MIC Semi Automatic Glass Bottling Machine

Working Principle of Glass Bottling Machine

The MIC Semi Automatic glass bottling machine is designed to provide an efficient solution for smaller to medium-scale production lines. This machine works by using a semi-automated process that combines manual and automatic functions, offering flexibility and precision in bottling operations.

The process begins with empty glass bottles being manually placed into the machine’s filling stations. The semi automatic glass bottle filling machine uses a combination of manual labor and automated mechanisms to fill the bottles with the desired product. The filling process is controlled by a filling valve that ensures accurate and consistent amounts of liquid are dispensed into each bottle, maintaining product quality while minimizing waste.

Once the bottles are filled, the capping process is manually operated but follows an automated mechanism to securely seal the bottles. The glass bottle filling machine provides a straightforward design that allows operators to control the speed of production while maintaining quality control at each step. This semi-automatic system allows businesses to scale operations based on their needs, making it an ideal solution for smaller production runs or for companies looking to test new products before committing to full automation.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

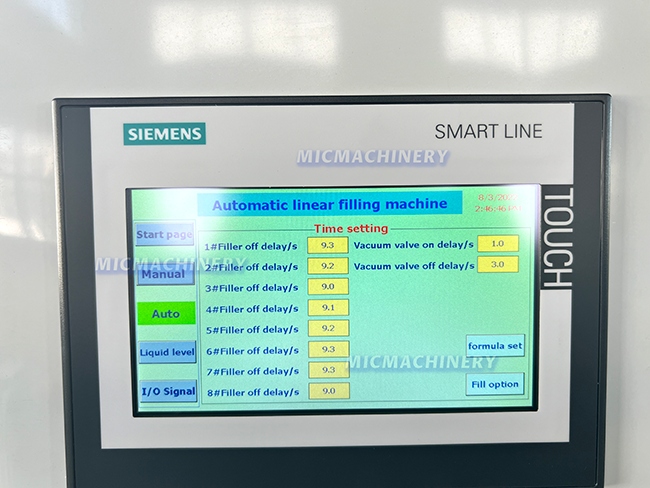

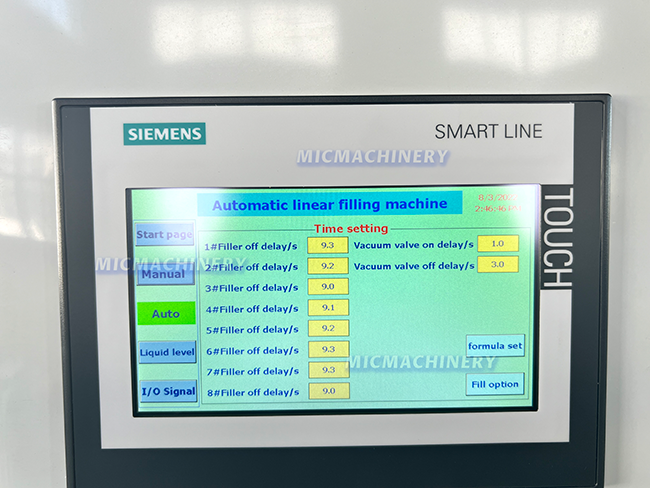

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Advantages of Glass Bottling Machine

The MIC Semi Automatic glass bottling machine offers numerous advantages that make it an excellent choice for businesses seeking efficiency, precision, and flexibility in their bottling processes:

1、Cost-Effective Solution

The semi-automatic nature of the machine makes it more affordable compared to fully automated systems. It is an ideal option for businesses with moderate production needs, as it strikes a balance between cost and productivity.

2、Flexibility in Operation

The semi automatic glass bottle filling machine allows for more manual control over the bottling process. This flexibility is particularly useful for businesses with varying production needs or different bottle sizes, as the machine can be adjusted easily for different formats.

3、High Precision and Consistency

Despite being semi-automatic, the glass bottle filling machine ensures high accuracy in filling. The advanced filling valve system guarantees precise fill levels, reducing product waste and ensuring uniformity across batches.

4、Compact and Space-Efficient

The semi automatic glass bottling machine is designed to occupy less space than fully automated systems, making it suitable for businesses with limited floor space. Its compact size does not compromise on performance, making it a reliable choice for small-to-medium production volumes.

5、Reduced Labor Costs

By automating certain parts of the process, this machine reduces the need for extensive labor while still retaining manual oversight, which helps to lower overall operational costs.

6、Ease of Maintenance

The semi-automatic design allows for easy maintenance and quick troubleshooting. The machine’s straightforward construction means that operators can identify and address any issues with minimal downtime.

7、High-Quality Construction

Built with durable materials, including stainless steel, the glass bottle filling machine is resistant to wear and corrosion, ensuring long-term reliability and performance even under demanding conditions.

8、Adaptable for Various Products

This machine can handle both carbonated and non-carbonated beverages, making it suitable for a wide range of product types. It can easily be adjusted to accommodate different types of liquids, allowing for versatility in production.

In conclusion, the MIC Semi Automatic glass bottling machine offers businesses an efficient, cost-effective, and flexible solution for glass bottle filling. Its precision, ease of use, and adaptability make it an excellent choice for businesses looking to streamline their bottling process while maintaining high-quality standards. With Jiangsu Mic Machinery’s commitment to quality and innovation, this machine provides a reliable and professional solution for small to medium-scale production lines.

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |