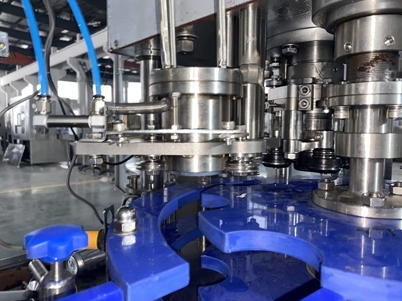

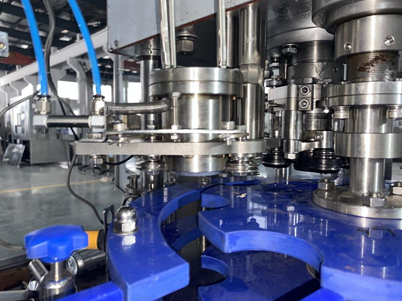

MIC 12-1 Soda Canning Machine (1000-2000CPH)

MIC 12-1 Soda Canning Machine (1000-2000 CPH): Advanced Solutions for Efficient Soda Packaging

At Jiangsu Mic Machinery, we take pride in providing innovative and reliable machinery that meets the evolving needs of the beverage industry. The MIC 12-1 soda canning machine is an exceptional product designed for medium-volume production lines, offering a robust, high-performance solution for the efficient filling and sealing of soda cans. This machine has a capacity range of 1000 to 2000 cans per hour, making it ideal for businesses seeking to enhance their production efficiency while maintaining high product quality.

Our soda can filling machine is engineered to meet the rigorous demands of modern beverage production, ensuring precision, speed, and reliability at every stage of the process. Whether you’re looking to scale your production capabilities or upgrade your existing line, the MIC 12-1 is an excellent choice for your needs.

|

|

|

|

|

Isobaric pressure / counter pressure filling system

The 12-1 isobaric counter pressure filling system is specifically designed for aluminum cans, ensuring a smooth filling process without foaming—provided the beer temperature remains below 40°F. This system maintains a standard 1.27 cm headspace, complying with can manufacturers’ requirements to accommodate product expansion during distribution. Our filling method minimizes dissolved oxygen (DO) levels in the can, preserving product quality. Built with a high-grade 304 food-grade stainless steel tank and precision buffing, the unit ensures hygiene and durability. A CIP connection can be added upon request to support automated cleaning protocols. |

Key Features and Benefits of the MIC 12-1 Soda Canning Machine

1、High-Speed Production

With a production capacity of 1000 to 2000 cans per hour, the MIC 12-1 soda canning machine is designed to handle medium-sized production volumes efficiently. It strikes the perfect balance between performance and output, ensuring that you can meet your production demands without compromising quality.

2、Precise and Consistent Filling

One of the standout features of our soda can filling machine is its precision filling mechanism. The system ensures that each can is filled to the exact level, minimizing the risk of spillage and wastage, while maintaining the integrity of the product. This accuracy is essential for carbonated beverages, where the carbonation level needs to be preserved throughout the filling process.

3、Efficient Capping and Sealing

After the cans are filled, the MIC 12-1 utilizes a state-of-the-art capping system that ensures each lid is securely and tightly sealed. This airtight sealing process is critical for soda production, as it preserves the carbonation and freshness of the beverage, extending its shelf life and enhancing the consumer experience.

4、User-Friendly Operation

The MIC 12-1 is equipped with an intuitive control panel, making it easy for operators to monitor and control the entire canning process. The system allows for quick setup, real-time tracking, and easy adjustments, significantly reducing downtime and optimizing production efficiency.

5、Automated Process for Increased Productivity

The soda canning machine for sale operates with a high level of automation, reducing the need for manual intervention and minimizing human error. This automation leads to smoother workflows, faster production rates, and a reduction in operational costs, allowing manufacturers to focus on growth rather than day-to-day operational hurdles.

6、Durable and Reliable Construction

The MIC 12-1 is built with high-quality materials designed to withstand the demands of continuous operation. Its robust construction ensures durability and longevity, making it an investment that will continue to perform for years, even in the most demanding production environments.

7、Compact and Space-Efficient

Designed with space efficiency in mind, the MIC 12-1 features a compact footprint without sacrificing its performance capabilities. This makes it an excellent option for facilities where space is limited but high production volume is still required.

8、Versatile and Adaptable

This soda can filling machine is adaptable to a wide range of can sizes and types, making it a versatile addition to any production line. Whether you're filling standard soda cans or larger beverage containers, the MIC 12-1 can handle it with ease.

9、Minimal Maintenance

With easy-to-access components and user-friendly maintenance features, the MIC 12-1 requires minimal upkeep, helping to reduce downtime and keep production running smoothly. Regular maintenance tasks are simple and quick, ensuring the machine stays in optimal condition over time.

Why Choose MIC 12-1 Soda Canning Machine for Your Production Line?

At Jiangsu Mic Machinery, we understand the importance of reliability, efficiency, and quality in beverage manufacturing. The MIC 12-1 soda canning machine for sale offers all of these qualities and more, making it an ideal choice for businesses looking to enhance their production capabilities. Its precision, efficiency, and ease of use set it apart as one of the best soda canning solutions on the market.

Whether you’re looking to increase your production capacity or improve the quality of your beverage packaging, the MIC 12-1 provides a professional-grade solution that meets the highest industry standards. It is suitable for a wide variety of soda products and can be integrated seamlessly into your existing production line.

Conclusion

The MIC 12-1 soda canning machine is a smart investment for any business involved in soda production. Its high-speed filling and capping process, combined with automated features, make it an excellent choice for medium-sized production lines. At Jiangsu Mic Machinery, we are committed to delivering top-tier solutions that help you streamline your operations and maintain the highest product quality.

For those in search of a soda canning machine for sale, the MIC 12-1 offers unmatched reliability, speed, and precision. Contact us today to learn more about how this machine can elevate your production capabilities and drive your business forward.

MIC 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

More Model And Speed Click

| Model | MIC 12-1 | MIC 18-1 | MIC 18-6 | MIC 24-6 | MIC 32-8 |

| Application | Beer, Carbonated Beverage, Gas Drinks, Cold Coffee, Sparking Water, Cider, Soda Water, Herbal Tea, Non-Carbonated Drinks And So On | ||||

| Packing Type | Aluminum Cans, Metal Cans, Tin Cans, Pet Cans Etc | ||||

| Speed | 1000-2000CPH | 1500-2500CPH | 3000-6000CPH | 4000-8000CPH | 6000-10000CPH |

| Filling Arrange | 180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) | ||||

| Power | 1.1kw | 1.5kw | 2.5kw | 3.5kw | 4.2kw |

| Size | 1.8*1.3*1.95 (M) | 1.9*1.3*1.95(M) | 2.3*1.4*1.9(M) | 2.58*1.7*1.8(M) | 2.8*1.7*1.95(M) |

| Weight | 1800KG | 2100KG | 2500KG | 3000KG | 3800(KG) |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |