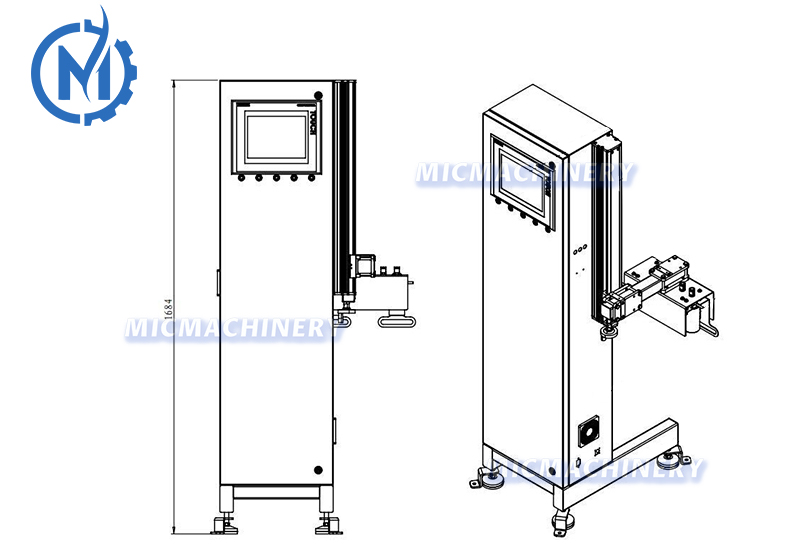

Automatic Vacuum Detection Machine

Automatic Vacuum Detection Machine: Ensuring Quality Control in Packaging

At Jiangsu Mic Machinery, we are committed to providing innovative solutions for the manufacturing and packaging industries. Our automatic vacuum detection machine is a cutting-edge piece of equipment designed to precisely monitor and control vacuum levels in packaging. It plays an essential role in maintaining product quality and ensuring the integrity of vacuum-sealed packages.

Machine Information

The vacuum detection machine is designed to detect and monitor vacuum levels within sealed packaging. Its high-precision sensors allow for real-time measurements, ensuring that each package meets the required vacuum standards. This machine is ideal for industries that rely on vacuum packaging, including food, pharmaceuticals, and electronics, where proper vacuum sealing is critical for preserving product freshness and safety.

Our vacuum detection equipment integrates seamlessly into existing production lines, offering a high level of automation to reduce manual intervention and increase production efficiency. With its intuitive controls and automated processes, this machine ensures accuracy and consistency in every packaging cycle.

Main Features

1、High-Precision Sensors: The core feature of the automatic vacuum detection machine is its advanced sensors. These sensors are capable of detecting even the slightest changes in vacuum levels, ensuring that only properly sealed packages move forward in the production line.

2、Real-Time Monitoring: The machine provides real-time feedback, allowing operators to monitor vacuum levels continuously. If any deviations from the set standards are detected, the system immediately alerts the operator, preventing faulty packaging from reaching customers.

3、Automated Operation: The vacuum detection machine operates autonomously, requiring minimal input from operators. This increases efficiency and reduces the chances of human error, allowing for faster production without compromising on quality.

4、Durable and Reliable: Built with high-quality materials and designed for long-term performance, the machine is capable of withstanding demanding production environments. Its robust construction ensures longevity, making it a wise investment for businesses looking to optimize their packaging processes.

5、User-Friendly Interface: The machine features an easy-to-use interface that simplifies setup and operation. Operators can quickly adjust settings, monitor the system, and perform maintenance tasks with ease, ensuring smooth operations at all times.

Conclusion

The automatic vacuum detection machine from Jiangsu Mic Machinery is a top-tier solution for manufacturers who prioritize quality control and precision in their packaging processes. With its high-precision sensors, real-time monitoring, and seamless integration into production lines, this vacuum detection equipment ensures that each product is properly sealed, preserving quality and extending shelf life.

By choosing Jiangsu Mic Machinery, you’re investing in state-of-the-art technology that enhances efficiency, minimizes errors, and guarantees the highest standards in vacuum packaging.

| Component | Brand | Origin |

|---|---|---|

| PLC Controller | Siemens | Germany |

| Touchscreen | Xinjie | Wuxi, China |

| Power Supply | Mingwei | Taiwan |

| Solenoid Valve | AIRTAC | Taiwan |

| Cylinder | AIRTAC | Taiwan |

| Proximity Switch | Omron | Japan |

| Encoder | Omron | Japan |

| Analysis Software | Self-developed | China |