MIC 12-1 Beverage Canning Line (1000-2000CPH)

MIC 12-1 Beverage Canning Line

Company Introduction

At Jiangsu Mic Machinery, we are dedicated to providing innovative and high-quality solutions for the beverage industry. Our expertise in designing, manufacturing, and selling advanced beverage filling lines has helped countless businesses optimize their production processes. With years of experience and a commitment to excellence, we are a trusted name in beverage bottling and canning machinery. The MIC 12-1 Beverage Canning Line reflects our dedication to providing cutting-edge technology that meets the evolving needs of beverage manufacturers worldwide.

|

|

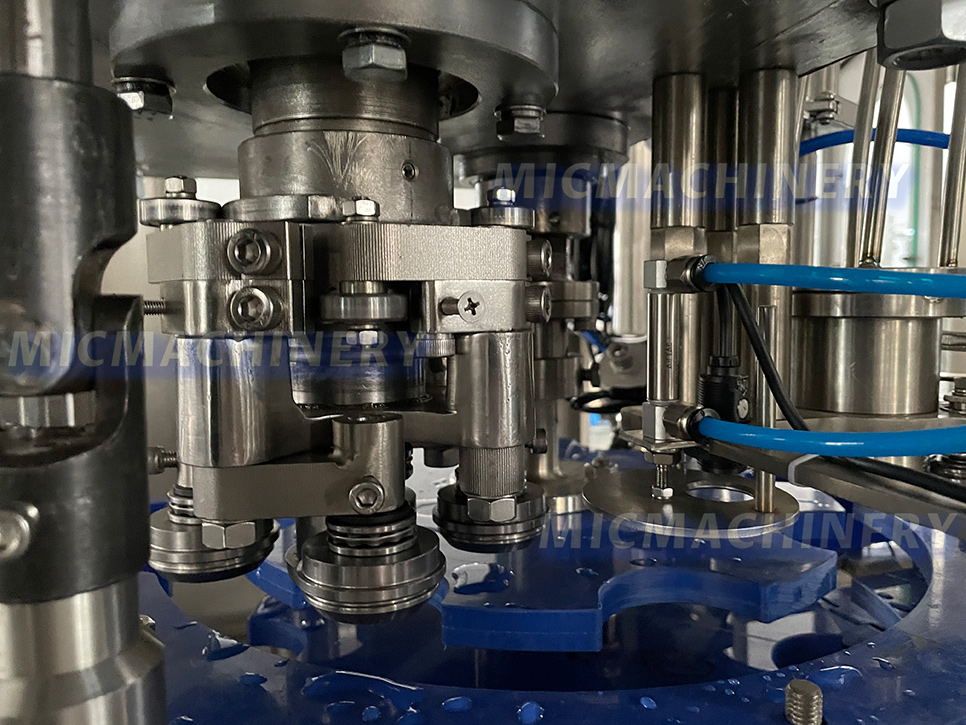

Aluminum can sealing system The aluminum can sealing system ensures airtight, secure seals for beverage and food cans. Designed for precision and reliability, it enhances product freshness and prevents leaks during storage and transport. |

|

Gravity liquid filling system The gravity liquid filling system offers a reliable, efficient solution for accurately filling beverages and liquids. Ideal for various industries, it ensures smooth operation, precision, and minimal product wastage.

|

|

|

|

Liquid nitrogen dispenser The liquid nitrogen dispenser provides precise nitrogen dosing for food and beverage packaging. It enhances product shelf life, prevents oxidation, and ensures reliable, efficient packaging operations. |

Working Principle

The MIC 12-1 Beverage Canning Line operates with advanced technology that combines precision and speed to ensure efficient canning of various beverages. The line uses an automated process, where empty cans are fed into the system, cleaned, and then filled with the beverage. The filling system utilizes a volumetric filling method that guarantees accurate filling volumes for each can. After filling, the cans are sealed and labeled, all within a seamless, automated workflow. This beverage canning line ensures high production rates and reduces human error, providing consistent and high-quality output.

Function

The MIC 12-1 Beverage Canning Line is designed to handle a wide range of beverages, from carbonated soft drinks to juices and teas. Its flexibility makes it a great addition to any beverage production line, catering to businesses looking to expand or optimize their production capacities. The system includes multiple functions such as can cleaning, filling, sealing, and labeling, making it a one-stop solution for beverage canning. Additionally, the machine can be easily customized to handle different can sizes and types, providing flexibility for manufacturers who need to adapt to varying product lines.

Advantages

1.High-Speed Production

The MIC 12-1 Beverage Canning Line is designed for high-speed operations, achieving optimal output with minimal downtime. This makes it ideal for large-scale beverage production.

2.Accuracy and Precision

The advanced filling system ensures precise volume control for each can, eliminating overfilling and underfilling issues. This ensures consistent quality in every batch produced.

3.Versatility

The canning line is adaptable to various can sizes and types, offering flexibility for different production needs. This is particularly beneficial for manufacturers with diverse product offerings.

4.Automation for Efficiency

With automated functions such as filling, capping, and labeling, the beverage canning line reduces the need for manual labor, boosting operational efficiency and reducing human error.

5.Easy Maintenance

Designed for ease of use, the MIC 12-1 Beverage Canning Line is built for simple maintenance, helping to reduce downtime and improve overall productivity. Its user-friendly interface ensures that operators can manage the system with minimal training.

6.Durable and Reliable

Constructed with high-quality materials, this canning line is built for long-term performance, providing a reliable solution for continuous production.

At Jiangsu Mic Machinery, we focus on delivering high-performance machines that improve your production processes. The MIC 12-1 Beverage Canning Line is a perfect example of our commitment to helping beverage manufacturers achieve high-quality, efficient, and cost-effective production.

MIC 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

|

Can diameter range |

Ф40-90MM |

|

Can height |

92-168MM |

|

Dimension |

1800*1300*1950mm |

|

Weight |

1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |