MIC-600 Automatic Flat Label Applicator

Introduction to the Instant Printing and Labeling Machine

Jiangsu Mic Machinery is excited to introduce our automatic flat label applicator, a cutting-edge solution designed to streamline the labeling and printing process for flat-surfaced products. This system combines high-speed instant printing and precise label application, making it ideal for businesses in industries like food packaging, pharmaceuticals, and cosmetics. Whether you're printing and labeling cartons, boxes, or other flat-surfaced products, the automatic flat labeling machine ensures accuracy and efficiency, boosting your production line's overall performance.

The flat surface labeling machine feature of this system ensures that labels are applied evenly and precisely to flat containers or products, ensuring a smooth and professional finish. With the automatic flat label applicator, businesses can achieve high-quality labeling with minimal manual intervention, reducing errors and increasing throughput in high-volume production environments.

|

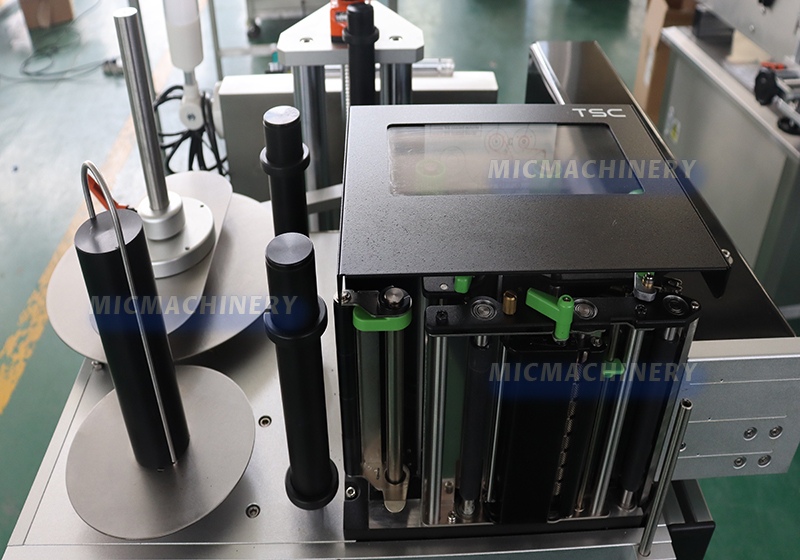

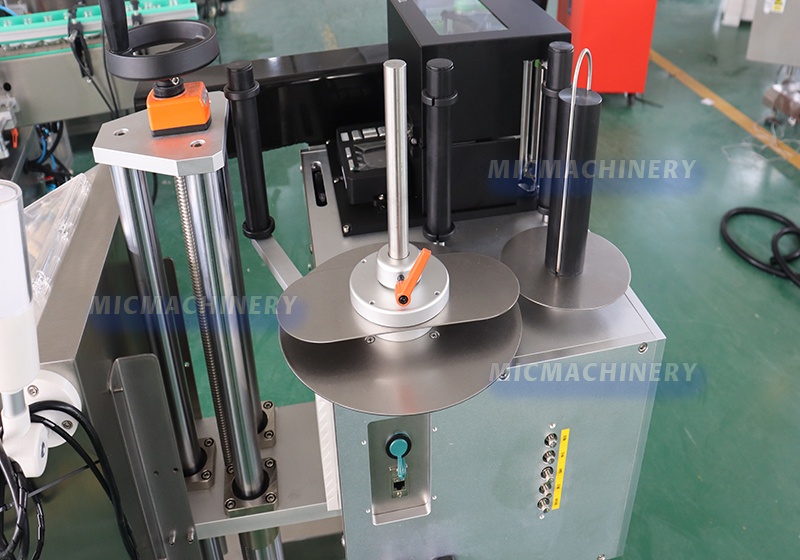

print-and-apply labeling head

The labeling head of an instant print-and-apply labeling machine integrates thermal printing and precise label application in one compact unit. As each label is printed in real time—typically with barcodes, batch numbers, or variable data—it is immediately dispensed and applied onto the product using a pneumatic or servo-driven applicator. The labeling head ensures accurate positioning and strong adhesion, even at high speeds, and is designed to handle various label sizes and surface types. Its modular structure allows for easy maintenance and seamless integration into automated packaging lines. |

|

printer

The printer in an instant print-and-apply labeling machine is typically a high-resolution thermal transfer or direct thermal unit designed to print real-time data such as barcodes, batch numbers, production dates, and product details. It receives variable data from the control system and prints each label on demand with exceptional clarity and speed. Engineered for industrial environments, the printer ensures precise alignment, quick response times, and seamless communication with labeling software. It supports multiple coding formats and materials, making it ideal for applications requiring high traceability and customization. |

|

|

printer controller

The printer controller in an instant print-and-apply labeling machine serves as the central unit that manages real-time communication between the labeling system and the printing module. It processes data from the production line or host computer—such as barcodes, batch codes, or expiration dates—and sends precise instructions to the printer for each label. With support for various coding formats and connectivity options (e.g., Ethernet, USB, serial), the printer controller ensures fast, accurate, and synchronized printing. Its intuitive interface and programmable functions allow for easy integration, quick data updates, and reliable performance in high-speed packaging environments. |

Description of the Instant Printing and Labeling Machine

Our automatic flat label applicator is designed to seamlessly apply labels to flat surfaces with speed and accuracy. The system includes an integrated instant printing feature that allows for quick printing of variable information such as batch numbers, expiration dates, and barcodes directly onto the labels. This integration of printing and labeling in one system makes it a highly efficient and cost-effective solution for manufacturers.

The automatic flat labeling machine ensures precise and secure label placement on a variety of flat-surfaced products. It can handle different label sizes and materials, providing flexibility for businesses with varying product lines. The flat surface labeling machine provides automated, high-speed labeling that reduces downtime and enhances overall production efficiency, making it the ideal solution for industries requiring fast-paced production cycles.

The system's easy-to-use interface allows operators to quickly adjust settings, ensuring that different product sizes and label formats can be processed with minimal setup time. The integration of the automatic flat label applicator with instant printing features ensures that your production line operates smoothly and efficiently, delivering high-quality results every time.

Key Features:

-

Instant printing and labeling in one seamless system with the automatic flat label applicator.

-

High-speed labeling for flat-surfaced products with the automatic flat labeling machine.

-

Precise label application with the flat surface labeling machine for consistent results.

-

Flexible design for various label sizes, materials, and flat-surfaced products.

-

User-friendly interface for easy setup and operation.

Conclusion

Jiangsu Mic Machinery’s automatic flat label applicator provides a reliable and efficient solution for businesses seeking to streamline their labeling and printing processes. Whether you need an automatic flat labeling machine for high-speed production or a flat surface labeling machine for precise label placement, our system guarantees speed, accuracy, and superior results. Enhance your production efficiency and labeling accuracy today with our advanced technology!