superior performance for both small and large-scale producers.

|

|

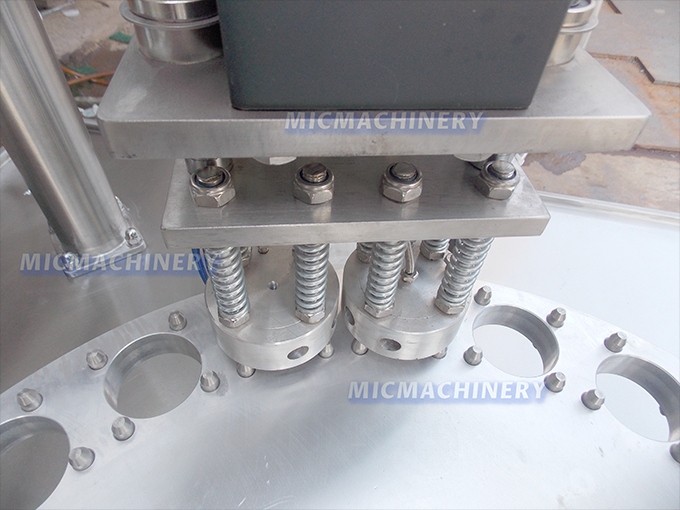

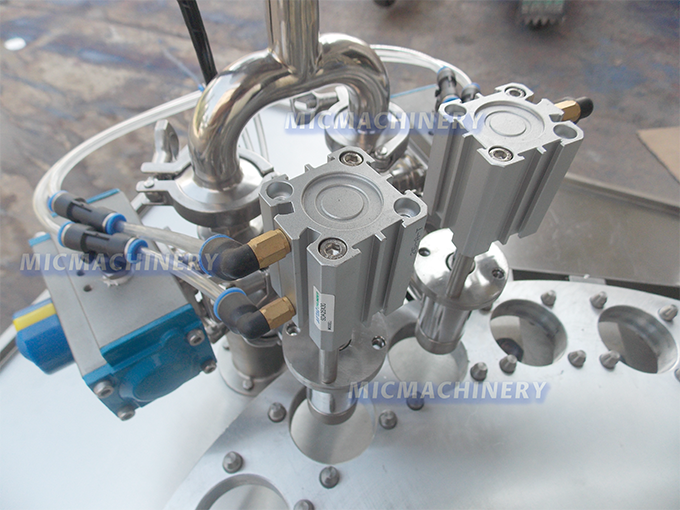

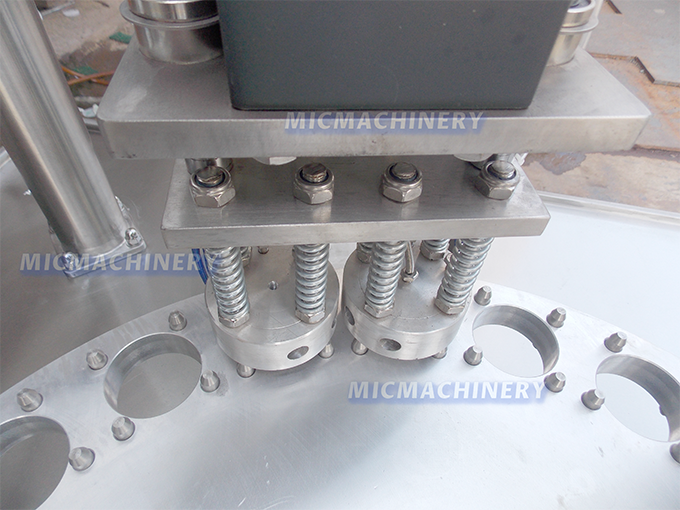

Filling station |

|

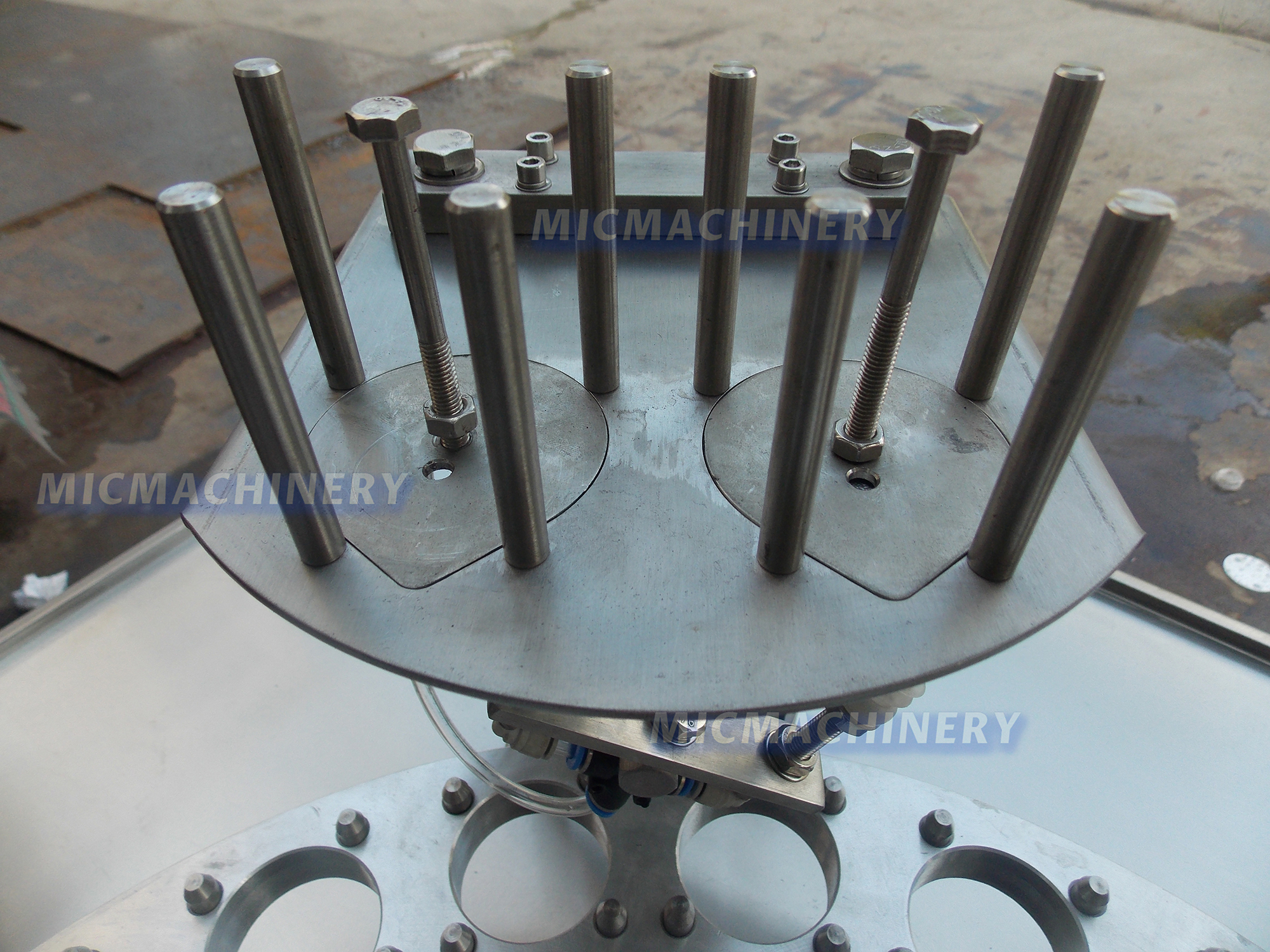

Foil loading rack

|

|

|

|

Foil sealing

|

Working Principle

The MIC orange juice production line operates through a highly efficient and automated process, ensuring the best extraction and filling processes. The line begins with the washing and cleaning of fresh oranges, followed by the extraction of juice using an advanced juicing system that maximizes juice yield while preserving flavor and nutritional value.

Once the juice is extracted, it moves to the filtration process, where any impurities or pulp are removed, ensuring a smooth, clean product. After filtration, the juice is then pasteurized to eliminate harmful microorganisms and extend shelf life. The juice is finally filled into bottles or containers using the fruit juice filling production line, ensuring consistent volume, minimal waste, and precise packaging. The entire process is automated, offering high-speed operation with minimal manual intervention, thus enhancing efficiency and reducing labor costs.

Advantages

The MIC orange juice production line offers several key advantages that make it the ideal choice for businesses looking to enter or expand within the juice production industry:

1.High Efficiency

The entire process is automated, resulting in higher productivity and less downtime. This is critical for businesses looking to meet high demand with consistent quality. The fruit juice production line can handle large volumes, offering high throughput while maintaining precision and speed.

2.Customization

Whether you’re focusing on orange juice production line or other fruit juices, our system is highly adaptable, allowing businesses to adjust their operations for different juice types. This versatility ensures that companies can cater to various market demands and preferences.

