Double Effect Falling Film Evaporator

Double Effect Falling Film Evaporator

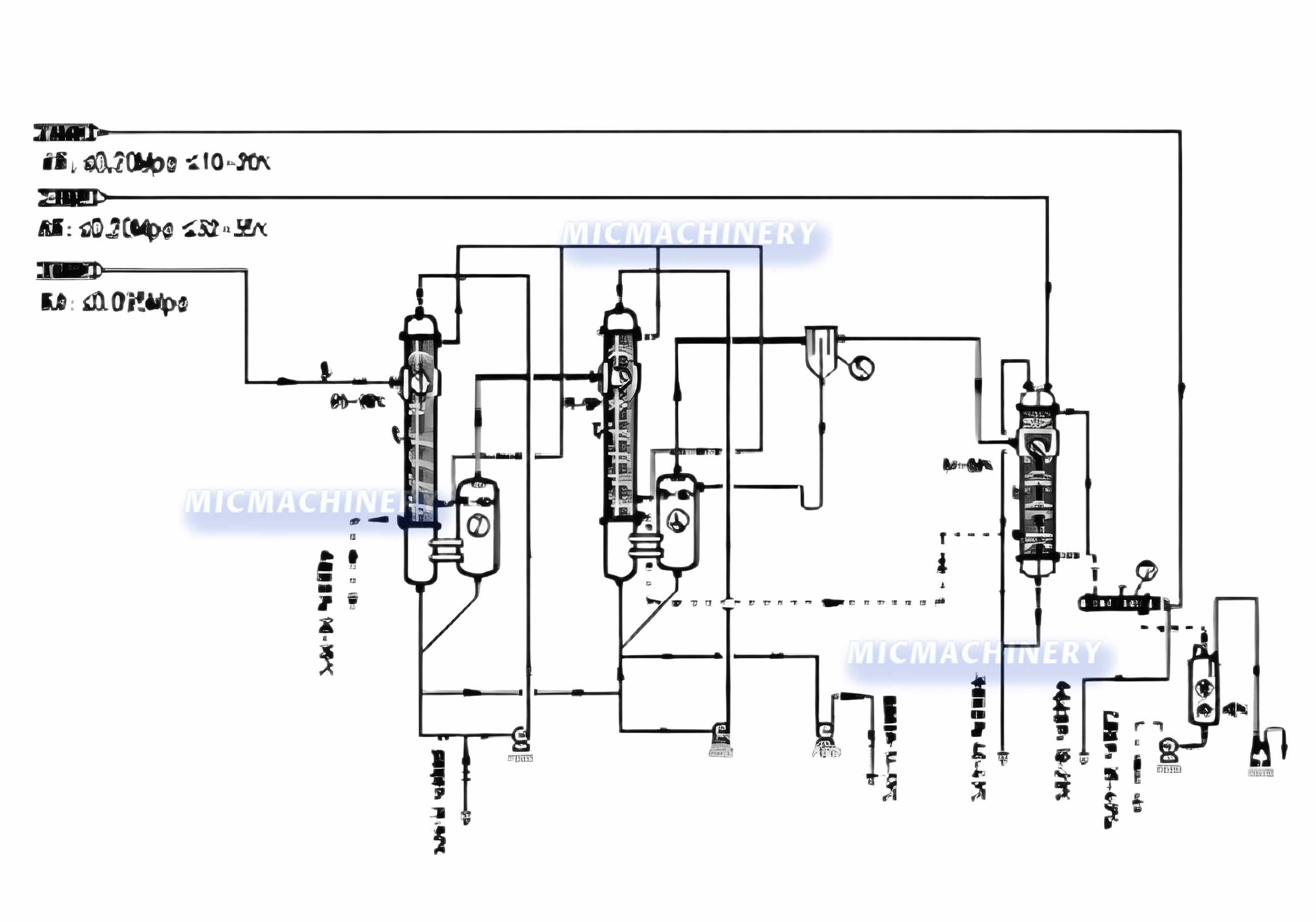

The double effect falling film evaporator is an advanced industrial evaporation system designed to improve efficiency in the concentration of liquids. By utilizing a two-stage evaporation process, it significantly reduces energy consumption while maintaining high throughput and product quality. This equipment is widely used in the pharmaceutical, chemical, and food industries.

High Efficiency and Energy Saving

The falling film double effect evaporator ensures rapid heat transfer and gentle processing of heat-sensitive liquids such as juices, herbal extracts, milk, and chemical solutions. Its dual-effect design allows the reuse of latent heat from the first effect in the second stage, achieving energy savings while maintaining stable operation.

Durable Construction and Reliable Performance

Built with high-quality stainless steel, the double effect falling film evaporator is corrosion-resistant and easy to clean. Its vertical tube structure supports continuous processing, minimizes scaling, and ensures uniform evaporation. The system is equipped with advanced controls for temperature, pressure, and liquid flow, guaranteeing precision and safety.

Applications

• Food & Beverage Industry: Concentration of fruit juices, syrups, dairy products, and beverages

• Pharmaceutical Industry: Concentrating herbal extracts, medicinal solutions, and active ingredients

• Chemical Industry: Solvent recovery, chemical solution concentration, and industrial liquid processing

Competitive Double Effect Falling Film Evaporator Price

We provide this high-performance double effect falling film evaporator at a competitive double effect falling film evaporator price, ensuring excellent value without compromising quality. Its energy-efficient design and durable construction offer long-term cost savings and reliable operation.

Key Features

1. Dual-effect operation maximizes steam utilization and reduces energy consumption.

2. Fully enclosed production, rapid, low-temperature evaporation, maintaining the natural color, aroma, and flavor of the product.

3. High heat transfer efficiency: Rapid material flow and strong anti-scaling capabilities.

4. Wide adjustable concentration ratio range: Because each effect can form a separate material circulation, the concentration ratio can be adjusted over a wide range.

5. The equipment is equipped with cleaning nozzles and a CIP internal cleaning system.

Choose the double effect falling film evaporator for efficient concentration, energy savings, and high product quality. With a competitive double effect falling film evaporator price, it is an ideal solution for modern industrial production lines.

| Project | MIC2-100 | MIC2-200 | MIC2-400 | MIC2-600 | MIC2-800 | MIC2-1000 | MIC2-1200 |

| Ethanol evaporation capacity (kg/h) | 100 | 200 | 400 | 600 | 800 | 1000 | 1200 |

| A Heating source medium | Steam | ||||||

| Raw steam pressure (Mpa) | 0.095 (Absolute pressure) | ||||||

| Steam heat consumption (kcal/h) | 17100 | 34200 | 68400 | 102600 | 136800 | 171000 | 205200 |

| B Heating source medium | Heat transfer oil | ||||||

| Heat transfer oil inlet and outlet temperature (°C) | 120-130/100-110 | ||||||

| Heat consumption of heat transfer oil (kcal/h) | 18000 | 36000 | 72000 | 108000 | 144000 | 180000 | 216000 |

| Working pressure of heat transfer oil (Mpa) | 0.15-0.20 | ||||||

| Ⅰefect evaporation (kg/h) | 51.8 | 103 | 207 | 310 | 414 | 518 | 622 |

| Ⅱefect evaporation (kg/h) | 48.2 | 97 | 193 | 290 | 386 | 482 | 578 |

| Steam condensate volume (kg/h) | 32 | 63 | 127 | 190 | 253 | 317 | 380 |

| Ⅰefect evaporation temperature (°C) | 75-80 | ||||||

| Ⅱ efect evaporation temperature (°C) | 55-60 | ||||||

| Ⅰeffect vacuum degree (-Mpa) | 0.053-0.063 | ||||||

| Ⅱ effect vacuum degree (-Mpa) | 0.081-0.085 | ||||||

| Ethanol discharge temperature (°C) | 35-40 | ||||||

| Ⅱ effect concentrated liquid discharge temperature (℃) | 54-59 | ||||||

| Ⅰeffect design heating area (㎡) | 2.0 | 4.0 | 8.0 | 12 | 16 | 20 | 22 |

| Ⅱ effect design heating area (㎡) | 3.0 | 6.0 | 13 | 18 | 28 | 30 | 34 |

| Condensing area (㎡) | 3.5 | 7.0 | 15 | 20 | 30 | 35 | 40 |

| Condenser working pressure (Mpa) | 0.20-0.25 | ||||||

| Cooling area (㎡) | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 8.0 | 10 |

| Cooler working pressure (Mpa) | 0.15-0.20 | ||||||

| Cooling water circulation (t/h) | 2.0 | 4.0 | 7.5 | 11 | 16 | 20 | 22 |

| Cooling water working pressure (Mpa) | 0.20-0.25 | ||||||

| Cooling water inlet and outlet temperature (°C) | 32-35/40-43 | ||||||

| Chilled water consumption (kcal/h) | 1500 | 3000 | 6000 | 9000 | 12000 | 15000 | 18000 |

| Chilled water inlet and outlet temperature (°C) | 10-20/18-28 | ||||||

| Chilled water working pressure (Mpa) | 0.15-0.20 | ||||||

| Total installed power (kw/h) | 4.5 | 5.55 | 6.65 | 8.85 | 10.7 | 12.5 | 12.5 |