MIC 18-18-6 Water Filling Line (5000-8000BPH)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer of high-quality filling and packaging equipment tailored for the beverage industry. With years of industry expertise, we specialize in offering efficient, reliable, and innovative machinery designed to optimize production processes. Our products, including advanced water bottling lines and water filling lines, are engineered to meet the specific needs of customers globally. We take pride in delivering cutting-edge technology and top-tier solutions that improve operational efficiency, reduce costs, and enhance product quality. Whether you're bottling water or other beverages, Jiangsu Mic Machinery provides scalable solutions that empower businesses to succeed in the competitive beverage market.

|

|

Bottle Washing Machine The Bottle Washing Machine effectively cleans bottles before filling, removing dirt, debris, and residues. It ensures hygienic conditions for bottling operations, improving product quality and operational efficiency in high-speed production lines. |

|

Cap Screwing Machine The Cap Screwing Machine efficiently places and tightens caps onto bottles during the bottling process. It ensures secure sealing, preventing leaks and contamination, and enhances productivity in high-speed packaging operations. |

|

|

|

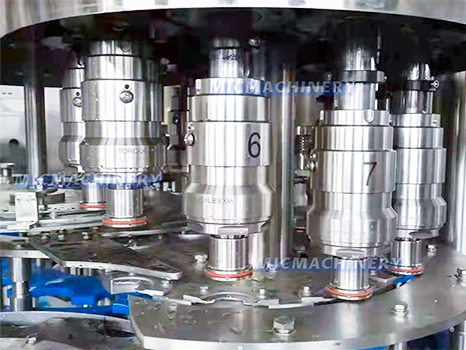

Filling System The Filling System is designed to accurately fill bottles with liquids, ensuring precise volume control and minimizing waste. It supports high-speed operations, improving efficiency and consistency in bottling lines. |

Working Principle

The MIC 18-18-6 Water Filling Line is designed to automate and optimize the entire water filling process. From rinsing the bottles to packaging the final product, this advanced water filling production line ensures efficient, high-speed operation, with precise control at every stage. The key features of the working principle are:

1)Bottle Rinsing: The process begins with the automatic rinsing of bottles, ensuring that each bottle is free from contaminants before it is filled. This step guarantees product safety and hygiene.

2)Filling Process: The water filling line uses advanced volumetric filling technology to dispense an exact amount of water into each bottle, ensuring consistency and minimizing waste.

3)Capping: After filling, bottles are automatically sealed with caps. The capping process is fully automated, ensuring that the cap is securely placed, preventing leakage and ensuring product integrity.

4)Labeling: Following the capping process, the bottles are sent through an automatic labeling system that applies labels with high precision. This step is crucial for branding and marketing, as well as regulatory compliance.

5)Packaging: The final step involves automatic packaging, where filled, capped, and labeled bottles are grouped into cartons or other packaging materials, ready for shipment.

Advantages

1.High-Speed Production

The water bottling line is designed for high-capacity output, making it suitable for large-scale production needs. It offers excellent efficiency, increasing production speed while maintaining consistent quality.

2.Precise Filling

The water filling line features advanced filling technology that ensures accurate filling, minimizing waste and maximizing efficiency. This is crucial for ensuring product quality while reducing costs.

3.Automation

The system is highly automated, reducing the need for manual labor and increasing overall productivity. The automation also minimizes the risk of human error, ensuring that each step of the process is executed flawlessly.

4.Energy-Efficient

Designed with energy-saving features, the water filling production line helps businesses reduce operational costs while maintaining high productivity. The energy-efficient design supports a more sustainable production process.

5.Minimal Maintenance

Built with durable materials and engineered for reliability, this water filling line requires minimal maintenance, resulting in less downtime and lower maintenance costs. This increases the overall longevity of the equipment.

6.Flexibility and Scalability

The water bottling line can be easily adapted to accommodate varying production volumes. Whether your production requirements increase or decrease, the system offers flexibility, allowing businesses to scale their operations as needed.

7.Compact and Space-Saving

The design of the water filling production line is compact, making it suitable for facilities with limited space. Despite its compact size, it offers robust performance and high output.

In conclusion, the MIC 18-18-6 Water Filling Line is an ideal solution for businesses looking to optimize their water bottling process. With its advanced technology, precision filling, automation, and efficiency, this line delivers a comprehensive solution for high-speed, cost-effective water production. Whether you're scaling up production or optimizing your existing operations, this line offers the reliability and performance needed for success.

|

Model |

|||

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |