MIC Beverage Filling Machine Manufacturers ( 200-800BPH)

Company Introduction

Jiangsu Mic Machinery is a leading manufacturer and supplier of cutting-edge beverage filling machines designed to meet the evolving needs of the beverage industry. As a trusted beverage packaging machine manufacturer, we specialize in providing high-quality, innovative solutions for filling, capping, and packaging a wide variety of beverages. Our machines are known for their precision, efficiency, and durability, making us a preferred partner for beverage producers worldwide. With years of expertise and a commitment to excellence, Jiangsu Mic Machinery continues to deliver exceptional products that enhance the productivity and reliability of beverage manufacturing operations.

|

|

Capping Head A Capping Head is an essential component in packaging machinery, used to securely seal bottles, jars, and other containers with various types of caps, ensuring product integrity and safety. |

|

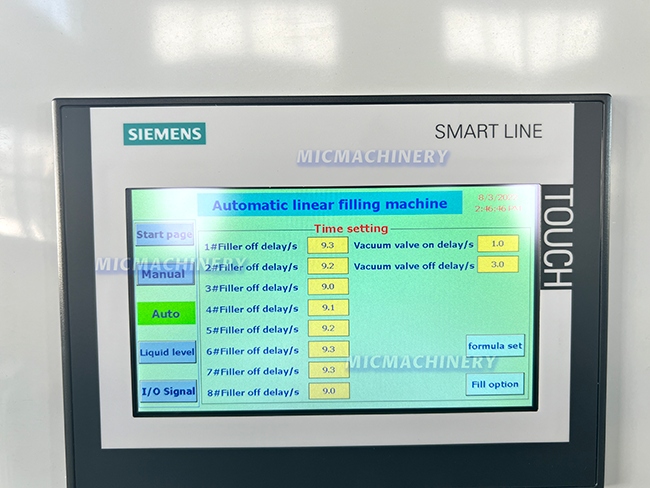

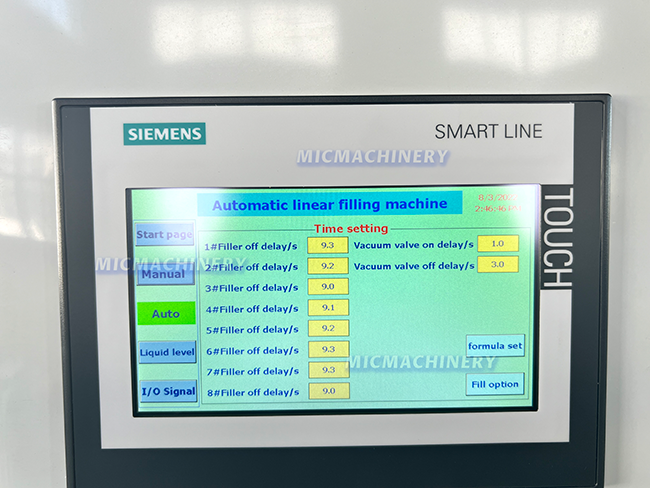

Control panel A Control Panel is a user interface in machinery that allows operators to monitor and control machine functions, adjusting settings for optimal performance, safety, and efficiency in production.

|

|

|

|

Filling Head A Filling Head is a key component in filling machinery, responsible for accurately dispensing liquids or powders into containers. It ensures precise filling levels, improving efficiency and minimizing waste during production. |

Features of Beverage Filling Machine

Our beverage filling machines are engineered with advanced technology and designed to streamline the beverage filling process. Some key features include:

1、Versatility in Beverage Types

The beverage filling machine can handle a wide range of beverages, from carbonated drinks to non-carbonated liquids like juices and teas. This versatility makes it an ideal choice for businesses with diverse production needs.

2、Precision and Consistency

The machine is equipped with a precise volumetric filling system, ensuring each container is filled with an accurate volume of liquid. This minimizes waste and ensures consistent quality in every batch.

3、Advanced Control Systems

Our machines feature an intuitive control panel that allows for easy adjustments, ensuring that the filling process is tailored to specific product types and production volumes.

4、High-Speed Operation

Designed for high efficiency, the beverage packaging machine operates at impressive speeds, ensuring that manufacturers can meet tight production schedules without compromising on quality.

5、Durability and Reliability

Built with high-quality materials, our machines are designed to withstand the demands of continuous production while maintaining optimal performance over the long term.

6、Seamless Integration

The beverage filling machine integrates seamlessly with other beverage packaging machines such as capping and labeling machines, ensuring a smooth and efficient production line.

7、User-Friendly Interface

With easy-to-use controls, operators can quickly set up the machine, making it accessible even to those with minimal technical experience.

Advantages of Beverage Filling Machine

Increased Productivity: The beverage packaging machine is designed to maximize throughput, ensuring that production rates meet or exceed your business needs. With faster filling speeds, your production line becomes more efficient.

1)Improved Accuracy: The machine's volumetric filling system ensures that each container receives the exact amount of beverage, reducing product wastage and increasing cost-effectiveness.

2)Flexibility: Whether you're filling small bottles or large containers, the beverage filling machine is adaptable to various container sizes and shapes, making it a great fit for businesses with diverse packaging requirements.

3)Lower Operational Costs: The automation of the filling process reduces the need for manual labor, thus lowering overall operational costs. Additionally, the efficient use of resources minimizes waste, helping your business save on material costs.

4)Enhanced Product Quality: With precise filling and an automated process, the quality of each product is maintained consistently. This results in a uniform look and taste for each beverage, which is essential for brand reputation.

5)Easy Maintenance: Designed with ease of maintenance in mind, our beverage filling machines have accessible components and require minimal downtime for servicing, ensuring smooth operations throughout the year.

6)Space-Efficient Design: The compact design of the machine allows it to fit seamlessly into various production environments, making it a valuable addition to both small and large-scale production facilities.

7)Reliable after-Sales Support: As a reputable beverage filling machine manufacturer, Jiangsu Mic Machinery offers comprehensive customer support, including machine installation, maintenance, and troubleshooting, ensuring your equipment operates at peak performance for years.

In conclusion, the MIC Beverage Filling Machine offers exceptional features, enhanced productivity, and a wide range of benefits that make it an indispensable part of any beverage production line. Whether you’re looking to increase efficiency, improve accuracy, or reduce operational costs, our machines are engineered to help you achieve your goals with minimal effort. At Jiangsu Mic Machinery, we are committed to delivering high-quality beverage packaging machines that elevate your business to new levels of success.

| Power | 0.3Kw |

| Filling heads | 4-10 heads |

| Capping heads | 4-10 heads |

| Production capacity | 200-800CPH |

| Bottle diameter range | Ф50-90MM |

| Bottle height | 150-300MM |

| Dimension | 2000*700*2000mm |

| Weight | 150Kg |

|

1 |

Name |

Brand |

|

2 |

Push Button |

Schneider France |

|

3 |

Electromagnetic Contactor |

Schneider France |

|

4 |

Relays |

Omron Japan |

|

5 |

Frequency Converter |

Siemens |

|

6 |

Air Cylinder |

AirTAC Taiwan |

|

7 |

Electromagnetic Valve |

AirTAC Taiwan |

|

8 |

PLC Control System |

Siemens |

|

9 |

Touch Screen |

Siemens |

|

10 |

Photoelectric Switch |

Autonics |

|

11 |

Proximity Switch |

Autonics |

|

12 |

Reducer |

Zhejiang Duoli China |

|

13 |

Sealing Motor |

Zhejiang Duoli China |

|

14 |

Barometer |

AirTAC Taiwan |

|

15 |

Bearing |

Harbin China |