Aluminum Foil Seal Leakage Detector

The aluminum foil seal leak detector is a system for checking leakage in plastic containers. This system effectively detects containers with leaks, such as cracks, seal leaks, or cracks in the aluminum foil seal and sidewalls. First, the system checks the leakage of plastic containers by measuring and comparing the liquid level of the bottle under pressure. The pressure measurement under compression is so precise that the device can detect leaks that are difficult to see with the naked eye but can cause early product deterioration. It can also check for overfilled or underfilled liquid levels, monitor filling machine valves, and cap machine heads.

Design Basis

During the packaging process, various packaging quality defects occur due to the stability of production equipment and the operational skills of the personnel. These defects can lead to the production of defective products, which ultimately affect product quality. Specific situations include:

| No. | Quality Defect | Risk | Explanation |

| 1 | Inadequate sealing | Material leakage | Cap sealing issues |

| 2 | Broken caps | Material leakage | Cap issues |

Currently, most manufacturers use manual visual inspection to control the above risks. However, manual inspection has significant limitations, as seen in the following drawbacks:

| No. | Drawback | Explanation |

| 1 | Fatigue leads to inconsistent accuracy | Greatly affected by line speed |

| 2 | Low precision, high uncertainty | Human error and inspection variance |

| 3 | Increasing labor costs | Additional labor required |

As shown, traditional manual inspection methods are difficult to achieve ideal results for various quality defects on the production line and cannot effectively control production risks.

Solution

According to the production process of the packaging line, automatic detection equipment is installed at appropriate positions to enable online automatic detection of each product. Defective products are automatically removed. The equipment list to be installed is as follows:

| No. | Installation Position | Equipment Name |

| 1 | After filling and capping | Aluminum foil seal leak detector |

By installing automated detection equipment, quality monitoring is achieved at each packaging stage, and defective products are removed in real time. In the event of abnormal production faults, a well-designed alarm system can promptly notify on-site operators to resolve the issues, ensuring production efficiency.

Advantages of Installing Online Detection Machines

| No. | Advantage | Explanation |

| 1 | High speed, high efficiency | Effectively replaces large amounts of manual labor in high-speed production lines |

| 2 | High precision | Effectively solves the low accuracy of manual inspection |

| 3 | Reliability guarantee | The overall operation of the equipment is more reliable than manual inspection |

| 4 | Production data management | Collects and analyzes production data, calculates the batch defect rate |

| 5 | Information management of the entire packaging line | Provides information management for post-production packaging |

These advantages go beyond just the inspection itself. Advanced automation equipment should be a key component of future smart factories, offering industrial Ethernet interfaces and multiple communication supports for future automation and network upgrades.

Product Features

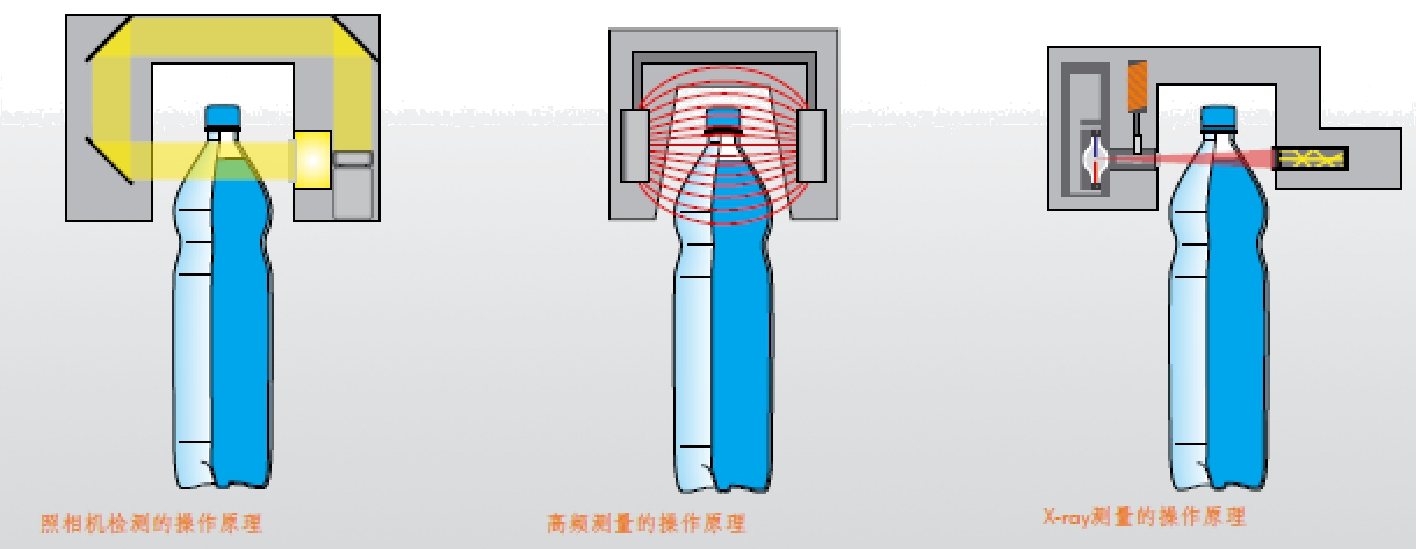

Leak detection can identify even the smallest leaks. Two measurement principles can be used, both equally accurate and effective:

1. The first method applies pressure to the container. If there is a leak, the liquid level rises more than a container without a leak. The liquid level is measured once without pressure and once under pressure, and the results are used to determine the leak level.

2. The second method uses pressure sensors to check the internal pressure of the container. After compressing the container for a period, containers without leaks have higher pressure than those with leaks.

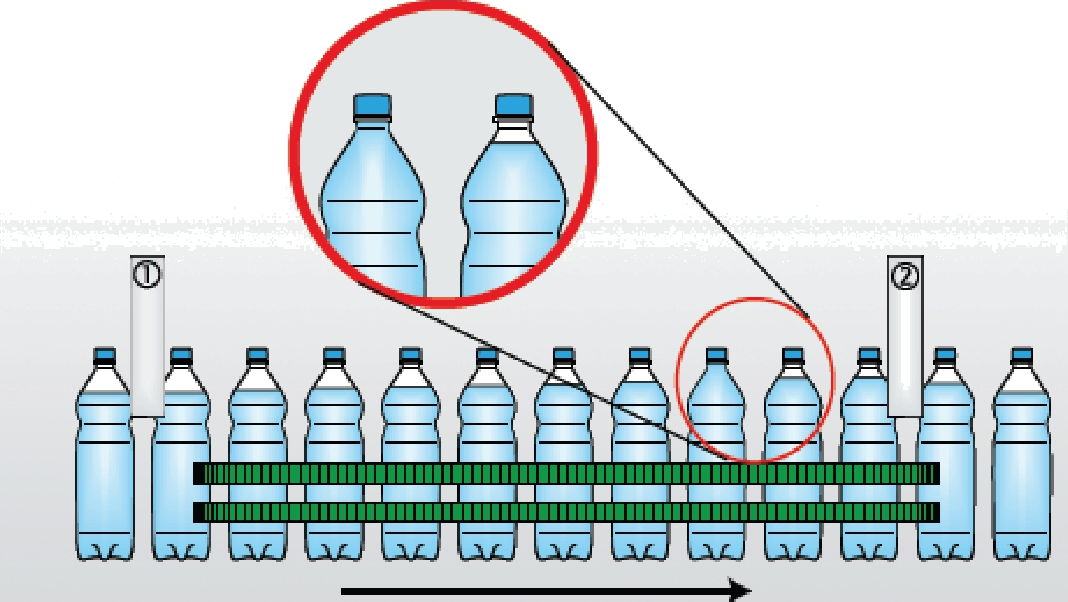

Squeeze Liquid Level Detection Principle Diagram:

• Mark position ①: Detect the initial liquid level.

• Mark position ②: Detect the liquid level after squeezing.

• The difference between the two measurements accurately determines whether there is a leak.

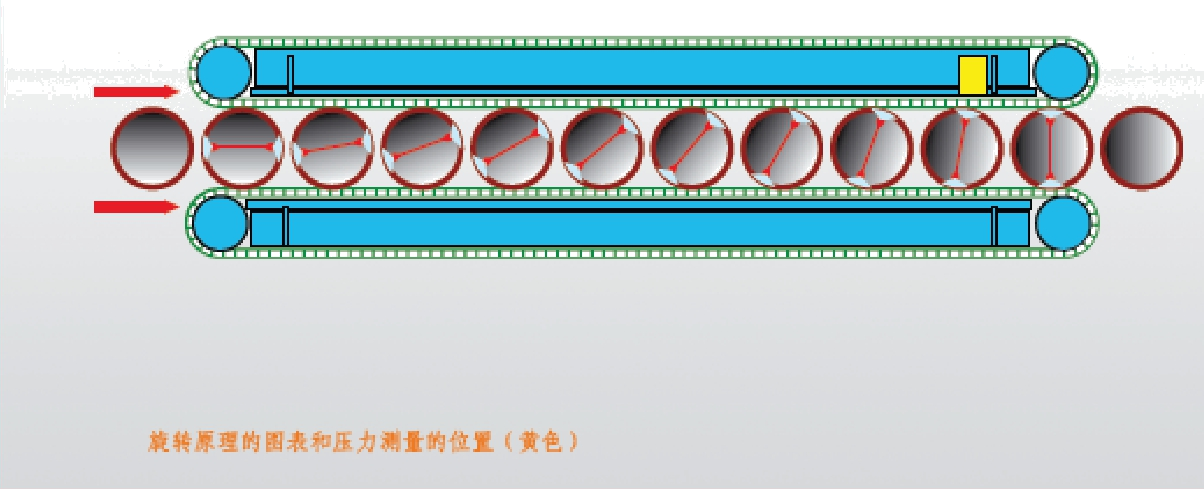

Internal Pressure Detection Principle:

When external pressure is applied, the container is compressed, generating internal pressure changes. These changes are sensitively detected by external pressure sensors in the yellow zone, enabling detection of even the smallest leaks. The application of pressure and simultaneous rotation of the container ensures a 360° inspection of the seal's tightness, effectively detecting containers that may not leak yet but already have the risk of leakage.