MIC 12-1 Soft Drink Can Filling Machine (1000-2000CPH)

Machine is Suitable For

The MIC 12-1 soft drink can filling machine is a versatile solution designed for beverage manufacturers specializing in carbonated soft drinks. This machine is ideal for filling carbonated beverages into aluminum cans, tin cans, or other standardized containers commonly used in the beverage industry. Whether you operate a small-scale production line or a mid-sized factory, the MIC 12-1 offers an efficient and reliable solution to meet your production needs.

It is particularly suitable for a variety of carbonated beverages, such as soda, sparkling water, and flavored drinks, ensuring the integrity of carbonation and maintaining product freshness. With its compatibility with various can sizes, the machine provides flexibility for manufacturers catering to diverse market demands.

|

|

|

|

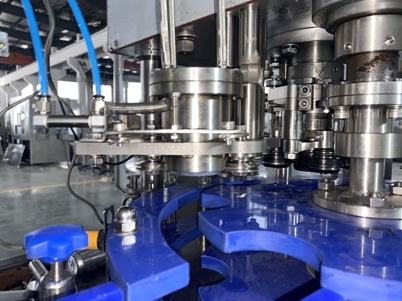

Isobaric pressure / counter pressure filling system

The 12-1 isobaric counter pressure filling system is specifically designed for aluminum cans, ensuring a smooth filling process without foaming—provided the beer temperature remains below 40°F. This system maintains a standard 1.27 cm headspace, complying with can manufacturers’ requirements to accommodate product expansion during distribution. Our filling method minimizes dissolved oxygen (DO) levels in the can, preserving product quality. Built with a high-grade 304 food-grade stainless steel tank and precision buffing, the unit ensures hygiene and durability. A CIP connection can be added upon request to support automated cleaning protocols. |

|

Machine Features

The MIC 12-1 soft drink canning machine is equipped with advanced features to ensure high efficiency, precision, and ease of operation:

Precision Filling Mechanism: The machine uses counter-pressure filling technology to ensure consistent liquid levels in each can, while preserving carbonation to maintain the drink’s quality.

Seamless Integration: The machine seamlessly integrates filling and sealing processes, reducing downtime and improving production efficiency.

Adjustable Settings: Operators can easily adjust the machine for different can sizes, allowing for quick transitions between production runs.

Stainless Steel Construction: Built with high-grade stainless steel, the machine is durable, corrosion-resistant, and meets food-grade safety standards.

Compact Design: Its space-saving design makes it suitable for small and medium-sized production facilities without compromising on performance.

Automatic Cleaning System: The integrated cleaning mechanism ensures hygiene and minimizes maintenance efforts.

User-Friendly Operation: With a simple control panel, operators can monitor and adjust the machine's parameters with ease.

Customizable Speeds: The filling speed can be adjusted to match the production line's output requirements, ensuring flexibility and efficiency.

Machine Introduction

The MIC 12-1 soft drink tin can filling machine is a state-of-the-art solution for efficiently bottling carbonated beverages in cans. This machine combines advanced technology with user-friendly features, making it an ideal choice for beverage manufacturers looking to enhance productivity while maintaining product quality.

Designed to handle the challenges of filling carbonated drinks, this soft drink canning machine ensures minimal foam formation and precise liquid filling, preserving carbonation and ensuring consistent product quality. Its robust sealing mechanism guarantees airtight closures, preventing leaks and maintaining the freshness of the beverages.

At Jiangsu Mic Machinery, we prioritize innovation, quality, and customer satisfaction. The MIC 12-1 soft drink can filling machine reflects our commitment to providing cutting-edge equipment tailored to the needs of the modern beverage industry. Whether you're looking to scale up production or enhance the quality of your canned beverages, this machine is an excellent investment for your business.

MIC 12-1 Parameters

| Power | 1.1Kw |

| Filling heads | 12piece |

| Sealing heads | 1piece |

| Production capacity |

1000-2000CPH based on 330ml |

| Filling temperature | 0-4 ℃ |

| Filling pressure | Max 5bar/0.5Mpa |

| Can diameter range | Ф40-90MM |

| Can height | 92-168MM |

| Dimension |

1800*1300*1950mm |

| Weight | 1800Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |