MIC Small Juice Filling Machine (20-40SPM)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer specializing in the design and production of beverage filling systems for the global market. With a reputation for innovation and reliability, we offer a comprehensive range of high-quality juice filling machines to meet the needs of modern production lines. From small-scale operations to large-scale bottling systems, our products are designed to provide efficiency, precision, and durability.

Our expertise in beverage filling technology, combined with our commitment to customer satisfaction, has made us a trusted name in the industry. We focus on delivering solutions that not only enhance productivity but also ensure the highest standards of hygiene and product quality. Whether you require an automatic juice filling machine or a custom-designed system, Jiangsu Mic Machinery provides cutting-edge technology for businesses worldwide.

|

|

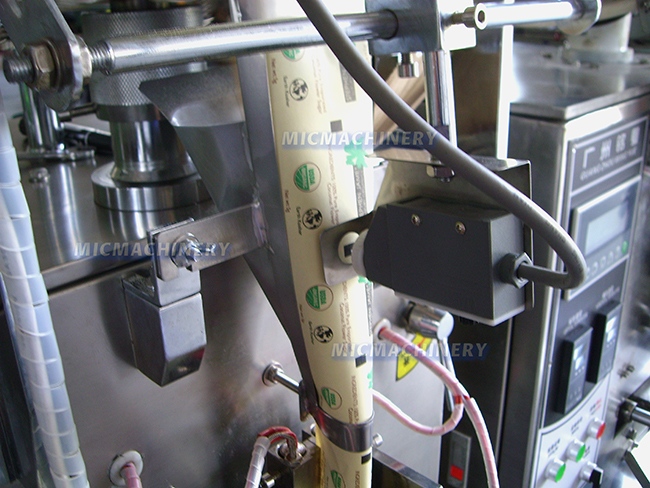

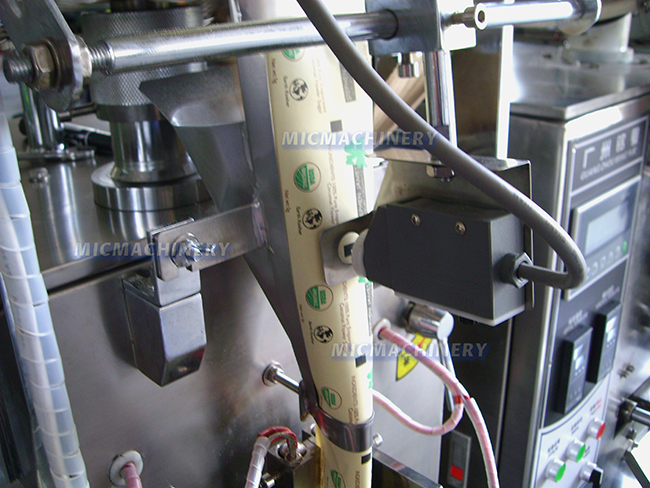

Bag Former A Bag Former is a machine used in packaging to shape and form bags from flat rollstock film. It ensures consistent bag formation, increases production speed, and maintains packaging quality in automated systems. |

|

Sensor A Sensor is a device that detects and responds to changes in the environment, such as temperature, pressure, or motion. It provides real-time data, ensuring automation systems function accurately and efficiently. |

|

|

|

Control Panel A Control Panel is an interface used to monitor and manage the operation of machines or production lines. It provides real-time control, settings adjustments, and ensures smooth, efficient operation. |

Equipment Introduction of MIC Small Juice Filling Machine (20-40BPM)

The MIC small juice filling machine (20-40BPM) is designed to meet the needs of small to medium-scale juice production lines. Capable of processing between 20 to 40 bottles per minute, this machine offers the perfect balance of high efficiency and compact design, making it an ideal solution for businesses that require moderate output while maintaining high-quality standards.

1、Filling Process

The small juice filling machine features a gravity filling system, designed for precision and efficiency. The machine ensures each bottle receives an accurate volume of juice, minimizing waste and guaranteeing consistent quality. The filling process is automated, allowing for quick adjustments to filling volumes to suit varying bottle sizes or juice types. This level of precision ensures optimal product consistency, which is essential in the competitive beverage market.

2、Automatic Operation

The automatic juice filling machine is equipped with a fully automated control system, which manages the entire filling process from start to finish. The user-friendly interface allows for easy operation and monitoring, providing real-time feedback on production speed, bottle count, and system performance. This reduces the need for manual intervention, making the process more efficient and less prone to human error.

3、Hygiene and Cleanliness

Hygiene is a critical concern in the food and beverage industry, and the MIC small juice filling machine is built with easy-to-clean components to ensure sanitary conditions. Its food-grade materials and smooth surfaces help to prevent contamination, keeping your products fresh and safe for consumers. Regular maintenance is also simplified, ensuring the equipment remains in peak operational condition.

4、Energy Efficiency

The small juice filling machine is engineered to operate with minimal energy consumption while maintaining high performance. Its efficient design reduces energy costs without sacrificing production speed, making it a cost-effective solution for businesses with limited space or lower production volume. This focus on energy efficiency ensures that your operations are both environmentally friendly and cost-effective.

5、Compact Design

Designed for businesses with space constraints, the MIC small juice filling machine has a compact footprint, which allows it to fit easily into smaller production environments. Its space-saving design does not compromise on performance, making it an excellent choice for small to medium-scale juice producers.

6、High Reliability and Durability

Built with high-quality materials, the automatic juice filling machine is designed to withstand the demands of continuous production. The durable construction ensures that the machine can handle long hours of operation, providing reliable performance over an extended period. This reduces the frequency of downtime and maintenance, allowing businesses to focus on maximizing productivity.

In conclusion, the MIC small juice filling machine (20-40BPM) is a highly efficient, reliable, and cost-effective solution for businesses that need a reliable filling system with a moderate production capacity. Whether you are a startup or an established business looking to expand your production capabilities, this machine offers the perfect blend of functionality, flexibility, and precision.

At Jiangsu Mic Machinery, we are dedicated to providing high-quality juice filling machines that are tailored to the unique needs of our customers. Our automatic juice filling machine solutions are built to last, ensuring that your business can operate efficiently while maintaining high standards of product quality. Contact us today to learn more about our products and how they can help you optimize your juice production process.

| Capcity | 20- 40 bags/min | |

| Range of measurement | 1- 100 G | |

| Bag size | (L) 20-160 (W) 20-100mm | |

| Sealing Type | Back sealing | |

| Power | 1180W | |

| Total power | 380V/50HZ 220V/50-60HZ | |

| Packing material | Paper/the polyethylene,nylon/polyethylene,tea filter paper,etc | |

| Net weight | 2 60kg | |

| Overall dimensions | (L) 800*(W) 800*(H) 1800 | |

| Sensor | Changtong (China) |

| PLC Controller | Mitsubishi/J apan |

| Stepping motor | Jiangsu huanyu |

| Main Motor | Zhaoqing Zhongbao |

| Temperature control meter module | Yuyao families meter |

| Color code photoelectric | Zhejiang both |

| Intermediate relay | Zhejiang both |

| Solid state relay | Zhaoqing Zhongbao |

| Luck film motor | Jiangsu huanyu |

| Proximity switch | Jiangsu huanyu |

| Push button switch | Japan (OMRON) |

| Power switch | Japan (OMRON) |

| Color Printer for Date | China Nanyun |

| Machine Body | SS202 , Material Control Parts SS304 |