MIC Semi-Automatic Drink Sealing Machine (15CPM)

MIC Semi-Automatic Drink Sealing Machine

Mic Machinery is a specialized manufacturer of professional-grade beverage processing and packaging equipment. With a focus on precision and innovation, we offer comprehensive solutions for canning, bottling, and sealing in various beverage sectors. One of our flagship products, the semi-automatic drink sealing machine, is designed to support small to medium-sized businesses that require reliable, compact, and efficient sealing solutions.

|

|

Machine This compact and modern beer canning machine features a sleek white design with a transparent viewing area and an intuitive control panel. Its clean and professional appearance suits breweries and beverage businesses, ensuring functionality with aesthetic appeal. |

|

Control Panel The control panel of our beer canning machine is designed for ease of use, offering intuitive controls. |

|

|

|

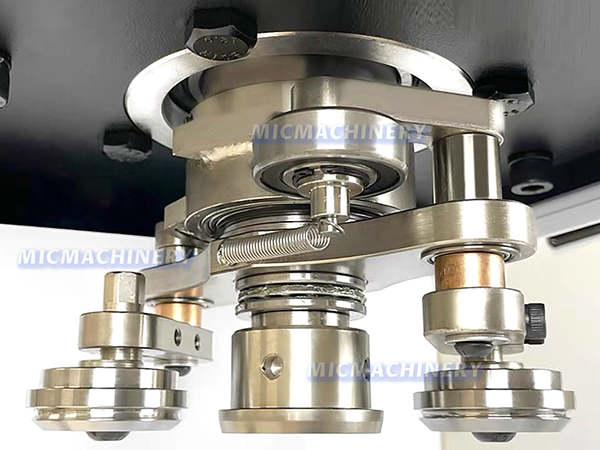

Capping Station A Capping Station is an essential part of the filling and packaging process, designed to securely apply caps to jars, or cans, ensuring product safety and preventing leaks or contamination. |

Working Principle

The MIC Semi-Automatic Drink Sealing Machine operates through a mechanical process that combines user control with automatic sealing. Here's how the system works step by step:

1)Manual Loading: Operators place filled beverage cans onto the platform.

2)Lid Placement: A lid is manually positioned on top of the can.

3)Clamping: The machine locks the can in place for accurate sealing.

4)Sealing Head Engagement: The rotary sealing head compresses and seals the lid securely.

5)Can Removal: The sealed can is unclamped and removed for labeling or packing.

This process minimizes product loss and ensures tight, professional seals that help preserve flavor and carbonation.

Functional Advantages

This semi-automatic drink sealing machine is ideal for facilities that demand efficiency without sacrificing quality. Key features and benefits include:

▪ Stainless steel construction for hygiene and durability

▪ Adjustable for different can sizes and volumes

▪ Compatible with both cold drink filling machine and drink filling machine systems

▪ Compact footprint for use in limited spaces

▪ Simple operation, low maintenance, and high sealing precision

▪ Up to 25–30 cans per minute based on operator efficiency

It is particularly effective for craft beverage producers and test-batch environments.

Applications

The MIC Semi-Automatic Drink Sealing Machine serves a variety of industries, including soft drinks, carbonated water, juices, energy drinks, and more. When paired with a drink filling machine, it forms an efficient production line. It's also compatible with cold drink filling machine setups, making it ideal for small breweries, cafés, pilot plants, and research centers. Whether you're sealing sparkling beverages or chilled flavored drinks, this equipment delivers consistent results.

Conclusion

The MIC Semi-Automatic Drink Sealing Machine is a compact, cost-effective, and durable solution for sealing operations in small to mid-scale beverage production. It integrates seamlessly with drink filling machine lines and cold drink filling machine systems, ensuring a reliable packaging workflow that maintains product quality. For beverage producers looking to streamline can sealing with confidence, Mic Machinery provides the perfect answer.

| Weight | 52kg |

| Voltage | 220V 50Hz |

| Packaging Type | CANS, Bottles |

| Dimension | 255*455*608mm |

| Motor power | 0.55KW |

| Filling speed | 15 cans each minute |