MIC Semi Automatic Soft Drink Bottling Machine (Speed 200-800BPH)

Company Introduction

Jiangsu Mic Machinery is a globally recognized manufacturer specializing in beverage bottling and packaging solutions. Our dedication to providing reliable and efficient machinery has earned us the trust of beverage producers worldwide. With a focus on innovation, quality, and customer satisfaction, we offer cutting-edge equipment designed to optimize production processes. The MIC semi-automatic soft drink bottling machine is one of our standout solutions, combining advanced functionality with ease of use to meet the demands of carbonated beverage manufacturers.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

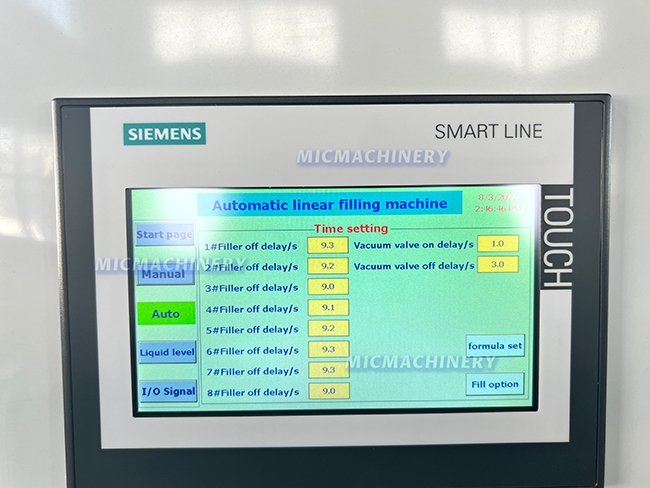

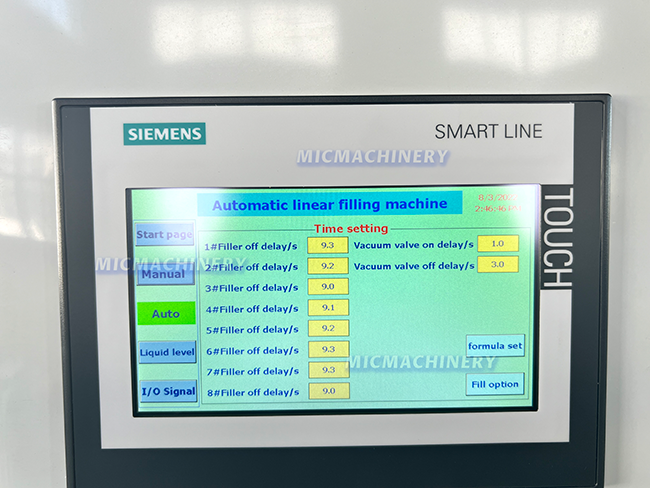

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Working Principle of Soft Drink Bottling Machine

The MIC semi-automatic soft drink bottling machine operates based on a gravity or counter-pressure filling mechanism. The process begins with the placement of bottles on the filling platform, where they are securely held in place. Once activated, the filling system carefully injects the carbonated liquid into the bottles, maintaining carbonation levels by controlling the pressure within the system.

This machine integrates seamlessly with a soft drink bottle filling system, ensuring precise liquid measurement and minimal wastage. Once the bottles are filled, they move to the capping station for sealing, completing the bottling process efficiently and consistently. The intuitive design allows operators to oversee and control each step of the operation, ensuring quality and precision.

Function

The MIC semi-automatic carbonated soft drink bottling machine is designed to serve various functions essential for soft drink production:

Rinsing: Prepares bottles for filling by ensuring they are clean and free of contaminants.

Filling: Accurately dispenses carbonated beverages into bottles, maintaining consistency in liquid levels.

Capping: Ensures airtight sealing to preserve carbonation and prevent leakage.

Foam Reduction: Special mechanisms minimize foam during the filling process, preserving the drink's quality.

Compatibility: Handles a variety of bottle sizes and shapes, providing flexibility for diverse production requirements.

This machine’s versatile design allows it to integrate with a larger soft drink bottle filling system, supporting both small and medium-scale production needs.

Advantages of Soft Drink Bottling Machine

The MIC semi-automatic carbonated soft drink bottling machine offers numerous advantages that enhance production efficiency and beverage quality:

1、High Precision

The advanced filling mechanism ensures accurate liquid measurement, reducing product wastage.

2、Cost-Effective

Semi-automatic operation strikes the perfect balance between automation and affordability, making it ideal for small to medium-sized businesses.

3、User-Friendly Design

The machine is easy to operate and maintain, with an intuitive control panel that simplifies parameter adjustments.

4、Compact Structure

Its space-saving design allows it to fit into smaller production facilities without compromising functionality.

5、Durable Construction

Built with high-grade stainless steel, the machine ensures longevity and resistance to corrosion.

6、Versatility

This soft drink bottling machine is compatible with PET, glass, and other types of bottles, accommodating various packaging preferences.

7、Carbonation Preservation

Maintains optimal pressure levels during the filling process, ensuring beverages retain their fizz and freshness.

8、Hygienic Operation

The machine meets food-grade standards, guaranteeing product safety and quality.

At Jiangsu Mic Machinery, we are committed to delivering innovative bottling solutions tailored to the needs of beverage manufacturers. The MIC semi-automatic soft drink bottling machine exemplifies our dedication to precision, efficiency, and reliability, making it an excellent choice for producing high-quality carbonated beverages.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |