MIC Semi Automatic Beer Sealing Machine (15CPM)

MIC Semi Automatic Beer Sealing Machine

Jiangsu MIC Machinery is a professional manufacturer of beverage and packaging machinery with decades of industry experience. We specialize in providing complete turnkey solutions, from single machines to full production lines. Our products are known for high reliability, ease of operation, and excellent after-sales support, serving clients in over 30 countries.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

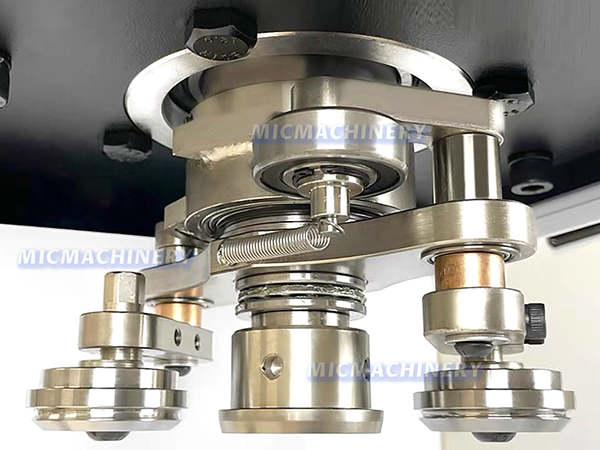

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to bottles, jars, or cans, ensuring product safety and preventing leaks or contamination. |

Equipment Introduction

The MIC Semi Automatic Beer Sealing Machine is a specialized unit designed for sealing cans filled with beer or other carbonated drinks. It is especially suitable for craft breweries and small-scale beverage plants that require reliable sealing without the need for complex automation. The machine is compact, durable, and easy to integrate into a basic beer filling line.

This machine supports a variety of aluminum can sizes, allowing quick adjustments without replacing major components. It features a user-friendly interface with button control, ensuring smooth operation even for new staff. The sealing process uses mechanical rollers to form strong, leak-proof seams that help preserve flavor and carbonation.

Thanks to its mechanical stability and precision, the semi automatic beer sealing machine is often used in pilot production, product testing, or as a backup unit in a full beer line. Its simplicity makes it ideal for businesses seeking flexibility, quality, and consistent output without the investment required for a fully automatic beer canning line.

Key Advantages

The machine offers multiple advantages that make it a preferred choice for modern beverage producers:

1.Durable Construction

Made of stainless steel for long-term use, with resistance to rust and corrosion in humid or wet environments.

2.Versatile Compatibility

Easily adjusts to fit various can heights and diameters, supporting diverse packaging needs within a beer line or customized setup.

3.Simple Operation

Operated via button control, reducing labor intensity and training time.

4.Efficient Performance

High sealing accuracy and tightness help prevent leaks and preserve flavor, critical for maintaining beer quality.

5.Cost-Effective

Offers great value for money by providing professional-level sealing without the cost or space requirements of a full beer canning line.

6.Low Maintenance

With minimal moving parts and robust mechanical design, the machine requires very little maintenance and ensures consistent performance.

Working Principle

The semi automatic beer sealing machine works through a simple two-stage sealing process. First, the can is manually placed onto the platform. The operator initiates the cycle, and the rotating head applies two rollers in sequence: one to hook the lid and the second to seal it tightly. This mechanism ensures a uniform and leak-proof seam, protecting the beverage from contamination and oxidation.

Conclusion

For small breweries and beverage producers looking for a dependable sealing solution, the MIC Semi Automatic Beer Sealing Machine is an ideal choice. It seamlessly complements your existing beer filling line by improving packaging consistency without increasing overhead. With reliable build quality, flexible configuration, and excellent sealing results, this machine is a solid investment for long-term production efficiency.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 15 cans each minute |