MIC 24-24-8 Fully Automatic Water Bottle Filling Machine

MIC 24-24-8 Fully Automatic Water Bottle Filling Machine

Mic Machinery is a renowned name among water bottle filling machine manufacturers, committed to delivering innovative and reliable solutions for beverage production. Our expertise in designing high-performance equipment makes us a preferred choice for clients seeking advanced bottling technology.

|

Control Panel The Control Panel with Water Filling Machine offers precise control over the filling process. With an intuitive interface, it ensures accurate volume measurement, efficient operation, and seamless automation for water bottling. |

|

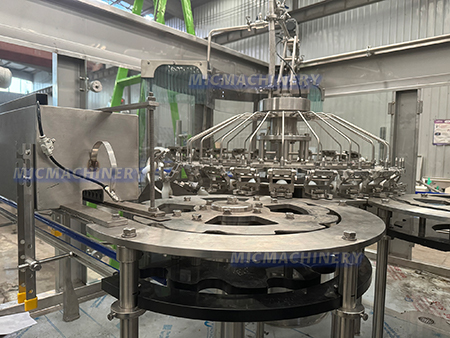

Filling Head The Filling Head with Water Filling Machine is designed to ensure precise and consistent filling of water bottles. Equipped with advanced technology, it minimizes spillage and ensures accurate volume measurement for each bottle. Ideal for high-speed, automated water bottling processes, it enhances efficiency and reduces downtime. |

|

Working Principle

1)The fully automatic water bottle filling machine completes rinsing, filling, and capping in a continuous, synchronized process.

2)Bottles enter the rinsing station where impurities are removed using purified water spray.

3)Clean bottles are transferred to the filling section where water is dispensed precisely by a volumetric filling system.

4)The automatic water bottle filler then caps the bottles securely, ensuring hygiene and product integrity.

5)The entire process is controlled by an intelligent PLC system for smooth and efficient operation.

Functional Advantages

▪ High automation reduces labor needs and increases production speed.

▪ Durable stainless steel construction ensures compliance with sanitary standards.

▪ Flexible adjustment supports various bottle sizes and filling volumes.

▪ User-friendly interface simplifies machine operation and maintenance.

▪ Compact footprint saves factory space while maintaining high output efficiency.

Applications

This fully automatic water bottle filling machine is ideal for bottling pure water, mineral water, and other still beverages. It is suitable for small to medium-sized bottling plants, beverage factories, and food processing companies seeking reliable and efficient water bottling equipment.

Conclusion

Mic Machinery’s MIC 24-24-8 offers a robust, precise, and efficient solution for modern water bottling needs. As one of the leading water bottle filling machine manufacturers, we provide an automatic water bottle filler that delivers exceptional performance and durability to meet your production demands.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |