MIC 18-18-6 Auto Water Bottle Filler (5000-8000BPH)

Company Introduction

Jiangsu Mic Machinery is a trusted leader in the manufacturing of high-quality water filling bottle machines. With years of industry experience, we are known for providing reliable and efficient solutions to water bottling businesses worldwide. Our commitment to technological innovation ensures that each automatic water bottle filling machine we produce meets the highest standards of precision, reliability, and durability. Our auto water bottle filler machines are engineered to deliver exceptional performance in large-scale production settings, optimizing your operations for both efficiency and cost-effectiveness.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

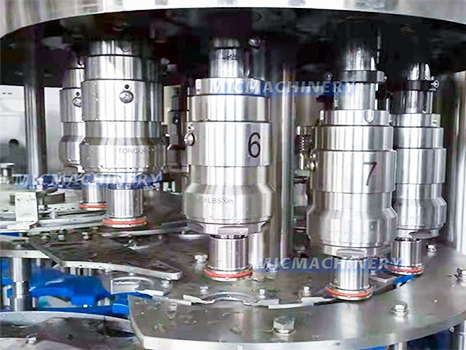

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Features

· The auto water bottle filler boasts a fully automated filling process, reducing the need for manual intervention and increasing operational efficiency.

· It uses a gravity filling system for accurate and consistent bottle filling, ensuring that each bottle receives the correct amount of liquid without waste.

· Designed to fill a wide range of bottle sizes, the water filling bottle machine can be easily adjusted to accommodate different formats, making it ideal for varied production needs.

· The automatic water bottle filling machine features high-speed capabilities, with production rates of 5000 to 8000 bottles per hour, ensuring maximum throughput for large-scale bottling operations.

· It is equipped with a reliable rinsing, filling, and capping system, enhancing overall hygiene and reducing the risk of contamination.

· The machine is constructed with high-quality materials for long-lasting performance, ensuring reduced maintenance costs over time.

· Easy-to-use controls allow operators to monitor and adjust machine settings effortlessly, streamlining the workflow and ensuring seamless production.

Advantages

1、High-Speed Production

The auto water bottle filler provides a fast and efficient filling process, meeting the needs of large-scale bottling operations with speeds ranging from 5000 to 8000 bottles per hour.

2、Automation for Reduced Labor Costs

Fully automated, the automatic water bottle filling machine eliminates the need for manual labor, reducing overall operational costs and improving workforce efficiency.

3、Precision and Consistency

The gravity filling system ensures precise and consistent filling, minimizing water wastage and ensuring the quality of each bottle.

4、Flexible Bottle Compatibility

With adjustable features, the water filling bottle machine can handle various bottle sizes and shapes, offering flexibility for different packaging requirements.

5、Reliable and Durable Construction

Built with high-quality materials, the machine ensures long-term reliability and reduced downtime, leading to cost savings in maintenance.

6、Hygienic Operation

The integrated rinsing, filling, and capping systems promote sanitary conditions, reducing the risk of contamination.

7、User-Friendly Interface

Operators can easily control and monitor the entire process through the intuitive control panel, enhancing convenience and minimizing human error.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |