MIC 18-6 Edible Oil Production Line (3000-6000BPH)

MIC 18-6 Edible Oil Production Line

Company Introduction:

Jiangsu Mic Machinery is a leading manufacturer specializing in the development and production of advanced filling and packaging machinery. With years of experience and a strong commitment to quality and innovation, our company provides high-efficiency systems tailored to meet the needs of industries such as food and beverage, chemicals, pharmaceuticals, and cosmetics. As a trusted supplier, we offer a range of products, from edible oil production line equipment to high-speed filling machines, ensuring customers have access to state-of-the-art machinery that enhances production processes.

Our edible oil production line is designed to meet the growing demand for high-quality edible oils. With a focus on innovation, performance, and cost-effectiveness, we aim to provide solutions that meet the diverse needs of edible oil manufacturers worldwide.

|

|

Liquid nitrogen dosing system The Liquid Nitrogen Dosing System delivers precise nitrogen doses to enhance product shelf life and packaging stability. Ideal for food, beverage, and pharmaceutical industries, it minimizes oxygen, reduces waste, and strengthens containers. Its automated design ensures efficiency and consistent dosing for high-speed production lines. |

|

Plastic bottle capper The Plastic Bottle Capper ensures secure and efficient capping for various bottle types and sizes. Equipped with adjustable torque settings, it delivers precise sealing, preventing leaks and contamination. Ideal for high-speed production, this automated system boosts efficiency, consistency, and reliability in packaging operations. |

|

|

|

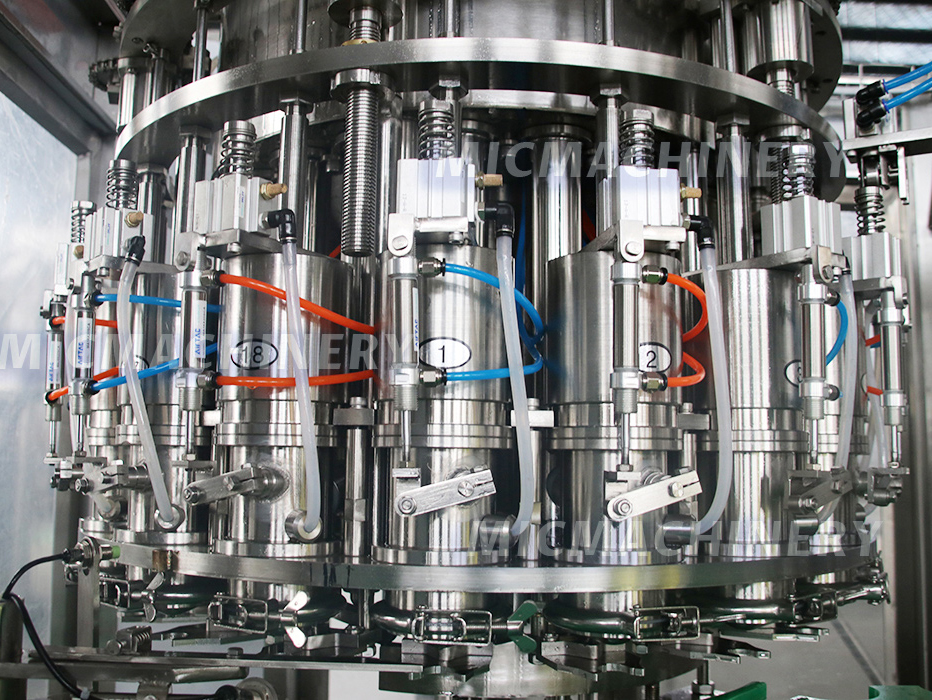

Volumetric liquid filling system The Volumetric Liquid Filling System ensures accurate and consistent filling of liquids across various container sizes. Using advanced volumetric technology, it reduces product waste and maintains precision. Ideal for food, beverage, and chemical industries, it enhances efficiency and ensures reliable performance for high-speed production lines. |

Working Principle:

The MIC 18-6 Edible Oil Production Line is designed to streamline the production of various edible oils, including sunflower oil, soybean oil, olive oil, and more. This line integrates multiple stages of the production process, from raw material handling to filling and packaging, ensuring a seamless and highly efficient production cycle.

