MIC 40-40-10 Automatic Water Bottle Filler

MIC 40-40-10 Automatic Water Bottle Filler

Mic Machinery is a trusted manufacturer specializing in liquid packaging systems. With a strong reputation among water bottle filling machine suppliers, we focus on delivering high-efficiency bottling solutions that combine intelligent design with robust performance. Our machines are widely used in beverage, food, and pharmaceutical industries around the world.

|

|

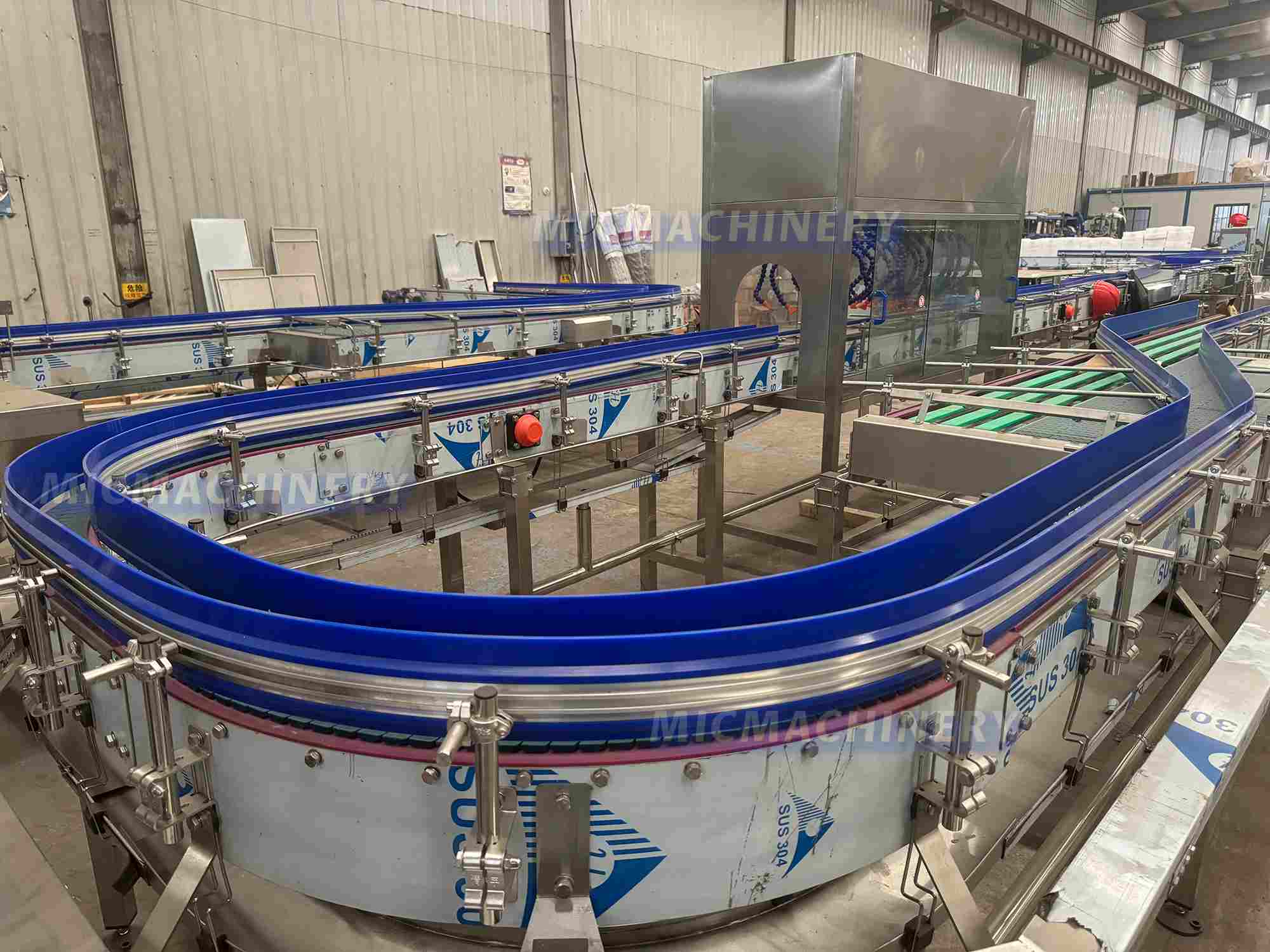

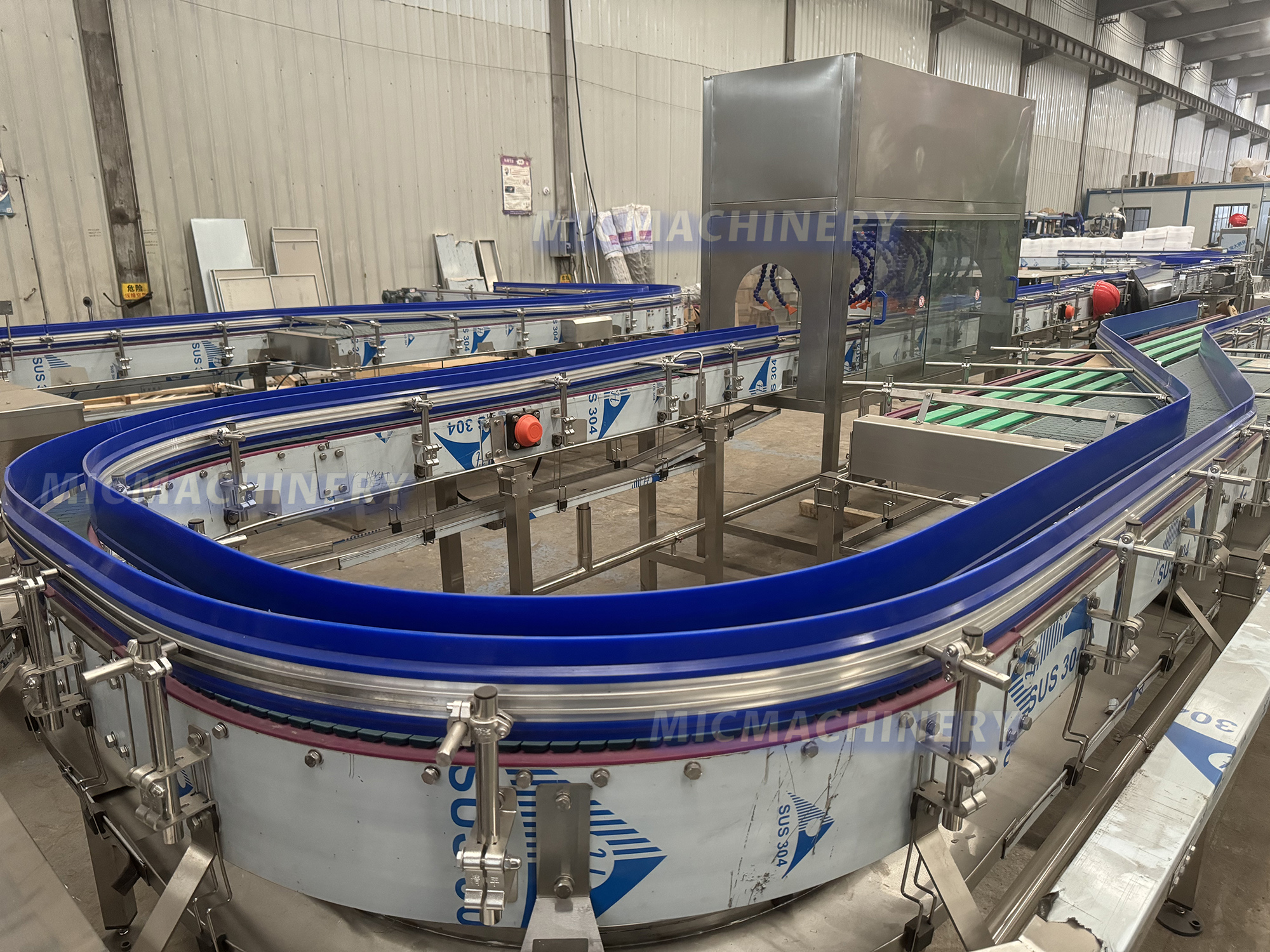

Conveyor System Optimize your water filling machine with a high-speed conveyor system for smooth and efficient bottle transportation. Designed for stability and durability, it ensures seamless movement through rinsing, filling, and capping stages. Ideal for packaged drinking water machine setups, it enhances automation and boosts production efficiency. |

|

Electrical Control Panel Optimize your water filling machine with a high-performance electrical control panel for precise automation and efficiency. Our advanced control systems ensure seamless operation, accurate filling, and energy savings. Designed for reliability, they enhance production stability in packaged drinking water machine setups. |

|

|

|

Capping part

- 304 stainless steel construction. No bottle no capping. Capping effect is stable and reliable |

Working Principle

1)The automatic water bottle filling machine integrates rinsing, filling, and capping into one streamlined operation.

2)Empty bottles are positioned by a rotary system and rinsed internally with filtered water to ensure cleanliness.

3)Clean bottles are transferred to the filling section, where a high-precision volumetric system dispenses water accurately into each container.

4)After filling, bottles move to the capping station, where the automatic water bottle filler applies caps securely.