3.Quality Control

From extraction to filling, the production line is designed with precision to ensure that the end product meets the highest quality standards. The pasteurization process ensures product safety, while the filling system guarantees that each container is filled accurately, reducing product wastage and enhancing consumer satisfaction.

4.Cost-Effectiveness

By streamlining the production process, the fruit juice filling production line helps reduce overall costs, including labor, energy consumption, and waste. This cost-efficiency makes the line an attractive option for businesses seeking to maximize their profit margins.

5.Hygienic and Safe

All materials used in the production line are food-grade, meeting international hygiene standards. The entire line is designed to maintain the highest level of sanitation throughout the process, ensuring that the juice remains safe for consumption.

In conclusion, the MIC orange juice production line is a top-tier solution for companies looking to enhance their fruit juice production. It combines innovation, efficiency, and reliability, making it the perfect investment for businesses looking to scale up their operations while maintaining the highest standards of product quality.

| Diameter | 1100*1100*1600mm |

| Weight | 350KGS |

| Power | 2 KW |

| Voltage | 110V/ 60Hz 1P |

| Air pressure | 0.6-0.8Mpa |

| Capacity | 600-800 pcs/hour |

| Air consumption | 0.6m³/min |

| Heating type | electrical heated |

| Working position | 6 |

| Machine frame | SUS 304 |

| Item | Brand |

| PLC | OMRON |

| Touch Screen | WEINVIEW |

| Motor | DINGYI |

| Magnetic Valve | JELPC |

| AC Contactor | SCHNEIDER |

| Temperature Control | SIMP |

| Relay, Circuit Breaker | DELIXI |

| Divider | REP |

| Pneumatic Component | AKS |