1)Oil Extraction: The process begins with oil extraction from the raw seeds or fruits, which can be done using mechanical pressing or solvent extraction. This ensures a high yield of pure oil while maintaining the quality of the oil.

2)Filtration and Purification: After extraction, the oil undergoes filtration to remove impurities, such as solid particles or residual solvents. This step ensures that the final product is clear and free of contaminants.

3)Degumming and Deacidification: The next stage involves degumming, which removes phospholipids and other undesirable substances from the oil. The oil is then deacidified to reduce the level of free fatty acids, improving the quality and shelf life of the edible oil.

4)Refining: The oil is refined using a series of steps, including decolorization, deodorization, and winterization, to further purify it. The result is a high-quality, stable edible oil suitable for bottling and consumption.

5)Filling and Packaging: Finally, the refined oil is passed through the edible oil filling line for precise and efficient filling into various packaging sizes. The automated filling system ensures accuracy, reducing waste and maintaining consistent quality across batches.

The cooking oil production line allows for easy switching between different oil types and container sizes, making it a versatile solution for businesses with diverse product offerings. With automated control systems and user-friendly interfaces, this line reduces labor costs and improves operational efficiency.

Advantages:

1.High Efficiency: The edible oil production line is designed for maximum productivity, allowing for continuous operation with minimal downtime. This ensures that manufacturers can meet growing market demands while maintaining consistent product quality.

2.Precise Filling: The edible oil filling line is equipped with advanced filling technologies that provide precise volume control, reducing overfilling and ensuring optimal use of materials. This leads to lower costs and better product consistency.

3.Versatility: The line is capable of handling various types of edible oils, including refined oils, cold-pressed oils, and blended oils. Additionally, it supports a wide range of container sizes, from small bottles to large drums, giving manufacturers the flexibility to cater to different market segments.

4.Advanced Technology: Our cooking oil production line utilizes the latest technology in filtration, refining, and filling, ensuring that each stage of the production process adheres to the highest standards of quality and efficiency. The system is equipped with real-time monitoring, ensuring operational consistency and ease of maintenance.

5.Energy Saving: The equipment is designed with energy efficiency in mind, utilizing optimized heating, cooling, and power-saving technologies that help reduce energy consumption, thereby lowering overall production costs.

6.Automated Control: The entire line operates under automated control, reducing the need for manual intervention. This not only minimizes labor costs but also enhances safety and reduces human error during production.

7.Customizable Solutions: The MIC 18-6 Edible Oil Production Line is highly customizable, allowing businesses to adapt the line to their specific needs. Whether you're processing small batches or large-scale production runs, this system is adaptable and scalable to meet various production volumes.

Conclusion:

The MIC 18-6 Edible Oil Production Line offers a comprehensive solution for manufacturers looking to produce high-quality edible oils efficiently. From extraction to final filling, the system integrates advanced technologies that streamline the entire production process, ensuring superior quality and maximum yield. With its flexible design, precise filling capabilities, and energy-saving features, this line is an excellent investment for companies looking to scale their production while maintaining product consistency. Trust Jiangsu Mic Machinery to provide you with the tools you need to succeed in the competitive edible oil market.

|

Power |

3Kw |

|

Filling heads |

18piece |

|

Sealing heads |

6piece |

|

Filling volume range |

0.5-2L |

|

Production capacity |

3000-6000CPH based on 500ml |

|

Filling temperature |

room temperature |

|

Bottle diameter range |

Ф60-120MM |

|

Bottle height |

180-380MM |

|

Air pressure |

0.6-0.8Mpa |

|

Air consumption |

0.8-1.0m³/min |

|

Dimension |

2400×1400×2500mmm |

|

Weight |

2500Kg |

|

Name |

Brand |

|

Touch screen |

Siemens (Germany) |

|

Buttons |

Schneider (France) |

|

AC Contactor |

Schneider (France) |

|

PLC |

Mitsubishi (Japan) / Siemens (Germany) |

|

Frequency changer |

Schneider (France) |

|

Breaker |

Schneider (France) |

|

Air cylinder |

AirTAC (China) / FESTO (Optional) |

|

Solenoid valve |

AirTAC (China) / FESTO (Optional) |

|

Relay |

Omron (Japan) / Schneider (France) |

|

photoelectric sensor |

Autonics (Korea) / Omron (Optional) |

|

Proximity switch |

Autonics / Omron (Optional) |