MIC Beverage Bottling Line ( 200-800BPH)

MIC Beverage Bottling Line

Company Introduction:

Jiangsu Mic Machinery is a leading manufacturer of high-quality beverage filling and packaging machinery. With years of experience in the industry, we specialize in providing advanced and reliable equipment tailored to meet the unique needs of beverage producers worldwide. Our commitment to innovation, precision, and performance has established us as a trusted partner for businesses seeking efficient, high-quality beverage production line solutions. At Jiangsu Mic Machinery, we pride ourselves on offering the latest technologies that help improve production efficiency, reduce operational costs, and maintain the highest standards of product quality. Our beverage filling production line solutions are engineered to meet the diverse needs of the beverage industry, from small-scale bottling operations to large-scale production lines.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

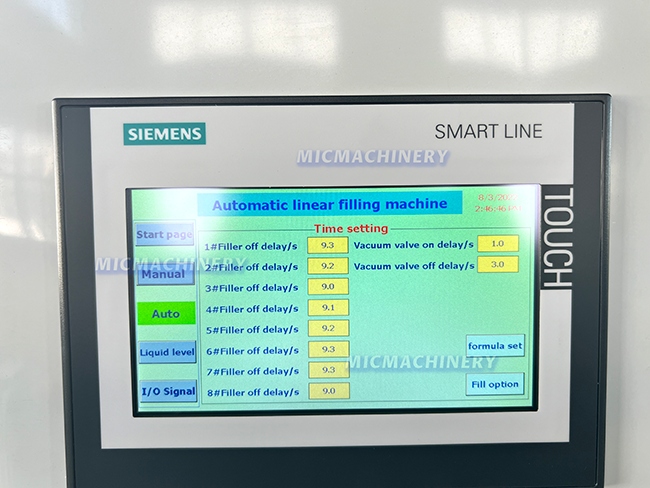

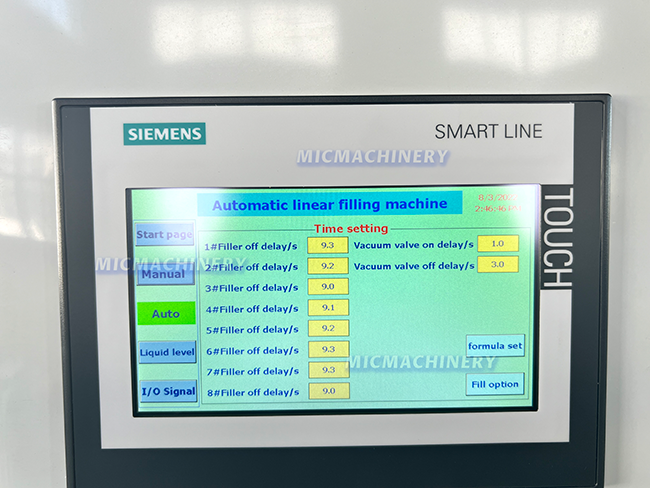

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Features:

The MIC Beverage Bottling Line is designed to deliver high-speed, high-efficiency, and seamless operations for beverage producers. Key features of this system include:

Multi-functional Capabilities: This line is capable of handling a wide range of beverages, from carbonated drinks and soft drinks to water and juices. The beverage production line is highly versatile and can easily be adapted to suit various beverage types and packaging formats.

Automated Filling and Capping: The beverage bottling line incorporates fully automated filling and capping processes. The filling station uses advanced technology to ensure precise and consistent filling volumes, while the capping station secures the caps onto the bottles with accuracy. This automation reduces the risk of human error and improves overall productivity.

Flexible Bottle and Can Handling: The system is designed to handle both bottles and cans in a wide variety of sizes, allowing businesses to easily adjust the line to suit their specific packaging requirements. The beverage filling production line includes adjustable conveyors and filling nozzles to accommodate different container formats.

High-Speed Performance: The MIC Beverage Bottling Line is engineered for high-speed production, ensuring fast turnaround times and minimal downtime. With robust mechanisms and optimized design, this system can process large volumes of beverages, making it ideal for businesses looking to scale their production efficiently.

Integrated Labeling and Packaging: In addition to filling and capping, the line also includes automated labeling and packaging systems. The labeling station ensures precise application of labels on each container, while the packaging system efficiently prepares the finished products for shipment.

User-Friendly Control System: The beverage production line is controlled through an intuitive touch-screen interface, allowing operators to easily monitor and control all aspects of the production process. The system is designed for ease of use, minimizing training time for operators and improving operational efficiency.

Stainless Steel Construction: Built with high-quality, durable materials, the line features stainless steel components that ensure long-lasting performance and easy cleaning. The materials used are resistant to corrosion, ensuring that the system remains in excellent condition even after extended use.

Advantages:

Increased Efficiency: The MIC Beverage Bottling Line is designed to streamline the entire bottling process, increasing overall production efficiency. The system automates many key tasks, reducing the need for manual labor and speeding up the production cycle.

High Precision and Consistency: With its advanced filling and capping technologies, the system ensures that each container is filled accurately to the desired volume, and caps are applied securely. This ensures product consistency and reduces waste, helping businesses maintain the quality of their beverages.

Flexible and Scalable: The beverage production line is highly adaptable to various beverage types and packaging sizes. Whether you’re bottling water, soft drinks, juices, or carbonated beverages, the line can be easily customized to meet specific production requirements. It’s also designed to scale up as production volumes increase, offering long-term flexibility for growing businesses.

Cost-Effective Solution: By reducing manual labor and improving production speeds, the beverage bottling line helps businesses save on operational costs. The automated processes also minimize errors and waste, resulting in higher production yields and lower material costs.

Space-Saving Design: The compact design of the beverage filling production line allows it to fit into a variety of production environments, even in spaces with limited floor area. Despite its small footprint, the system delivers high output, making it an excellent choice for businesses operating in confined spaces.

Reliability and Durability: Built to last, the MIC Beverage Bottling Line is designed for continuous operation. The high-quality materials and precision engineering ensure that the system operates reliably and efficiently, even under heavy production demands.

Reduced Maintenance Costs: With its durable construction and easy-to-maintain design, the beverage production line minimizes the need for frequent maintenance. The machine’s components are designed for easy access, ensuring that maintenance tasks can be performed quickly, reducing downtime and associated costs.

In conclusion, the MIC Beverage Bottling Line is an ideal solution for businesses looking to optimize their bottling and packaging operations. Whether you’re producing water, soft drinks, juices, or carbonated beverages, this system offers flexibility, efficiency, and high-quality performance to meet the demands of the beverage industry. With its advanced features and cost-saving advantages, it’s an investment that ensures long-term success in the competitive beverage market.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |