Semi Automatic Juice Filling Machine

Equipment Introduction of Semi-Automatic Juice Filling Machine

The semi-automatic juice filling machine is a versatile and efficient solution designed for small to medium-scale juice production lines. At Jiangsu Mic Machinery, we specialize in manufacturing high-quality filling equipment that meets the diverse needs of the beverage industry. This machine is ideal for businesses that require a balance of automation and manual control, offering flexibility and precise filling for various juice types, including fruit juices, smoothies, and flavored drinks.

Our fruit juice filling machine is engineered for speed and accuracy, providing a cost-effective solution for businesses that need to maintain high production standards without the full automation of larger systems. The machine is equipped with modern technology to ensure smooth operation, reduce waste, and maximize efficiency while keeping maintenance costs low.

Whether you’re just starting your juice production or upgrading your equipment, this juice filling machine offers outstanding performance with easy operation, making it the perfect choice for many juice manufacturers worldwide.

|

|

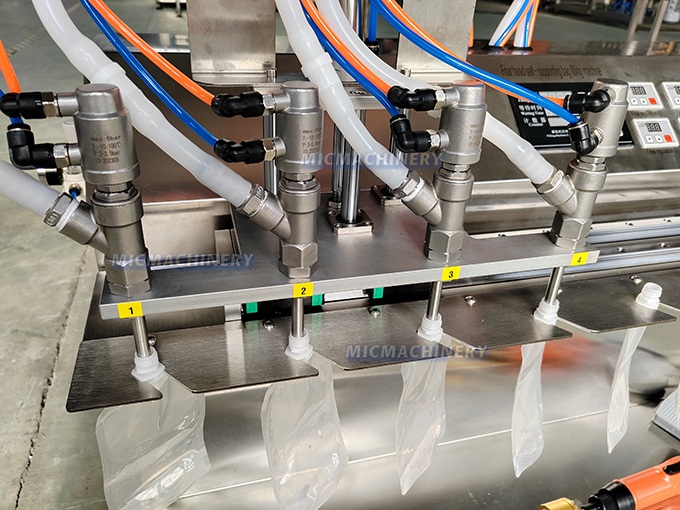

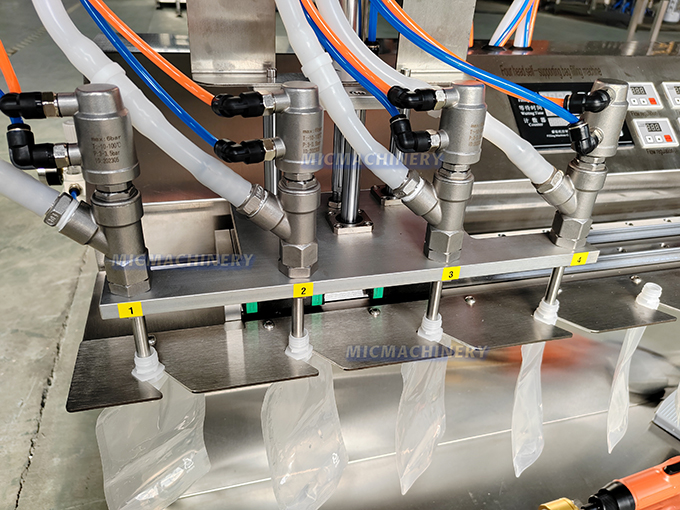

Filling tube A Filling Tube is a critical component in liquid filling machines, directing the flow of liquids into containers. It ensures smooth, accurate filling, preventing spills and optimizing production efficiency. |

|

Touch screen panel A Touch Screen Panel is an intuitive interface used to control and monitor machinery. It allows users to easily adjust settings, access real-time data, and streamline operations with a simple touch interface. |

|

|

|

Filling heads Filling Heads are essential components in automated filling systems, designed to precisely dispense liquids or powders into containers. They ensure accurate volume control, enhance efficiency, and reduce product waste.

|

Workflow of Semi-Automatic Juice Filling Machine

The semi-automatic juice filling machine follows a straightforward yet highly effective workflow that ensures a reliable and hygienic filling process

Preparation and Setup: The operator fills the juice reservoir with fresh juice, adjusts the machine’s settings for the specific bottle size, and ensures that the filling valves are clean and ready for operation.

Filling Process: Once the system is set up, the operator manually places the bottles under the filling nozzles. The machine will automatically start the filling process, ensuring accurate juice distribution. The fruit juice filling machine utilizes gravity or volumetric filling technology to achieve precise volumes for each bottle.

Capping or Sealing (Optional): After filling, the operator places caps or seals on the bottles. Some versions of the juice filling machine include integrated capping functions, while others allow for manual capping post-filling.

Quality Control and Packaging: After the bottles are filled and capped, they are checked for consistency and any leaks, ensuring quality control. The filled bottles are then ready for labeling, packaging, and distribution.

The semi-automatic nature of the machine means that it combines the precision of automation with the control that manual operation provides, allowing operators to oversee the filling process more closely while still benefiting from enhanced efficiency.

Advantages of Semi-Automatic Juice Filling Machine

1、Cost-Effective Solution

The semi-automatic juice filling machine is an affordable option for businesses that require high-quality filling without the significant investment needed for fully automatic systems. This makes it an excellent choice for small and mid-sized juice manufacturers who are looking to expand their production capacity without overwhelming their budget.

2、Flexible and Adaptable

This machine can handle a wide range of juice types, including fruit juices, concentrates, and other non-carbonated beverages. It is compatible with various bottle sizes and shapes, making it highly adaptable for businesses with diverse product offerings.

3、High Accuracy and Consistency

The fruit juice filling machine provides precise and consistent fills for each bottle, ensuring that each product meets the same standard of quality. With the ability to fine-tune the filling volume, it reduces waste and optimizes production efficiency.

4、Ease of Operation

Designed with user-friendly controls, the juice filling machine requires minimal training for operators. The intuitive interface makes it simple to adjust settings, monitor performance, and ensure that the filling process is running smoothly.

5、Reduced Labor Costs

While still offering some manual control, the semi-automatic system reduces the need for excessive labor. Operators can manage multiple tasks at once, which helps reduce staffing requirements and lowers overall labor costs.

6、Enhanced Hygiene and Safety

The machine’s design emphasizes hygiene, ensuring that the semi-automatic juice filling machine meets strict sanitary standards. With easy-to-clean components and a smooth filling process, it minimizes contamination risks, preserving the quality and safety of the juice.

7、Compact and Space-Saving

Unlike larger, fully automated systems, the semi-automatic machine has a smaller footprint, making it a great option for businesses with limited space. It can fit easily into existing production lines without requiring major adjustments.

8、Lower Maintenance Costs

With fewer mechanical parts compared to fully automatic machines, the juice filling machine requires less frequent maintenance. The simple, durable design minimizes wear and tear, helping to reduce long-term maintenance costs.

9、Scalable Production

As your business grows, the semi-automatic juice filling machine can be upgraded or integrated with other machines to increase production output. It provides the flexibility to expand your capacity gradually as demand increases.

Conclusion

The semi-automatic juice filling machine is a highly efficient and versatile solution that combines precision, affordability, and flexibility, making it the perfect choice for small to medium-scale juice production. With its ability to handle a wide variety of juice types and packaging, this machine offers an excellent balance of automation and manual control. At Jiangsu Mic Machinery, we are committed to providing high-performance filling equipment that meets the highest industry standards, ensuring that your juice production remains efficient, reliable, and cost-effective.

For more information about our juice filling machine offerings or to inquire about purchasing, please contact us today.

|

Filling heads |

6 filling heads |

|

Production speed |

90-100 pouches/min |

|

Suitable pouch |

Spout pouch, doypack |

|

Filling range |

50ml-250ml or 250ml-500ml |

|

Filling precision |

±1-2% |

|

Capping speed |

Match the speed of filling station |

|

Capping heads |

6 capping heads |

|

Voltage |

380V-50hz-3 Phase |

|

Power |

5kw |

|

Air pressure |

0.6Mpa-0.7Mpa |

|

Dimension |

3.5mx2.2m×2m |

|

Weight |

2000kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |