Showing 10–18 of 10 results

Advanced Detection Machines for Quality Assurance

At Jiangsu Mic Machinery, we understand that quality control is just as crucial as production output. That’s why we offer a complete line of high-performance detection machines designed to safeguard your packaging process and product integrity. Whether you’re working with liquids, powders, pouches, bottles, or boxes, our inspection systems help ensure your final products meet the highest quality standards.

✅ What Is a Detection Machine?

|

A detection machine is an automated system used to detect abnormalities in packaging, filling, labeling, sealing, or internal pressure. These machines play a key role in food, beverage, pharmaceutical, and cosmetic industries where safety, consistency, and compliance are non-negotiable. From pouch leak detectors to liquid level detectors, these systems prevent defective goods from reaching your customers. |

🧪 Liquid Level & Pressure Inspection

|

Maintaining precise fill levels is essential in modern packaging. Our liquid level detector ensures every bottle is filled uniformly— avoiding underfilled or overfilled products that could trigger regulatory issues or customer complaints. For added safety, our capping liquid level detector combines cap presence and fill-level verification in one compact unit. For products requiring pressurized packaging, our internal pressure detector and negative pressure leak detector monitor internal conditions, identifying improper vacuum or pressure levels that may compromise shelf life or cause product failure. |

|

🛡️ Leak Detection for Pouches, Bags, and Foil Seals

|

Our pouch leak detector and bag leak detector are ideal for flexible packaging lines, detecting micro leaks, punctures, or seal failures in high-speed environments. These detectors can be seamlessly integrated after heat sealing, minimizing waste and rework. In industries using foil sealing, the aluminum foil seal leak detector is vital. This machine tests the integrity of foil-sealed containers, such as yogurt cups, juice bottles, or pharmaceutical trays, ensuring airtight protection against contamination. |

🏷️ Label & Coding Accuracy Check

|

Labeling mistakes can result in regulatory violations and brand damage. Our label coding detector checks for missing, misaligned, or incorrect labels and verifies the accuracy of printed batch codes and expiry dates. Whether using inkjet, laser, or thermal printers, this system guarantees reliable traceability and product identification. |

|

📦 Final Box and Vacuum Integrity Inspection

|

Our full box inspection machine offers a final layer of assurance by inspecting outer packaging before shipment. It can detect open flaps, incorrect dimensions, label errors, and barcode readability. For vacuum-packed products, the vacuum detection machine verifies seal quality and vacuum levels, detecting any leaks that may compromise freshness or sterility. |

🧰 Why Choose Jiangsu Mic Machinery?

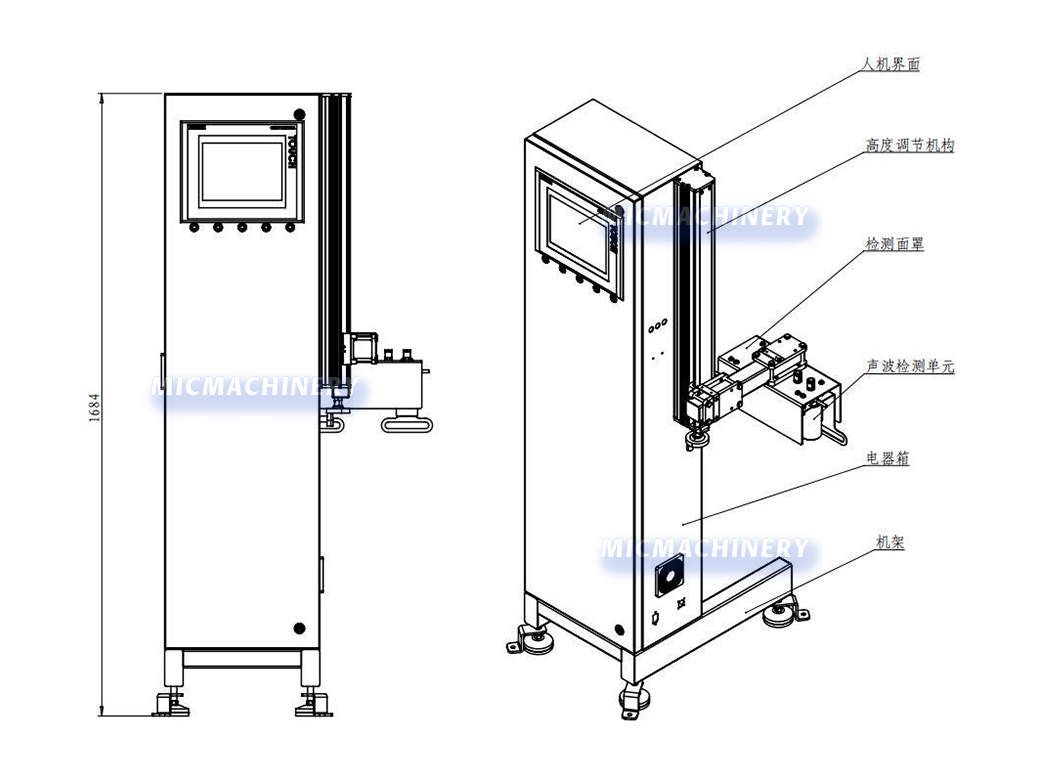

As a global leader in automated packaging equipment, Jiangsu Mic Machinery integrates detection machines with our filling, sealing, and labeling lines. Each system is engineered for accuracy, speed, and adaptability, offering you:

• Modular integration into existing lines

• Real-time feedback with rejection systems

• Touchscreen interfaces for parameter adjustments

• High-speed sensors and cameras for non-contact inspection

Our detection systems are widely used across food, beverage, chemical, and pharmaceutical sectors. Whether you need a standalone label coding detector or a complete set of leak and liquid level detectors, we offer tailored solutions for every production scenario.

🌟 Build a Smarter Line with Detection

Ensuring product integrity is no longer optional—it's a necessity. With our industry-leading detection machines, including pouch leak detectors, aluminum foil seal leak detectors, internal pressure detectors, and full box inspection machines, you can maintain compliance, reduce waste, and boost brand trust.

📧 Email: lewis@micmachinery.com

🌐 Website: www.micbeveragemachine.com

📞 WhatsApp/Phone: 0086-13961211672

Let us help you build a detection system that works flawlessly with your packaging line.