5)The entire process is governed by an advanced PLC and touchscreen interface for fully automated and smooth operation.

Functional Advantages

▪ High-speed production line capable of handling up to 15,000 bottles per hour.

▪ Durable stainless-steel frame ensures sanitary compliance and long-term use.

▪ Tool-free adjustments allow quick changeovers for different bottle sizes.

▪ Integrated fault detection system ensures operational safety and machine longevity.

▪ Low energy consumption and reduced maintenance needs enhance overall efficiency.

Applications

The automatic water bottle filling machine is ideal for pure water, mineral water, and non-carbonated beverages. It is widely applied in medium to large-scale bottling plants, contract packaging facilities, and industrial drink manufacturers needing a reliable water bottle filling machine for high-volume output.

Conclusion

With cutting-edge technology and a proven track record, the MIC 40-40-10 stands out as a dependable automatic water bottle filler. Designed for consistency, hygiene, and speed, it’s the perfect solution for businesses looking to upgrade their water bottle filling machine systems with efficiency and confidence.

|

Model |

8-8-3 |

14-12-5 |

18-18-6 |

|

Application |

Juice, tea, pure water, mineral water, energy drinks, coffee and etc. |

||

|

Filling Way |

Gravity Filling |

||

|

Packing Type |

PET/Plastic bottle |

||

|

Production Capacity |

2000-2500BPH |

3000-5000BPH |

5000-8000BPH |

|

Powder |

1.2KW |

1.5KW |

2.2KW |

|

Weight |

1500KG |

2000KG |

4000KG |

|

Overall Dimensions(mm) |

2260*1600*2600 |

2250*1650*2650 |

2850*2150*2700 |

|

No. |

Name of parts |

Brand |

|

1 |

PLC |

Mitsubishi Japan |

|

2 |

Touch screen |

WEINVIEW |

|

3 |

Inverter |

Siemens Germany |

|

4 |

Low-voltage apparatus |

Schneider France |

|

5 |

Pneumatic components |

AirTAC Taiwan |

|

6 |

Bearing |

China |

|

7 |

Optical sensor |

Omron Japan |