MIC 18-6 Cooking Oil Filling Machine (3000-6000BPH)

Company Introduction

At Jiangsu Mic Machinery, we specialize in providing state-of-the-art packaging and filling solutions for the food and beverage industry. With years of expertise, we are dedicated to delivering machines that enhance operational efficiency, product quality, and production capacity. Our MIC 18-6 cooking oil filling machine is a perfect example of our commitment to innovation and precision. Designed for high-volume production, it offers reliable performance for filling various edible oils, including mustard oil, olive oil, and vegetable oils. Whether you're operating a small-scale business or a large manufacturing facility, this machine ensures consistent, high-quality results.

|

|

|

|

Plastic cap screwing system

In the plastic cap screwing system for plastic bottle oil filling, the motor drives the main shaft through a transmission device, enabling the turntable to rotate smoothly. Since the central gear remains fixed, the capping heads rotate as their gears engage with the stationary gear. During operation, caps are supplied automatically through the cap feeding chute and guide rail. Bottles arriving under the capping head will receive a cap, while no bottle means no cap is released. As the capping head moves downward under cam control, the cap is pressed and screwed tightly onto the bottle. Finally, the bottles are guided forward by the star wheel for smooth delivery. |

|

|

|

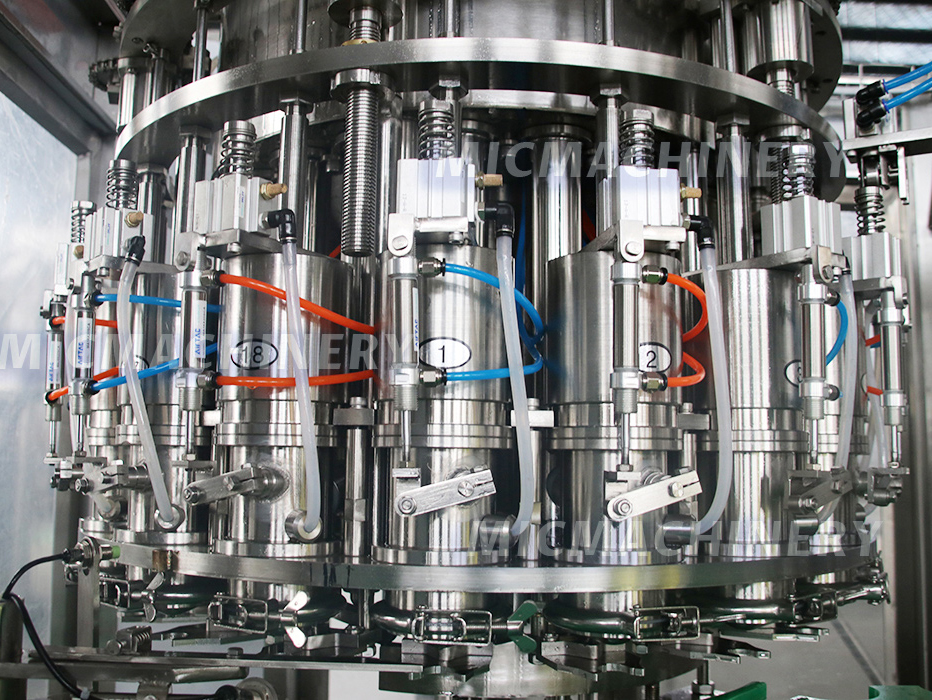

Volumetric type quantitative filling system

The volumetric type quantitative filling system for plastic bottle oil filling adopts a non-contact measuring method to ensure high accuracy and hygiene. When the measuring cup control valve opens, oil flows into the measuring cup based on the preset volume. Bottles are precisely positioned under the filling valves through the conveyor, screw, and star wheel. Once the required volume is reached, the time control system closes the measuring cup valve, guaranteeing consistent filling. To prevent dripping, a cylinder blows any residual oil from the valve outlet into the bottle, leaving a clean finish. The filled bottles are then smoothly transferred to the capping unit for sealing. |

Working Principle of the Oil Filling Machine

The MIC 18-6 cooking oil filling machine is built to streamline the filling process with maximum accuracy. Below are the key steps involved in its operation:

1)Volumetric Filling System

The filling process is governed by an advanced volumetric system, ensuring each bottle is filled to the exact volume required. A precise amount of oil is measured and dispensed into each container, whether you're filling mustard oil or other edible oils. This system ensures minimal overfilling or underfilling, which helps reduce waste and increase cost-effectiveness.

2)Automated Control System

The machine uses an automatic oil filling machine system to carry out the entire filling operation. The automated process starts when the bottle is positioned under the nozzle, and the filling cycle begins immediately. Once the required amount of oil is dispensed, the system automatically stops, reducing the risk of errors and improving the efficiency of production. This automation minimizes the need for human intervention, which reduces labor costs and increases production consistency.

3)Adjustable Nozzle and Speed

The MIC 18-6 cooking oil filling machine is equipped with an adjustable filling nozzle that can easily accommodate different bottle sizes and shapes. The machine’s high-speed capability, filling between 3000-6000 bottles per hour, ensures that production meets high-demand requirements. Additionally, the speed and volume can be easily adjusted via a user-friendly interface, offering flexibility for various production needs, including different types of oils like mustard oil and olive oil.

Advantages of the Oil Filling Machine

The MIC 18-6 automatic oil filling machine offers several key advantages that make it a reliable choice for high-efficiency production lines:

1、High-Speed Efficiency

With the ability to fill 3000-6000 bottles per hour, the machine supports large-scale operations, ensuring that your production meets high demand while maintaining accuracy and consistency.

2、Precision Filling

The volumetric system ensures that every bottle is filled to the exact volume required, which helps minimize waste and improve packaging accuracy. This is especially important in industries where consistency is key, such as mustard oil production.

3、Versatility for Different Oils

This machine is ideal for a wide range of edible oils, from mustard oil to olive oil and vegetable oils, making it highly versatile and adaptable to different production needs.

4、Cost-Effective and Labor-Saving

By automating the filling process, the MIC 18-6 reduces labor costs and human error, improving both efficiency and safety. The machine’s easy integration into existing production lines ensures a smooth transition and faster setup.

5、Easy Maintenance and Durability

Built with durable materials, the MIC 18-6 is designed to withstand the rigors of high-speed production. Its modular design ensures that maintenance is simple and fast, minimizing downtime and maximizing productivity.

6、Hygienic Design

The machine features a hygienic filling system that ensures no contamination during the filling process. This is crucial for industries dealing with food products, ensuring that every bottle of oil is safe for consumption.

The MIC 18-6 cooking oil filling machine represents the pinnacle of efficiency and reliability in the edible oil filling sector. With its precision filling technology, automation, and adaptability, it offers the ideal solution for businesses aiming to increase production capacity, reduce waste, and maintain product quality. At Jiangsu Mic Machinery, we are dedicated to providing advanced machinery that helps businesses stay ahead in an increasingly competitive market.

|

Power |

3Kw |

|

Filling heads |

18piece |

|

Sealing heads |

6piece |

|

Filling volume range |

0.5-2L |

|

Production capacity |

3000-6000CPH based on 500ml |

|

Filling temperature |

room temperature |

|

Bottle diameter range |

Ф60-120MM |

|

Bottle height |

180-380MM |

|

Air pressure |

0.6-0.8Mpa |

|

Air consumption |

0.8-1.0m³/min |

|

Dimension |

2400×1400×2500mmm |

|

Weight |

2500Kg |

|

Name |

Brand |

|

Touch screen |

Siemens (Germany) |

|

Buttons |

Schneider (France) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Germany) |

|

Frequency changer |

Schneider (France) |

|

Breaker |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |